Seamless Boiler Tube 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Standard:JIS G3461-2005,JIS G3454-2007,JIS G3456-2004,GB/T 8163-1999,DIN 1629/4...

2.Technique:Hot Rolled

Detail specification:

1,Standard: GB5310-2008

2,Material:a, High quality carbon structural steel grade: 20G, 20MnG,25MnG

b, Alloy steel grade: 15MoG,20MoG,12CrMoG,15CrMoG,12Cr2MoG,12CrMoVG,12Cr3MoVSiTiB

c, Heat resistant steel: 1Cr18Ni9,1Cr18Ni11Nb

3,Outside diameter:hot-rolled pipe is 22~530mm

cold-rolled pipe is: 10~108mm

4, Wall thickness: hot-rolled pipe is 20~70mm

cold-rolled pipe is: 2.0~13.0mm

5, Applications: Low and middle pressure fluid pipeline, boiler, petroleum and natural gas industry, drilling, chemical industry, electric industry, shipbuilding, fertilizer equipment and pipeline, structure, petrochemical, pharmaceutical industry

Mechanical Property:

Chemical Component:

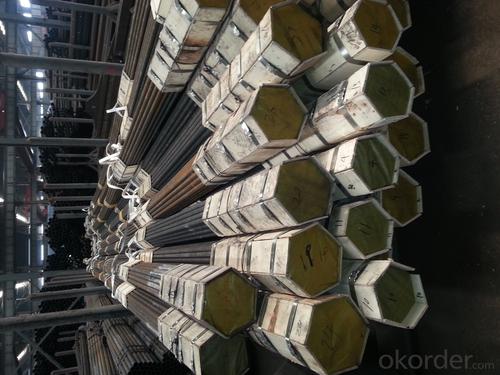

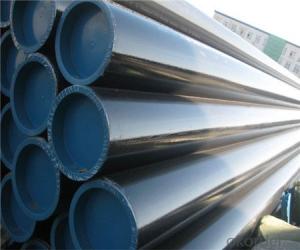

Seamless Boiler Tube Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q: How do you determine the maximum allowable stress for a steel pipe?

- To determine the maximum allowable stress for a steel pipe, several factors need to be considered. These include the material properties of the steel, such as its yield strength, ultimate tensile strength, and elongation. Additionally, the pipe's dimensions, wall thickness, and the intended application or service conditions must be taken into account. By considering these factors, along with relevant design codes and standards, engineers can calculate the maximum stress that the steel pipe can safely withstand without experiencing failure.

- Q: How are steel pipes used in water transportation?

- Steel pipes are commonly used in water transportation due to their durability and strength. They can be used for various purposes, such as carrying water from a source to a treatment plant, distributing water to different areas, and even for sewage systems. Steel pipes are highly resistant to corrosion and can withstand high pressure, making them ideal for long-distance water transportation.

- Q: Can steel pipes be used for natural gas distribution?

- Yes, steel pipes can be used for natural gas distribution. Steel pipes are commonly used for this purpose due to their durability, strength, and ability to withstand high pressure and extreme temperatures. Additionally, steel pipes are resistant to corrosion, making them suitable for transporting natural gas over long distances.

- Q: What are the different end types for steel pipes?

- Steel pipes can have various end types, each designed for a specific purpose. Some common end types include: 1. Plain End: This is the simplest type, with no threading or special treatment. It is used for non-threaded applications or when welding is required. 2. Threaded End: These ends have male threads on one or both sides, allowing for easy connection with other threaded fittings or pipes. They are commonly used in plumbing and gas applications that require easy assembly and disassembly. 3. Beveled End: Beveled ends are cut at an angle (usually 30 or 45 degrees) to facilitate welding. The smooth transition between the pipe and the weld joint ensures a strong connection. They are used in construction, oil and gas, and pipeline industries. 4. Coupling End: These ends have female threads on both sides, enabling the joining of two pipes with a coupling or fitting. They are often used in plumbing systems or for easily disassembling pipe sections. 5. Flanged End: Flanged ends have a flared or raised lip on one or both sides, allowing for easy attachment to other flanged components like valves or pumps. They are commonly used in industrial applications requiring secure connections. 6. Socket Weld End: These ends have a socket or recess on one or both sides, allowing for easy connection with socket weld fittings. They provide a strong joint and are commonly used in high-pressure applications, such as petrochemical or power plants. These examples demonstrate the variety of end types available for steel pipes. The choice depends on specific application requirements, including the need for easy assembly, disassembly, or compatibility with other fittings.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on the specific application and industry standards. However, common dimensions include outer diameter (OD) and wall thickness (WT). For instance, a standard steel pipe might have an outer diameter ranging from 0.84 inches to 24 inches, and a wall thickness varying from schedule 5 to schedule 160.

- Q: How are steel pipes used in the manufacturing of furniture and appliances?

- Due to their strength, durability, and versatility, steel pipes find widespread use in the production of furniture and appliances. In furniture manufacturing, they are commonly employed to construct the frames and structures of various pieces, including chairs, tables, and beds. Serving as the primary support system, these pipes ensure a sturdy and dependable foundation for the furniture. In appliances, steel pipes serve multiple purposes. They are frequently utilized to create the internal framework and bear the weight of kitchen appliances such as stoves, ovens, and refrigerators. Additionally, steel pipes are commonly found in washing machines, dryers, and dishwashers, facilitating the transportation of water and other fluids throughout the appliance. Moreover, steel pipes are essential in the manufacture of outdoor furniture and equipment that require weather resistance and durability. To safeguard against rust and corrosion, these pipes are often coated with protective materials, thus ensuring the longevity of the furniture and appliances. In conclusion, steel pipes play a vital role in the production of furniture and appliances, providing the necessary strength and support. Their versatility allows for various applications, making them an indispensable component in the manufacturing process of these goods.

- Q: Can steel pipes be used for firefighting systems?

- Indeed, firefighting systems can utilize steel pipes. Steel pipes are frequently chosen for their robustness and ability to endure high temperatures, making them ideal for transporting water and other fire-suppressing agents. Typically, these pipes are employed in larger commercial or industrial structures that necessitate a larger flow rate and pressure for their fire protection systems. Additionally, steel pipes possess the benefit of withstanding external forces and impacts, thus ensuring the integrity of the firefighting system. Moreover, steel pipes offer the convenience of easy connection, simplifying installation and maintenance procedures. Nonetheless, it is crucial to ensure that the steel pipes employed in firefighting systems undergo appropriate treatment to prevent corrosion and rusting, as these factors may compromise their effectiveness during emergency situations. Regular inspections and maintenance are necessary to guarantee the reliability and functionality of the steel pipes within the firefighting system.

- Q: How do steel pipes resist corrosion?

- Steel pipes resist corrosion through various methods, primarily due to the protective properties of the material itself. Firstly, steel contains a small amount of carbon, which creates a thin, invisible layer on the surface of the pipe known as a passive film. This film acts as a barrier, preventing oxygen and moisture from reaching the underlying steel and thus inhibiting corrosion. Additionally, steel pipes are often coated with protective materials such as zinc, epoxy, or polyethylene, which provide an additional layer of defense against corrosion. Regular maintenance and inspections also play a crucial role in preventing corrosion by identifying and addressing any potential vulnerabilities in the pipes.

- Q: Can steel pipes be used for transporting chemicals?

- Yes, steel pipes can be used for transporting chemicals. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for handling various chemicals. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring safe transportation of chemicals.

- Q: Are steel pipes resistant to UV degradation?

- In general, steel pipes lack resistance to UV degradation. When exposed to ultraviolet (UV) radiation for extended periods, steel pipes may experience different types of degradation. The steel can become prone to brittleness, resulting in cracks and potential failure. Moreover, UV radiation can induce corrosion and discoloration on the surface of the steel pipes. To counteract the effects of UV degradation, it is possible to apply protective coatings or paint to create a barrier against UV radiation. Regular maintenance and inspections are crucial to detect any indications of UV degradation and implement necessary actions to prevent further deterioration.

Send your message to us

Seamless Boiler Tube 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords