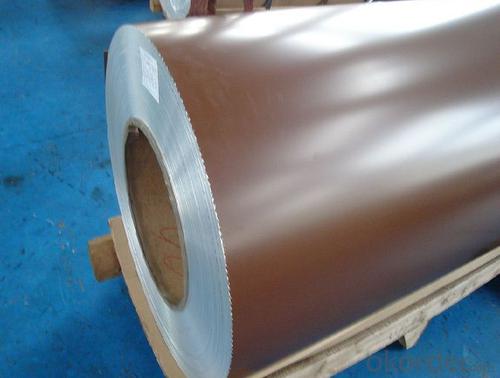

Rustic Red Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Aluminium Coil for Decoration

l Product Description

1 Building outer wall, curtain wallboard, airport, railway station, ect.

2 The old buildings renovation

3 Equipment unit, indoor compartment

4 Billboard, identification board, advertising signboard

5 Install the panel, show stand shelf inside

6 Industrial material protecting the car body of the old car

7 Other place that you want to use

Feature:

1 Light weight and easy to process

2 High peeling strength

3 Super weather resistance

4 Even coating and multiple colors

5 Excellent impact resistance

6 Excellent fireproof feature

7 Easy to maintain

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What are the different edge treatments available for aluminum coils?

- Aluminum coils offer a variety of edge treatments, each with its own benefits and uses. 1. Mill Finish: The aluminum coil remains as it is after manufacturing, without any additional treatment. This option is ideal for industrial or construction applications that prioritize functionality over aesthetics. 2. Trimmed Edge: The edges of the aluminum coil are carefully trimmed to remove sharp edges, ensuring safe handling and reducing the risk of injury during fabrication or installation. 3. Deburred Edge: Similar to the trimmed edge treatment, the deburred edge involves eliminating burrs and sharp edges from the coil's edges. This is important when the aluminum coil will come into contact with other materials or surfaces to prevent scratches or damage. 4. Rolled Edge: The edges of the aluminum coil are rolled to create a smooth, rounded edge. This not only enhances the coil's appearance but also provides additional protection against corrosion and damage. 5. Beveled Edge: An angled cut is made on the edges of the aluminum coil to achieve a sloping edge. This treatment is commonly used in architectural applications where a sleek and modern look is desired, and it also facilitates easier welding or joining of the coil. 6. Hemmed Edge: The edges of the aluminum coil are folded or bent to create a hem-like finish. This treatment adds strength and rigidity to the coil, making it suitable for applications that require durability or structural integrity. 7. Painted or Powder Coated Edge: The edges of the aluminum coil are painted or powder coated to match the color or finish of the rest of the coil. This is often done for applications where the coil's edges are visible, achieving a seamless and consistent appearance. Ultimately, the choice of edge treatment for aluminum coils depends on the specific needs of the application, considering both functionality and aesthetics.

- Q: What happened to the aluminum coil coming out of the annealing furnace?

- There is oil on the aluminum coil and the annealing time is too long.

- Q: How do aluminum coils contribute to sustainable construction?

- Aluminum coils contribute to sustainable construction through their lightweight nature, recyclability, and energy efficiency. The use of aluminum in construction significantly reduces the weight of structures, leading to less material consumption, lower transportation costs, and reduced energy requirements during construction. Additionally, aluminum is highly recyclable, allowing for the reuse of the material at the end of its life cycle, further reducing waste and environmental impact. Moreover, aluminum coils are known for their excellent thermal conductivity, enabling energy-efficient designs by improving insulation and reducing heating and cooling needs in buildings. Overall, aluminum coils play a crucial role in sustainable construction by promoting resource efficiency, waste reduction, and energy conservation.

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coil typically requires specialized tools to ensure safety and efficiency. Essential tools include a coil cutter for precise cutting, a coil car for easy transportation, and a decoiler for unrolling the coil. Additionally, protective gloves and safety glasses are crucial for personal protection. For more complex tasks, a shear machine or press brake may be necessary for shaping the aluminum. Always follow safety guidelines and use the appropriate tools for the job to prevent accidents and ensure quality work.</p>

- Q: What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- Go to an automotive parts store, like Pep Boys- they sell a gasket adhesive for rubber trim on cars that works very well- Also, there is an outstandingly strong spray adhesive called 3M-77 - buy it in the paint sections at Lowes( about $13.00 a can- but it is a big can!) Spray on the aluminum, spray on the rubber- let dry for about ten minutes and attach- Be careful- 77 is a one way adhesive- once it is stuck, no repositioning it- it's stuck for good! Do not wear latex or rubber gloves- they will stick, too- wear cheap cotton or jersey gloves while working with this kind of instant adhesive. BTW, be sure to clean the aluminum and rubber with solvent before applying the adhesive- any oil and the fix won't work.

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum has excellent thermal conductivity, making it an efficient choice for heat transfer applications in power generation equipment such as heat exchangers and condensers. Additionally, aluminum's lightweight nature and corrosion resistance make it a viable option for various power generation processes, including wind turbines and hydroelectric power plants.

- Q: What are the various categories of aluminum coils based on their characteristics and applications?

- <p>Aluminum coils are categorized based on their thickness, alloy composition, surface treatment, and temper. The main types include: 1) Thickness-based: thin gauge, medium gauge, and thick gauge coils. 2) Alloy composition: 1000 series (99% aluminum), 3000 series (aluminum-manganese), 5000 series (aluminum-magnesium), 6000 series (aluminum-silico-magnesium), and 7000 series (aluminum-zinc). 3) Surface treatment: mill finish, anodized, painted, and coated. 4) Temper: O (annealed), H (strain hardened), W (solution heat treated), and T (thermally treated to various strengths). Each type serves specific industries such as construction, automotive, packaging, and aerospace.</p>

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel for several reasons. Steel is a strong and durable material that can withstand the heavy loads and constant wear and tear of train traffic. It also has good heat resistance and can maintain its structural integrity under high temperatures, which is important for tracks that are exposed to friction and heat generated by moving trains. Aluminum, on the other hand, is a lighter metal with lower strength and poorer heat resistance compared to steel. While aluminum may be used in other components of railway infrastructure, such as electrical wires or certain parts of trains, it is not suitable for the production of railway tracks themselves.

- Q: What are the different types of aluminum coils?

- There are several different types of aluminum coils available, each with its own unique properties and uses. Some common types include: 1. Plain Aluminum Coils: These coils are typically made from pure aluminum and are used in a variety of applications, including packaging, construction, and automotive industries. 2. Embossed Aluminum Coils: These coils have a textured or patterned surface, which adds aesthetic appeal and can enhance the grip or provide anti-slip properties. They are commonly used in architectural designs, signage, and decorative applications. 3. Color Coated Aluminum Coils: These coils have a protective coating applied to the surface, providing enhanced durability, weather resistance, and aesthetic customization. They are often used in building facades, roofing, and cladding systems. 4. Anodized Aluminum Coils: Anodization is an electrochemical process that forms a layer of oxide on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized aluminum coils are commonly used in architectural applications, electronics, and automotive parts. 5. Pre-painted Aluminum Coils: These coils have a layer of paint applied to the surface, providing protection against weathering and adding color aesthetics. They are frequently used in the construction industry for roofing, siding, and insulation purposes. 6. Stucco Embossed Aluminum Coils: These coils have a raised pattern resembling stucco, which adds texture and enhances the strength of the aluminum. They are commonly used in refrigerators, air conditioners, and other appliances. 7. Clad Aluminum Coils: Clad aluminum coils consist of two or more layers of aluminum bonded together for enhanced strength, durability, or specific properties. They are used in various industries, such as aerospace, defense, and transportation. Overall, the choice of aluminum coil type depends on the specific application requirements, such as desired appearance, corrosion resistance, durability, and mechanical properties.

Send your message to us

Rustic Red Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords