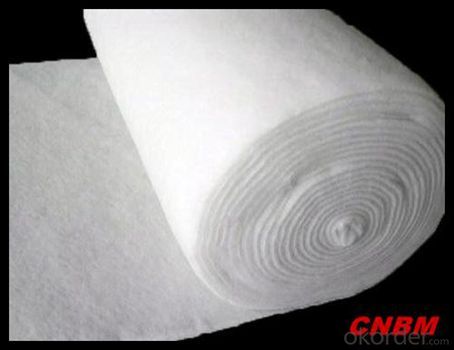

Rs580i Highist Nonwoven Geotextile Polyester & Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by differentequipment and technology to get different thickness. The main function is filtration, drainage, reinforcement. It has good impermeability and resistance to deformation

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Would like to know the product of the market

- Geotextile short wire geotextile, filament geotextile, polypropylene geotextile, the weight of 100g ~ 1000g per square meter range, different prices of different prices in a dollar to nine yuan range, according to the type of raw materials and specifications

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer numerous benefits in construction projects. Firstly, they provide effective soil stabilization by preventing erosion, reducing sedimentation, and enhancing soil strength. Secondly, they act as a barrier against weed growth, enhancing the aesthetics and longevity of the project. Additionally, geotextiles facilitate efficient drainage, preventing water accumulation and potential damage to structures. They also aid in separation and filtration, preventing the mixing of different materials and promoting the flow of water. Furthermore, geotextiles are cost-effective and easy to install, saving both time and labor. Overall, the use of geotextiles in construction projects improves durability, reduces maintenance needs, and ensures long-term sustainability.

- Q: Where are geotextiles used?

- Geotextiles are used in various applications such as construction, civil engineering, agriculture, and environmental projects. They are commonly used to reinforce soils, control erosion, separate materials, and provide filtration and drainage in roadways, retaining walls, landfills, dams, and other similar structures.

- Q: Can geotextiles be used in mine tailings management?

- Yes, geotextiles can be used in mine tailings management. Geotextiles are often employed in the construction of tailings dams and containment structures to provide reinforcement, filtration, and separation. They can help improve the stability and strength of the tailings containment system, prevent erosion and seepage, and facilitate water drainage.

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Is still using such a backward technology?

- Q: What are the factors to consider when selecting geotextiles for a specific project?

- When selecting geotextiles for a specific project, there are several factors to consider. These include the project requirements and objectives, the type and intensity of loads the geotextiles will be subjected to, the site conditions and soil characteristics, the desired lifespan of the geotextiles, and the environmental considerations. Additionally, factors such as the cost, availability, and compatibility with other materials should also be taken into account.

- Q: Why is the roadbed geotextile

- Put the geotextile for water treatment

- Q: Filter geotextile performance ~ main function ~

- Filter geotextile performance ~ main function ~

- Q: Can geotextiles be used in the construction of stormwater ponds?

- Yes, geotextiles can be used in the construction of stormwater ponds. Geotextiles are commonly employed in stormwater management systems to enhance filtration, separation, and erosion control. They can be used as a lining material to prevent soil erosion and provide stability to the pond. Additionally, geotextiles can help with sediment control, maintaining water quality, and supporting vegetation growth in stormwater ponds.

Send your message to us

Rs580i Highist Nonwoven Geotextile Polyester & Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords