Packaging & Delivery

| Packaging Details: | With bundles and load in containers or by bulk shipment. |

|---|---|

| Delivery Detail: | 30-45 days according to the contract |

Specifications

1.Size:15*15mm-400*400mm2.W.T:0.5-12mm

3.Certification:ISO9001,CE

4.Standard:GB, ASTM.BS1387

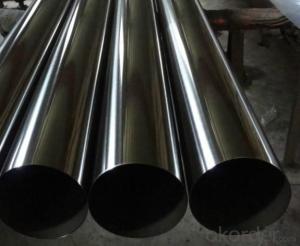

galvanized steel pipe

1.ERW galvanized steel tubes

2.OD: 10.3-219mm

3.W.T:0.6-10mm

4.Certificate:ISO 9001-2008

5.Output per month:20000 tons

ERW galvanized steel tubes | |||

O.D | O.D tolerance | W.T | Thickness Tolerance |

19--219MM | ±0.03 | 1.0--10MM | ±0.03 |

Length | 2--12M , according to customers' requirements | ||

Zinc coating | 275--350g/m2 | ||

International Standard | ISO 9001;2008 | ||

Standard | ASTM A 53 / BS 1387-1985 | ||

Material | Q195/Q215/Q235/Q345 | ||

Product Category : | Metallurgy, Mineral & Energy | ||

Technique: | Welded | ||

Packing | In bundles or according to customers' requirements | ||

Usage | 1.For low pressure liquid delivery such as water , gas and oil 2.For construction , e.g building greenhouse | ||

Main market: | Middle east, Africa, North and South America, East and West Europe, South and southeast Asia,Australia | ||

Place of Origin | China | ||

HS code: | 7306309000 | ||

Productivity | 20000Ton/Month | ||

Processing technology available: | Threading , coupling and with plastic caps protected | ||

Remarks | 1) Payment term : T/T 2) Trade Terms : FOB / CFR /CIF 3) Minimum quantity of order : 25 MT (25,000KGS) 4) Delivery period : 10 to 30 Days . | ||