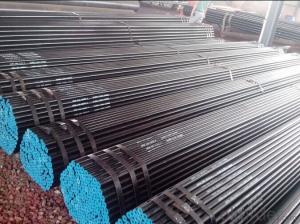

Good Quality Seamless Carbon And Alloy Steel Mechanical Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Good Quality Seamless Carbon And Alloy Steel Mechanical Tubing

ASTM A179 Seamless Carbon and Alloy Steel Mechanical Tubing

JIS G3441 Alloy steel tubes for machine purposes

MECHANICAL SEAMLESS STEEL TUBING

Usage: Applicable to the general structure, mechanical structure with seamless steel tubes.

Quality Standard:

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

GB/T8162 Seamless Steel Tubes for Structural Purposes

JIS G3441 Alloy steel tubes for machine purposes

JIS G3444 Carbon steel tubes for general structural purposes

JIS G3445 Carbon steel tubes for machine structural purposes

DIN 2391 Seamless Precision Steel Tubes

EN10305 Steel tubes for precision applications. Technical delivery conditions. Seamless cold drawn tubes

EN 10210:Seamless structural steel pipes

- Q: How are steel pipes used in the manufacturing of power plants?

- Steel pipes are extensively used in the manufacturing of power plants for various applications such as transporting water, steam, and other fluids, as well as for structural purposes. They are commonly used for the construction of boiler tubes, heat exchangers, condensers, and steam distribution systems. Additionally, steel pipes are essential for conveying fuel gases and air in power plants, ensuring efficient operation and safety.

- Q: Can steel pipes be used for structural applications?

- Yes, steel pipes can be used for structural applications.

- Q: How do you calculate the stress in a steel pipe?

- When calculating the stress in a steel pipe, it is necessary to take into account the steel's material properties and the external forces acting upon the pipe. The stress in the pipe is typically determined using the following equation: Stress = Force / Area Initially, the force acting on the pipe must be established. This force may stem from external loads such as pressure, weight, or mechanical forces. The force can be calculated by multiplying the pressure or weight by the surface area it acts upon. For instance, if the pipe is subjected to internal pressure, the force can be determined using the equation: Force = Pressure x Area Subsequently, the cross-sectional area of the pipe needs to be determined. The cross-sectional area of a circular pipe can be calculated using the formula: Area = π x (Diameter / 2)^2 Once the force and area have been determined, the stress can be calculated by dividing the force by the area. This calculation will yield the stress value in units like pounds per square inch (psi) or newtons per square meter (Pa). It is important to bear in mind that the stress calculation assumes that the pipe is in a state of equilibrium and that the material properties of the steel are known. The material properties, such as yield strength and ultimate tensile strength, are utilized to ensure that the calculated stress does not exceed the steel's maximum capacity.

- Q: Are steel pipes suitable for underground gas distribution?

- Yes, steel pipes are suitable for underground gas distribution. They have a high tensile strength, corrosion resistance, and can withstand extreme temperatures, making them an ideal choice for transporting natural gas underground. Additionally, steel pipes are durable and have a long lifespan, making them a reliable option for gas distribution systems.

- Q: How are steel pipes measured and categorized?

- Steel pipes are typically measured and categorized based on their outer diameter (OD) and wall thickness. The OD is measured in inches or millimeters, while the wall thickness is measured in inches or centimeters. Pipes are further categorized based on their schedule, which refers to the wall thickness and determines the pressure rating of the pipe. The schedule is denoted by a letter or number, such as Schedule 40 or Sch 80. These measurements and categorizations help in selecting the appropriate steel pipe for different applications and ensure compatibility with fittings and other components.

- Q: How are steel pipes protected during transportation?

- To ensure the safety and integrity of steel pipes during transportation, various measures are taken. One effective approach involves applying protective coatings to the pipes' exteriors. These coatings, such as epoxy or polyethylene, act as barriers against moisture, corrosion, and physical damage. Additionally, bundling the pipes together and securing them with strapping or bands prevents movement and potential collisions while in transit. To provide extra protection against impact and handling, wooden crates or containers may also be used. Furthermore, careful loading and unloading procedures are followed to minimize stress or strain on the pipes. By implementing these protective measures, steel pipes can safely reach their destination without compromising their quality or structural integrity.

- Q: Can steel pipes be used for conveying solid materials?

- Yes, steel pipes can be used for conveying solid materials. Steel pipes are known for their durability and strength, making them suitable for transporting various solid materials such as ores, grains, coal, and construction materials. The smooth interior of steel pipes allows for efficient flow and minimal friction, making them a preferred choice in industries like mining, agriculture, and construction.

- Q: What is the difference between API 5L and ASTM A106 steel pipes?

- API 5L and ASTM A106 steel pipes are both widely used in the oil and gas industry, but they have some key differences. API 5L is a specification for seamless and welded steel pipes used for pipeline transportation systems in the petroleum and natural gas industries. It covers various grades of carbon and alloy steel pipes, with different strength levels and impact requirements. API 5L pipes are designed for conveying fluids, such as oil, gas, and water, over long distances. On the other hand, ASTM A106 is a specification for seamless carbon steel pipes used for high-temperature service. It covers seamless pipes for pressure and mechanical applications, including transportation of fluids and gases in industries like refineries, power plants, and boilers. While both API 5L and ASTM A106 pipes are used in similar applications, the main difference lies in their intended use and the specific requirements they must meet. API 5L pipes are primarily used for pipeline transportation systems, whereas ASTM A106 pipes are more focused on high-temperature service applications. Additionally, the manufacturing processes and testing requirements for both specifications may vary.

- Q: RC is it welded steel pipe or galvanized steel pipe?

- The basic knowledge of wire tubes - wire tubes, SC is welded steel pipe, RC is galvanized steel pipeThe basic wire pipe is the minimum requirement in the steel pipe. For so long, I wonder if you will adopt it

- Q: How are steel pipes used in automotive manufacturing?

- Steel pipes are commonly used in automotive manufacturing for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and corrosion resistance, making them suitable for withstanding the harsh conditions and high temperatures associated with automotive operations. Additionally, steel pipes offer flexibility in design and can be easily formed and manipulated to meet specific requirements, ensuring efficient and reliable performance in vehicles.

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 1991 |

| Annual Output Value | 300,000Tons |

| Main Markets | Europe; Southeast Asia; etc. |

| Company Certifications | API 5L;API 5CT;API Q1;ISO/TS29001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wuxi; Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3900-4000 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 450,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Good Quality Seamless Carbon And Alloy Steel Mechanical Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords