S35C Forged Alloy Steel Round Bars with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

C | Si | Mn | P | S | Ni | Cr | Cu |

0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications:

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

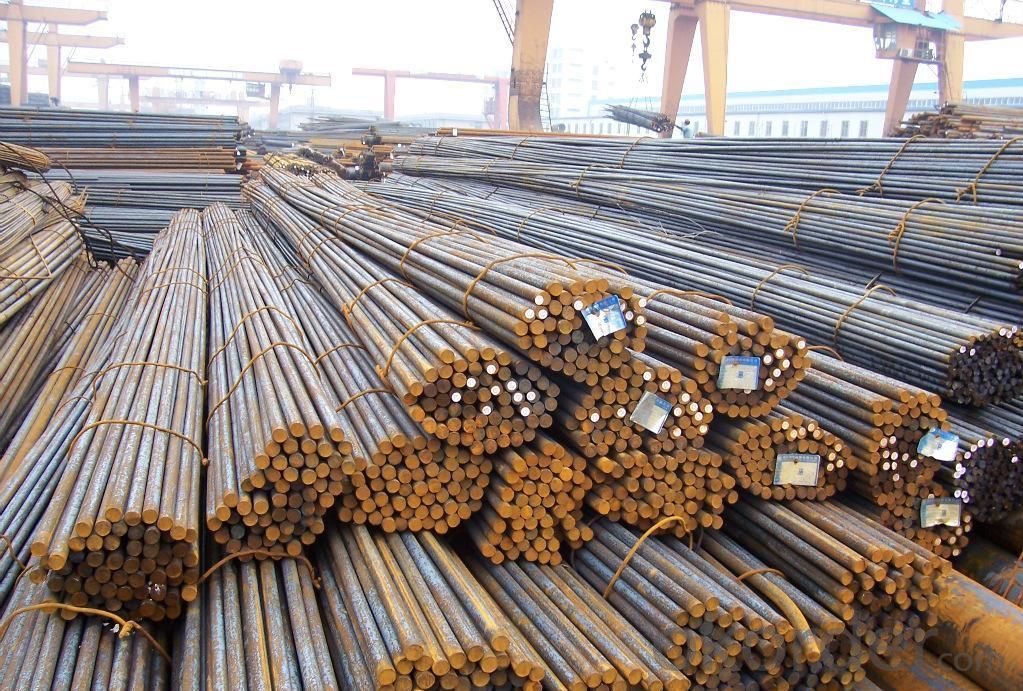

Main product pictures:

- Q: How does special steel perform in terms of creep resistance at elevated temperatures?

- Special steel has excellent creep resistance at elevated temperatures. Its unique composition and heat treatment processes enable it to maintain its strength and dimensional stability over prolonged periods of exposure to high temperatures. This makes special steel highly reliable and suitable for applications where resistance to creep deformation is crucial, such as in power generation plants, aerospace, and oil and gas industries.

- Q: What is the role of special steel in sustainable manufacturing?

- Special steel plays a crucial role in sustainable manufacturing by offering enhanced durability, strength, and corrosion resistance, resulting in longer-lasting and more efficient products. It enables the development of lightweight yet robust components, reducing material consumption and energy consumption during production and usage. Additionally, special steel can be easily recycled, contributing to the circular economy and minimizing environmental impact.

- Q: How does special steel contribute to the tool manufacturing industry?

- Special steel plays a crucial role in the tool manufacturing industry as it offers several advantages that enhance the quality, performance, and durability of tools. Firstly, special steel is known for its exceptional strength and toughness, which makes it ideal for manufacturing high-quality tools that can withstand heavy usage and extreme conditions. In addition to strength, special steel also offers excellent wear resistance. Tools made from special steel can retain their sharpness and cutting edge for a longer period, reducing the need for frequent re-sharpening or replacement. This not only saves time and effort but also increases productivity in various industries that heavily rely on tools, such as construction, automotive, and aerospace. Moreover, special steel can be heat-treated to achieve specific properties, such as hardness, which is vital for tools like drills, saws, and blades. This heat treatment process allows manufacturers to tailor the steel's characteristics to meet the specific requirements of different tools, ensuring optimal performance and effectiveness. Special steel also provides corrosion resistance, an essential feature for tools that may be exposed to moisture, chemicals, or harsh environments. By preventing rust and corrosion, special steel helps to prolong the lifespan of tools, reducing maintenance costs and ensuring their reliable performance over time. Furthermore, the versatility of special steel allows manufacturers to create tools with complex shapes and designs. This flexibility opens up opportunities for innovation and the development of specialized tools that cater to unique applications and industries. Special steel can be easily machined, welded, and formed into various tool designs, enabling manufacturers to create efficient and ergonomic tools that offer improved handling and user comfort. In summary, special steel significantly contributes to the tool manufacturing industry by providing strength, wear resistance, heat treatability, corrosion resistance, and versatility. These properties enable the production of high-quality tools that are durable, reliable, and efficient, meeting the demands of diverse industries and enhancing productivity.

- Q: What are the different methods for improving the impact resistance of special steel?

- There are several methods for improving the impact resistance of special steel. One commonly used method is through heat treatment processes such as quenching and tempering, which involve rapid cooling of the steel followed by controlled heating and cooling to achieve desired mechanical properties. Another method is alloying, where elements such as nickel, chromium, and molybdenum are added to the steel to enhance its toughness and resistance to impact. Additionally, processes like shot peening and surface hardening can be employed to increase the steel's resistance to impact by inducing compressive stresses on its surface.

- Q: How does the composition of special steel affect its properties?

- The composition of special steel greatly affects its properties. By adjusting the levels of various elements such as carbon, chromium, manganese, and nickel, the hardness, strength, corrosion resistance, and heat resistance of the steel can be altered. For example, increasing the carbon content in steel can enhance its hardness and strength, while adding chromium can improve its resistance to corrosion. Overall, the composition of special steel plays a crucial role in determining its specific properties and suitability for various applications.

- Q: How does special steel perform in cryogenic applications?

- Special steel is known for its excellent performance in cryogenic applications. Cryogenic temperatures refer to extremely low temperatures below -150 degrees Celsius (-238 degrees Fahrenheit). In such conditions, regular steel tends to become brittle and lose its strength, making it unsuitable for use. However, special steel, also known as cryogenic steel or low-temperature steel, is specifically designed to withstand these extreme cold temperatures. One of the key properties of special steel is its ability to maintain its mechanical properties even at cryogenic temperatures. It retains its strength, toughness, and ductility, ensuring that it can withstand the stresses and strains imposed on it in cryogenic environments. This allows special steel to be used in various applications, such as cryogenic storage tanks, pipelines, and equipment in industries like aerospace, energy, and healthcare. Special steel also exhibits excellent resistance to brittle fracture at low temperatures. This is crucial, as brittle fractures can occur when materials become too brittle and fail under stress. The unique composition and processing of special steel help prevent this, ensuring the integrity and safety of components in cryogenic systems. Moreover, special steel has a low coefficient of thermal expansion, meaning it experiences minimal dimensional changes when exposed to temperature variations. This property is highly advantageous in cryogenic applications, as it helps maintain the stability and reliability of equipment and structures. In addition, special steel offers good corrosion resistance, which is essential in cryogenic environments where the presence of moisture and certain chemicals can accelerate corrosion processes. The resistance to corrosion ensures the longevity and durability of components, reducing maintenance and replacement costs. Overall, special steel is a preferred choice for cryogenic applications due to its ability to maintain mechanical properties, resistance to brittle fracture, low thermal expansion, and corrosion resistance. These properties make it a reliable and efficient material for use in cryogenic systems, providing the necessary strength and durability even in extremely low-temperature conditions.

- Q: How is special steel used in the medical manufacturing process?

- Special steel is used in the medical manufacturing process for a variety of applications, including the production of surgical instruments, implants, and medical devices. The unique properties of special steel, such as its corrosion resistance, biocompatibility, and strength, make it ideal for creating high-quality and durable medical products. Additionally, special steel can be easily sterilized, ensuring the safety and hygiene of medical equipment.

- Q: Can special steel be used in the medical field?

- Yes, the medical field utilizes special steel. Special steel alloys, including but not limited to stainless steel, find extensive application in medical and surgical instruments, implants, and equipment. Stainless steel is selected for its remarkable resistance to corrosion, exceptional strength, and enduring durability. It is commonly employed in surgical instruments like scalpels, forceps, and needles, as well as in orthopedic implants like bone screws and plates. Moreover, special steel alloys are employed in the fabrication of medical equipment such as MRI machines and X-ray tables, where high strength and magnetic properties are imperative. In summary, special steel plays a pivotal role in the medical field owing to its distinctive characteristics and capacity to meet stringent criteria for hygiene, safety, and dependability.

- Q: What are the different surface coatings applied to special steel?

- To enhance the performance and protect special steel from various environmental factors, there exist several surface coatings that can be applied. Some common options are as follows: 1. Galvanization: By applying a layer of zinc to the steel surface, galvanization provides exceptional corrosion resistance and prevents rusting. 2. Powder coating: This technique involves electrostatically spraying a dry powder onto the steel surface, which is then cured under heat. The result is a durable, decorative coating that offers excellent resistance to impact, abrasion, and corrosion. 3. Paint coating: Steel can be coated with a variety of paints, including epoxy, acrylic, polyurethane, and enamel. These coatings not only enhance the steel's appearance but also protect against corrosion and weathering. 4. Chrome plating: This process electroplates a thin layer of chromium onto the steel surface, providing excellent resistance to corrosion, wear, and abrasion. It is suitable for harsh environments. 5. Ceramic coating: Ceramic coatings can be applied using thermal spraying or plasma spraying methods. They offer high-temperature resistance, abrasion resistance, and excellent thermal insulation. As a result, they are used in industries such as aerospace and automotive. 6. Anodizing: Though commonly used for aluminum, anodizing can also be applied to certain special steel types. It involves creating an oxide layer on the steel surface through an electrochemical process. Anodizing enhances corrosion resistance and can be used for decorative purposes. These examples represent just a few of the available surface coatings for special steel. The selection of a coating depends on specific application requirements, such as corrosion resistance, wear resistance, temperature resistance, and aesthetic appearance.

- Q: How does special steel contribute to reducing product waste during manufacturing?

- Special steel contributes to reducing product waste during manufacturing by offering enhanced properties such as durability, strength, and corrosion resistance. This allows manufacturers to produce longer-lasting and more reliable products. By using special steel, companies can reduce the need for frequent replacements, repairs, or discarded products due to wear and tear. This not only minimizes material waste but also reduces the environmental impact associated with manufacturing processes.

Send your message to us

S35C Forged Alloy Steel Round Bars with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords