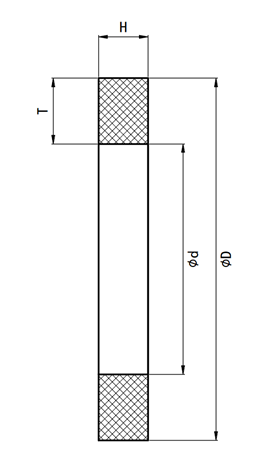

Polytetrafluoroethylene add glass fibre add oxide PTFE gaskets liner Shim Spacer Pads customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Material:

ptfe add glass fibre add oxide

If you need a large quantity of products, different materials or sizes, please contact customer service.

High quality factory, focus on high-end seals! Fast shipping!

A gasket is a material or combination of materials clamped between two separate joints (flanges) and serves to maintain a seal between the two joints for a predetermined service life. The gasket must be able to seal the joint surfaces and ensure that the sealing medium is impermeable and non-corrosive, and can withstand temperature and pressure, etc.

- Q: Which is better waterproof performance, neoprene or silica gel?

- Silicone rubber (Silicone, rubber), sub heat vulcanizing (high temperature vulcanized silica gel HTV), room temperature vulcanized (RTV), in which room temperature vulcanization type and polycondensation reaction type and additive reaction type.

- Q: What about the Poisson's ratio and modulus of elasticity of three yuan ethylene propylene rubber (EPDM)?

- Three yuan ethylene propylene rubber is ethylene, propylene and non conjugated diene three yuan copolymer, began commercial production in 1963. The consumption of the whole world is 800 thousand tons every year. The most important feature of EPDM is its superior oxidation resistance, ozone resistance and corrosion resistance. Because three yuan ethylene propylene rubber belongs to polyolefin family, it has excellent curing property. Of all rubbers, EPDM has the lowest specific gravity. It absorbs large amounts of fillers and oils and has little effect on properties. Therefore, rubber compounds with low cost can be made.

- Q: What kind of rubber coated aluminum alloy (metal) better

- White Silicone, or at cyanide rubber, you have to brush the surface of metal binder, general is muruk we do, rubber products, these things often encounter

- Q: How to make mobile phone rubber coat non stick ash?

- Stained with ash is not terrible, with a period of time you can use clean water with a small amount of detergent, wash it; if the stain is very serious, you can use alcohol wipe, and then clean with water.

- Q: Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The main factors affecting the tensile strength of rubber are: the main valence bond, intermolecular force and polymer chain flexibility of macromolecular chains. The relationship between tensile strength and structure of rubber: the intermolecular forces are large, such as polarity and rigid groups;

- Q: What's wrong with rubber whitening?

- White: may refer to spray frost (dissolved in more than rubber, drugs in rubber migration to the rubber surface), 1 reasons, excessive drug formulation; 2, sulfur is not complete, the two plus sulfur solution (130 - to 1 hour);It may be a white filler in rubber, so there's no way out. It's only the formula;

- Q: Can the rubber surface be painted with paint?

- Rubber surface of the original jet printing pattern, etc., how to remove clean, and does not affect the appearance and rubber layer: the way is solvent oil!

- Q: PVC conveyor belts and rubber belts differ from each other in their respective advantages

- Rubber belts are widely used in conveying equipment, but do you know that proper vulcanization of rubber can maintain high elasticity of rubber and make rubber of a certain strength?. At the same time, in order to increase product hardness, strength, wear resistance and tear resistance, while adding inert filler in the process (such as Zinc Oxide, clay, chalk and barite etc.) and reinforcing filler (such as carbon black), which helps to improve the quality of the conveyor belt.

- Q: Is there any poison in the processing and testing of rubber products? What about the salary?

- With some raw materials are generally low in rubber products, such as sulfur, amine antioxidant, lead salt, nickel salt what.In addition, when processing or testing, if there is temperature, pay attention to good protection.As far as salaries are concerned, generally 2k-3k, of course, there is a difference between local manufacturers.

Send your message to us

Polytetrafluoroethylene add glass fibre add oxide PTFE gaskets liner Shim Spacer Pads customized

- Loading Port:

- SHENZHEN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords