Alloy Steel SCM435 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy Steel SCM435 Round Bars

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Equivalent grades

| GB | DIN | AISI | JIS |

| 35CrMo | 1.7220 | 4135 | SCM345 |

Chemical Composition (%)

| C | Si | Mn | Cr | Mo | Ni | Cu | P | S |

| 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.80-1.00 | 0.15-0.25 | ≤0.030 | ≤0.030 | ≤0.035 | ≤0.035 |

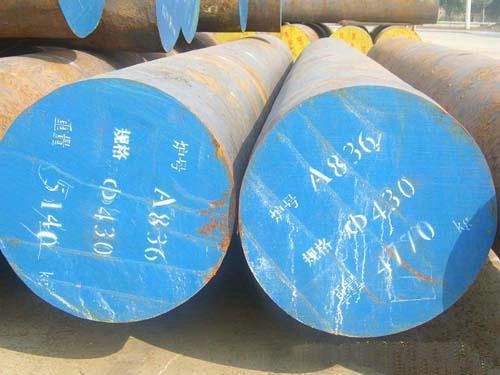

Products Show

Product Overviews

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, Mild steel shaft,ms bar | |

Material | ASTM | 1005, 1006, 1008, 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1055, 1060, 1065, 1070, 1080, 1084, 1016, 1022 |

DIN | Ck10, Ck15, Ck22, Ck25, Ck30, Ck35, Ck40,Ck45, Ck50, 30Mn4, 40Mn4 | |

BS | 040A04, 095M15, 045M10, 080A40, 045M10, 080M50 | |

JIS | S09CK, S9CK, S10C, S15C, S20C, S25C, S30C, S35C, S40C, S45C, S50C, S55C, S58C, SB45, S30C, S40C, S45C, S53C | |

Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| Section shape | Round, square, hexagonal, flat, angle | |

| Surface | Black painted, galvanized | |

Specifications | Round bar | Diameter: 4mm~1200mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width: 10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

Length | 2m, 4m, 5.8m, 6m, 11.8m, 12m or as required. | |

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the difference between hot rolled and cold drawn steel round bars?

- Hot rolled steel round bars are made by heating a billet or ingot of steel to a high temperature and then rolling it into the desired shape. This process results in a rougher surface finish and less precise dimensions compared to cold drawn steel round bars. Cold drawn steel round bars, on the other hand, are made by pulling a hot rolled bar through a die to achieve the desired shape and size. This process produces a smoother surface finish and more accurate dimensions. Overall, the main difference between hot rolled and cold drawn steel round bars lies in the manufacturing process and the resulting surface finish and dimensional accuracy.

- Q: How many positive and negative tolerances are allowed for round steel GB?

- Round steel is a solid strip of steel whose cross section is round. The specifications are expressed in millimeters of diameter, such as "50", which means a round bar of 50 millimeters in diameter. Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm. Among them, 5.5-25 mm small round bars are mostly supplied by straight strips. They are used as reinforcing bars, bolts and various mechanical parts. They are more than 25 millimeters of round steel. They are mainly used in the manufacture of mechanical parts or seamless steel tube billets

- Q: What is a steel round bar?

- A steel round bar, a lengthy metal rod with a circular shape, is usually made of strong and durable steel, an alloy composed mainly of iron and carbon. The round bar finds wide usage in industries like construction, manufacturing, and engineering, thanks to its flexibility and dependability. It is frequently employed as a structural element in buildings, as reinforcement or support in concrete structures, or as a part in machinery and equipment. The round shape enables effortless handling, machining, and welding procedures. Steel round bars are available in different diameters and lengths, and they can be further tailored or manufactured to suit particular project needs.

- Q: What are the different types of steel round bars used in the automotive engine components?

- There are several different types of steel round bars used in automotive engine components, each with their own specific properties and applications. 1. Carbon Steel Round Bars: These are the most common type of steel round bars used in automotive engine components. They are known for their high strength and durability, making them suitable for various applications such as crankshafts, connecting rods, and camshafts. Carbon steel round bars can withstand high levels of stress and are capable of withstanding extreme temperatures. 2. Alloy Steel Round Bars: Alloy steel round bars are made by adding different alloying elements such as chromium, nickel, and molybdenum to carbon steel. This enhances their strength, toughness, and wear resistance. Alloy steel round bars are commonly used in automotive engine components like gears, shafts, and bearings where high strength and resistance to wear and fatigue are required. 3. Stainless Steel Round Bars: Stainless steel round bars are highly corrosion-resistant and are often used in automotive engine components that come into contact with corrosive fluids or environments. They are commonly used in applications such as valves, pistons, and exhaust systems. 4. Tool Steel Round Bars: Tool steel round bars are characterized by their high hardness, resistance to abrasion, and excellent toughness. They are commonly used in automotive engine components that require cutting or shaping, such as cutting tools, dies, and punches. 5. High-Speed Steel Round Bars: High-speed steel round bars are designed to withstand high temperatures and maintain their hardness and cutting ability at high speeds. They are frequently used in automotive engine components like drills, milling cutters, and reamers. It's important to note that the specific type of steel round bar used in automotive engine components will depend on the specific application, performance requirements, and cost considerations. Automotive manufacturers carefully select the appropriate steel grade to ensure optimal performance and durability of engine components.

- Q: Can steel round bars be used in the manufacturing of valves?

- Yes, steel round bars can be used in the manufacturing of valves. Steel round bars are commonly used in valve manufacturing due to their high strength, durability, and corrosion resistance. The round bars can be machined and forged into various valve components such as stems, bodies, and discs. Steel round bars also provide excellent mechanical properties, ensuring the valves can withstand high pressure and temperature conditions. Additionally, steel round bars can be easily welded or threaded to connect different valve parts together. Overall, steel round bars are a reliable and popular material choice for valve manufacturing.

- Q: How are steel round bars used in the construction of stadiums and sports facilities?

- Due to their strength, durability, and versatility, steel round bars find wide application in the construction of stadiums and sports facilities. Typically made from carbon steel, these bars come in various diameters and lengths to cater to the specific requirements of each project. An important function of steel round bars in stadium construction is reinforcing concrete structures. They are commonly embedded within concrete columns, beams, and slabs to enhance their load-bearing capacity and overall structural integrity. The exceptional tensile strength of steel enables it to withstand heavy loads and provide crucial support for large seating areas, roofs, and other architectural elements. Moreover, steel round bars are utilized in the construction of stadium roofs and canopies. These structures demand a material that is both strong and lightweight, capable of spanning long distances without excessive reliance on support columns. Steel bars, when designed and installed properly, offer an optimal solution by providing the necessary strength while minimizing the number of support elements, thus allowing unobstructed views and spacious seating arrangements. In addition, steel round bars are commonly employed in the fabrication of stadium fences, guardrails, and handrails. These components are essential in ensuring the safety and security of spectators, preventing falls or accidents in elevated areas, and guiding the flow of people within the facility. The high tensile strength of steel makes it an ideal material for these applications, providing the necessary resistance against impact. To summarize, steel round bars play a crucial role in the construction of stadiums and sports facilities. Their strength, durability, and versatility make them the preferred choice for reinforcing concrete structures, constructing roofs and canopies, and fabricating safety components. By incorporating steel round bars, stadiums can be built to withstand heavy loads, offer unobstructed views, and ensure the safety of spectators, ultimately enhancing the overall experience for sports enthusiasts.

- Q: How do you determine the straightness of a steel round bar?

- To determine the straightness of a steel round bar, there are several methods that can be used. One common method is visual inspection, where the bar is carefully examined for any visible bends, twists, or deviations from a straight line. This can be done by placing the bar on a flat surface and checking for any gaps or unevenness between the surface and the bar. Another method is to use a straightedge or a precision ruler. By placing the straightedge or ruler along the length of the bar, any deviations from a straight line can be easily detected. This method allows for more precise measurements and can help identify even slight bends or curves. Measuring devices such as dial indicators or laser alignment tools can also be used to determine the straightness of a steel round bar. These devices provide more accurate measurements and can quantify the degree of straightness by providing numerical readings of any deviations from a straight line. It is important to note that the acceptable level of straightness may vary depending on the specific application or industry standards. In such cases, specific tolerances or guidelines may need to be followed to ensure that the steel round bar meets the required straightness criteria. Overall, determining the straightness of a steel round bar requires careful visual inspection and the use of appropriate measuring tools to ensure that it meets the necessary straightness standards for its intended use.

- Q: Excuse me, the difference between round steel, screw steel, steel, plate material, steel wire, hope professional answer

- The 2 plate and steel hot rolled steel plate, it is hard to know, the difference between rebar and rod easily screwed, clear, thread steel by chemical factory is a very deep rib.

- Q: The diameter of 20 solid round steel bend into a circle, what machine bending?

- Hydraulic steel bar cutting and bending machineThe hydraulic steel bar cutting and bending machine is a dual-purpose machine which uses hydraulic technology to cut and bend steel bars. It has high automation and convenient operation.Structure: hydraulic type steel bar cutting and bending machine mainly consists of hydraulic transmission system, cutting mechanism, stubborn mechanism, engine, airframe and so on.Working principle: an electric motor drives two sets of plunger hydraulic pumps, one group pushes off the piston, and the other drives the rotary hydraulic cylinder to drive the rotary working disc to rotate.Cut off the working principle of mechanism in cutting piston is arranged in the middle column and the center of the valve spring, in turn, due to the action of the spring, the middle hole make the center column left valve hydraulic cylinder, high pressure oil is also from the eccentric shaft road to tank. In the cut, a human powered piston, the center hole center column valve blocked the hydraulic cylinder, the plunger pump to the hydraulic cylinder through high pressure oil into the oil valve, high pressure to push the piston movement, the piston drives the cutter to cut tendons. At this point, the thrust of the pressure spring is greater than the pressure in the hydraulic cylinder, the valve will return to its original position, and the hydraulic oil will flow along the oil channel of the central oil hole back into the tank. The return stroke of the piston is achieved by the rebound force of the plate spring.

- Q: Can steel round bars be used in the shipbuilding industry?

- Yes, steel round bars can be used in the shipbuilding industry. They are commonly used for various applications such as structural components, supports, and reinforcement due to their strength, durability, and versatility.

Send your message to us

Alloy Steel SCM435 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords