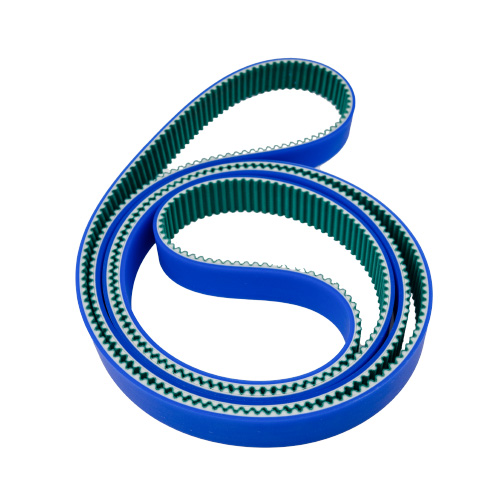

Heat Resistant Silicone Rubber Timing Belt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Silicone rubber timing belt is the silicone coated on the rubber timing belt, this technique is quite innovative in the world. Silicone rubber can withstand high temperatures without losing its physical properties, making it suitable for applications where heat is a concern. It is perfectly used for high-speed machine.

In China, Puteken is a major silicone rubber timing belt producer, offering customer with best silicone for timing cover with customized specification, meeting diverse industrial needs.

High Temperature Resistance: The base belt rubber and coating silicone both has the feature of heat resistance.

Wear Resistance: The silicone coating has higher wear resistance compared with rubber coating.

Non-sticky: The coated silicone has characteristic of non-sticky, it is very important in diaper and napkin production process.

High Friction

Brand Puteken Coating Silicone Color White/blue/gray Thickness 1.5-10mm Hardness 40 shore A Temperature -20℃-120℃ Features Wear resistance, anti-adhesion, high friction

If you are interested in silicone timing belt , welcome to search “Puteken” to know more about sponge conveyor belt. Puteken is your best choice for your market.

- Q: What are the main failure modes of belt drives?

- There are 2 main types: skidding and fatigue failureSkid: generally, when the force of transmission is greater than the sum of the friction between pulleys, overload, skid, transmission failure will occur.Fatigue failure: the belt cracks under the repeated action of stress, delamination, loosening, and fracture.

- Q: Excuse me, where is the rubber belt wholesale market in Toronto?

- This kind of thing is not a commonly used commodity, and is generally used by professional engineering companies. They usually order after-sales service through equipment vendors.

- Q: What is belt drive? What are the types and characteristics of belt drives?

- A: the belt drive is composed of a belt pulley (driven wheel) fixed on the driving shaft, a pulley (driven by a driven wheel) fixed on the driven shaft and a belt which is tightly sheathed on the wheelThe type of belt drive:The common driving types are flat belt drive, V belt drive, multi wedge belt drive and synchronous belt driveFlat belt transmission is the simplest structure in belt drive, which is suitable for the condition that the center distance is large, but it is not suitable for high speed transmission

- Q: What are the measures to prevent the slipping of the triangle belt?

- But maintenance triangle belt generally use special belt core, not elongation, maintenance free, the price is slightly expensive, but the overall calculation is better than using ordinary belt

- Q: Excessive loose of engine belt

- 4, the ignition time is too early or too late;;5, the shutter can not be fully opened;6, the mixture is too thin or too dense;7, the water tank outside dirty or internal scale serious, cause heat dissipation is not good, need to pass (clean) water tank or replace;8, fan clutch time is too late, or cooling fan does not work, fan rotation resistance is too large, the blade installed in reverse, blade damage, etc.;9, the electric fan performance is bad or no high speed;10, the combustion chamber has too many carbon deposits;11 、 the pump belt is too loose;12, three yuan catalytic problem;13, punch in the phenomenon of gas through the water;

- Q: What are the advantages and disadvantages of chain drive and synchronous belt pulley?

- The structure features: the cross section is rectangular, and the belt with a mask with isometric transverse teeth is used, and the synchronous belt wheel face is also made into a corresponding tooth shape.Transmission characteristics: the synchronous belt teeth and synchronous belt meshing between the teeth to drive, the two without relative slip, and make the circle speed synchronization, so called synchronous belt drive.

- Q: What are the failure modes of belt drives?

- Wear of working face of beltBecause of the elastic slip and slippage of the belt, the relative sliding between the belt and the pulley causes the working face of the belt to be worn out. Therefore, the design principle of belt drive is that the full capacity of the work should be avoided without slipping, and the transmission is required to have enough fatigue strength to ensure a certain service life. That is, under the condition of no skidding, the belt has a certain fatigue strength and life.

- Q: I bought a new treadmill and I don't know why there are so many black patches behind it

- There may be a relationship with the rotation of the factory running, some not polished corners

- Q: What is the phenomenon of belt drives for bicycles?

- The bicycle structure itself is light, and the use of the environment is very bad. The components to withstand dust vibration often need = = maintenance, so the chain than the drive belt is reliable and durable.I think so...

- Q: What are the types of transmission belts?

- 1, according to the relative position of the two shafts and the direction of the teeth, can be divided into the following types:<1> cylindrical gear drive;<2> bevel gear drive;<3> staggered helical gear drive.

Send your message to us

Heat Resistant Silicone Rubber Timing Belt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products