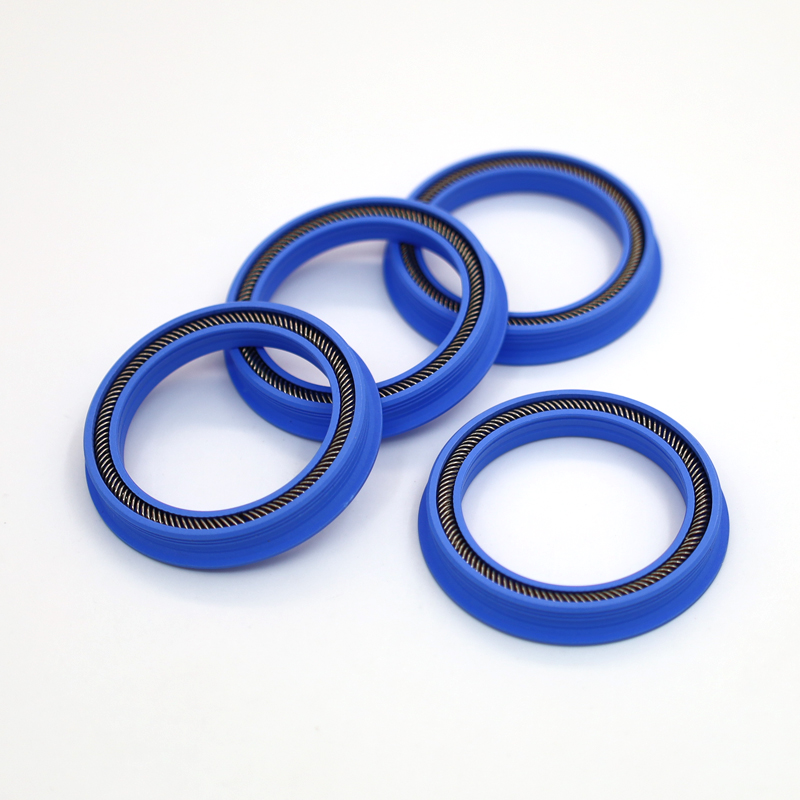

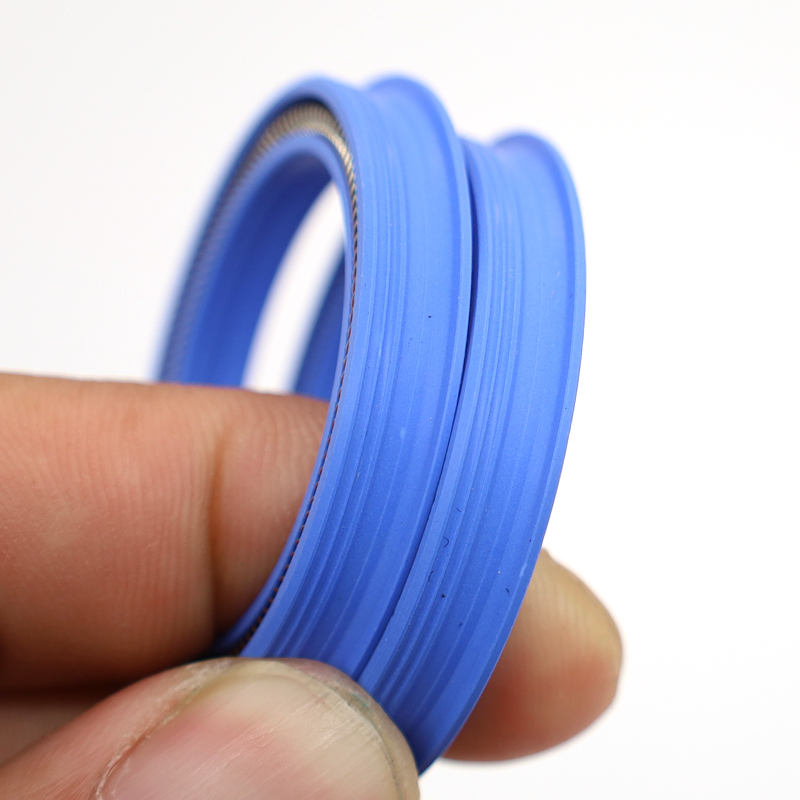

Rotary Spring Seal PTFE seals add Glass Fiber polytetrafluoroethylene X inclined spring Customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 LOT

- Supply Capability:

- 20000 LOT/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

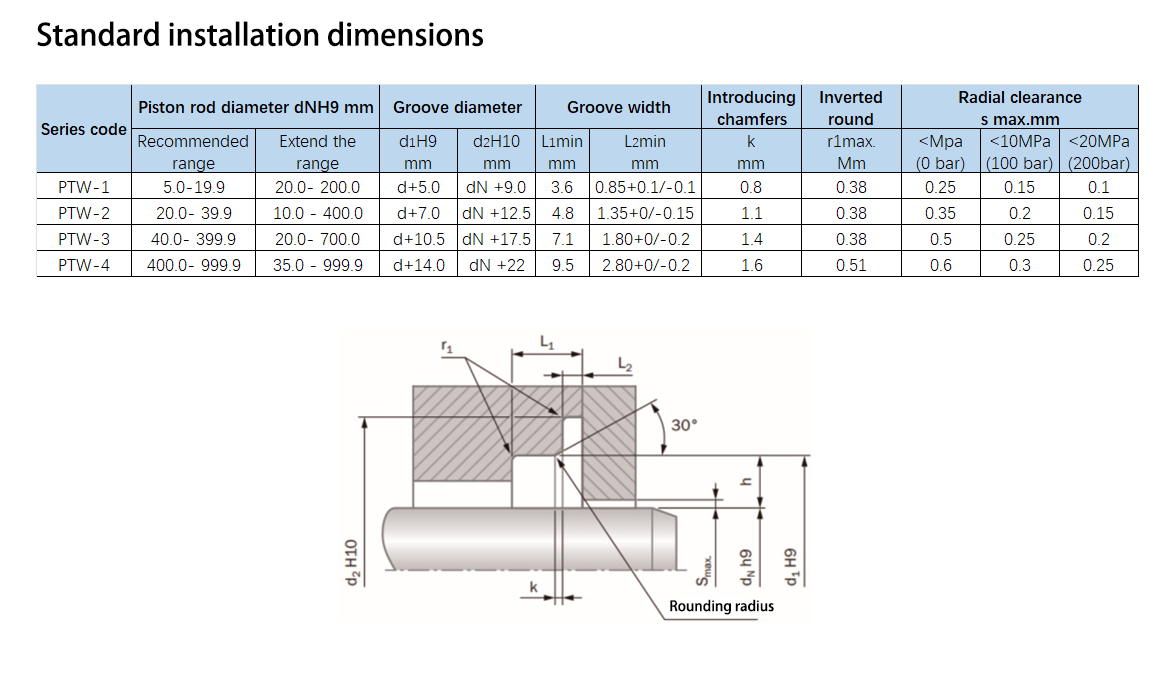

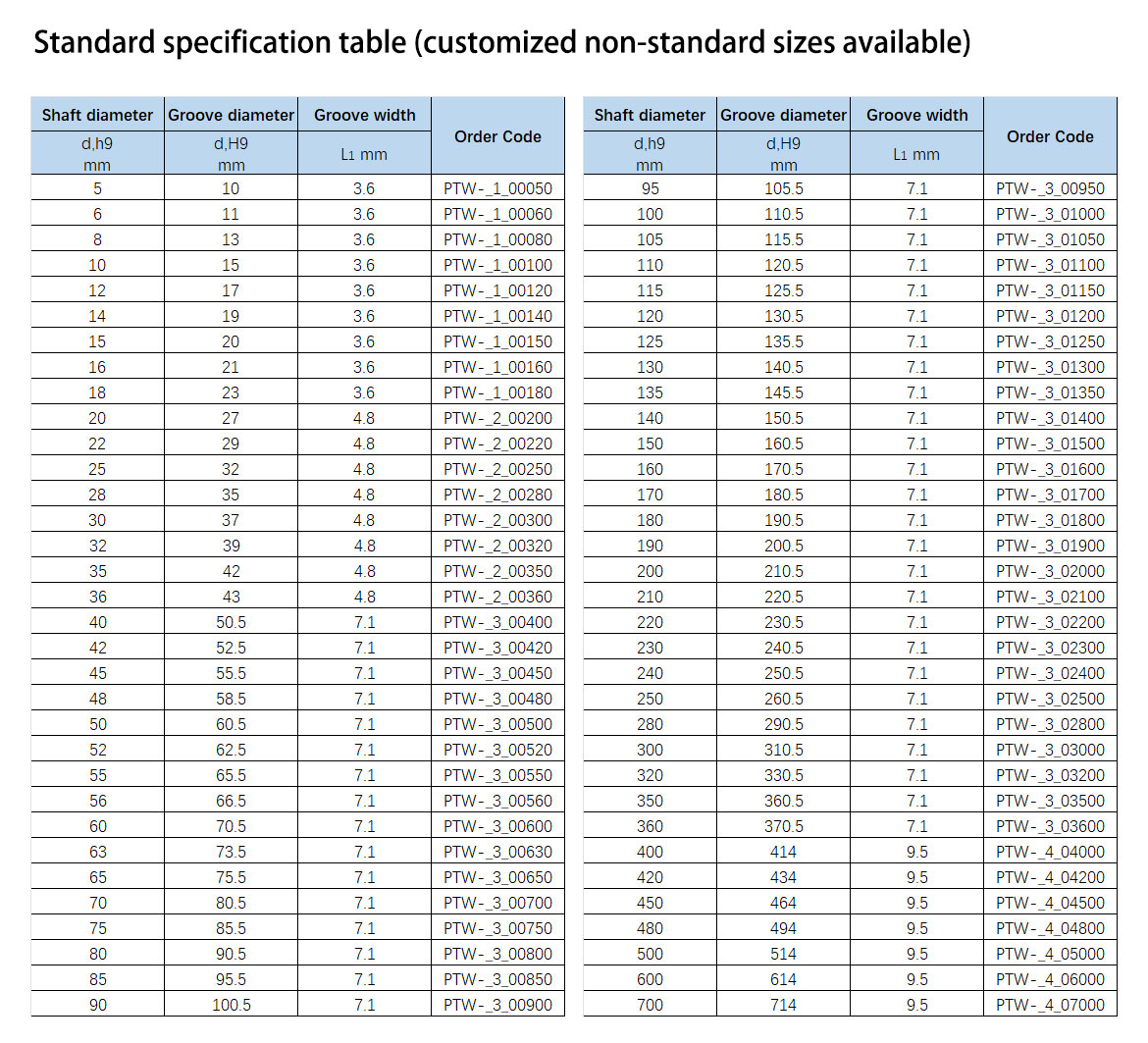

Specification

If you need a large quantity of products, different materials or sizes, please contact customer service.

High quality factory, focus on high-end seals! Fast shipping!

Use and performance

PTFE (Poly tetrafluoroethylene, abbreviated as PTFE), commonly known as "Plastic King", is a high molecular polymer made by polymerization of tetrafluoroethylene as a monomer. White waxy, translucent, excellent heat and cold resistance, can be used for a long time at -180~260ºC. This material has the characteristics of anti-acid, anti-alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its coefficient of friction is extremely low, so it can be used not only for lubrication, but also as an ideal coating for the inner layer of water pipes that are easy to clean.

The high-performance PTFE materials we provide can be used in the production and processing of various seals.

- Q: What problems need to pay attention to when inflating the pipe?

- Rubber pipeline plugging bag should keep the inner pressure of the gasbag is uniform when inflated, inflated slowly rising inflation, observe the pressure gauge without change, such as pressure gauge shows rapid rise in inflation is too fast, the inflation rate should slow down, stop valve will tighten slightly, reduce the inlet velocity, or the speed is too fast, faster than pressure is likely to break into the rubber balloon. - Zhang

- Q: What's the difference between silicone products and rubber products?

- The materials used are different: in other industries, the rubber products used are nitrile rubber, and the silica gel products are made of silica gel.

- Q: Does antirust oil affect rubber?

- Antirust oil on rubber must have some influence, and a variety of anti rust oil, you can choose corrosive minimum rust preventive oil,,

- Q: What are the uses of rubber oil?

- Application: mainly used as rubber softener. The effect of carbon black rubber products: rubber materials have good dispersing effect of softening rubber, increase the viscosity, make the rubber soft and smooth, and can improve the anti corrosion performance of coke products cold, another of the thiazole accelerator can increase the activation effect of complexing agent

- Q: Can PVC blend with rubber?

- PVC is a high polar polymer, so it has good compatibility with polar rubber,

- Q: Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Usually smoked rubber, crepe, dry glue, glue... Etc.. The dry glue without smoke and natural rubber, color to dry shallow, suitable for light and color products

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q: How long does the rubber last?

- In addition, aging has ozone aging, weather aging, heat aging and so on. Ding Qing rubber is not resistant to ozone, the time is not long, it will appear aging.

- Q: What is the rubber composition of sole?

- The sole of high pressure polyethylene and rubber flavor, rubber and plastic used together.Student: Rubber soled heavy, expensive, not resistant to oil, heat. Variable color.

- Q: Which kind of rubber has the best wear resistance?

- In addition, it also has good water resistance, air tightness and excellent adhesive properties. Widely used in various kinds of oil resistant rubber, oil resistant gasket, gasket, sleeve, flexible packaging, soft hose, rubber roller, rubber cable printing and dyeing materials, become the indispensable elastic material in automobile, aviation, petroleum, copying and other industries.NBR has excellent oil resistance, and its oil resistance is second only to that of polysulfide rubber and fluorine rubber, and it has the characteristics of wear resistance and air tightness. Ding Qing rubber is the disadvantage of ozone and aromatic, halogenated hydrocarbons, ketones and esters solvents, it is not suitable for insulation.

Send your message to us

Rotary Spring Seal PTFE seals add Glass Fiber polytetrafluoroethylene X inclined spring Customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 LOT

- Supply Capability:

- 20000 LOT/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords