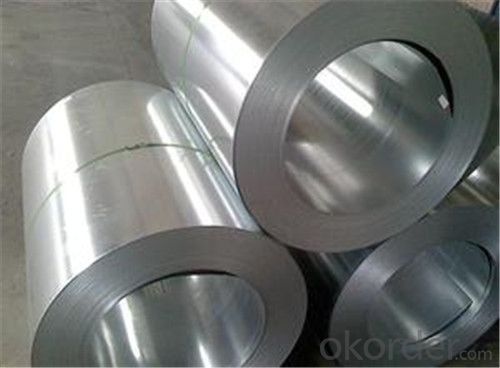

Rolled Steel Coil / Sheet / Plate SPCC in CNBM from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Characteristic:

Quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many rocessing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing

Details:

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

Images:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q: What is the diffrent Aluminized steel Type 1. stainless steel 409 430?

- Stainless steel 400 Series—ferritic and martensitic chromium alloys Type 409—cheapest type; used for automobile exhausts; ferritic (iron/chromium only) Type 430—decorative, e.g., for automotive trim; ferritic. Good formability, but with reduced temperature and corrosion resistance. Today, almost all bulk metal materials that are referred to loosely as aluminium, are actually alloys. For example, the common aluminium foils are alloys of 92% to 99% aluminium. Aluminized steel Type 1: 1xx.x series are minimum 99% aluminium

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability using a variety of methods to ensure their suitability for various applications. One common inspection method is the 3-point bend test, where the coil is subjected to a bending force at three specific points along its length. This test helps determine the coil's resistance to bending without fracturing or breaking. During the 3-point bend test, the coil is placed on a support system with two fixed points and one movable point. A force is then applied to the movable point, causing the coil to bend. The amount of force required to achieve a specific level of bending is measured and compared against acceptable standards. Another method used for inspecting steel coils is the mandrel bend test. In this test, a mandrel of a specific diameter is inserted into the coil and bent to a specified angle. The coil is then examined for any signs of cracking or deformation. This test helps determine the coil's flexibility and ability to withstand bending without damage. Visual inspection is also an important part of the inspection process. Trained inspectors visually examine the coil for any visible defects such as cracks, deformations, or irregularities. They also check for proper coil dimensions and uniformity throughout. In addition to these methods, non-destructive testing techniques like ultrasonic testing or magnetic particle inspection may be used to detect any internal defects or flaws that may affect the bendability of the coil. Overall, a combination of mechanical testing, visual inspection, and non-destructive testing methods are employed to ensure that steel coils meet the required bendability standards. These inspections help ensure the quality and reliability of the steel coils for various industries where bendability is a critical factor.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials by being fed into a roll-forming machine, which shapes the coils into the desired profile for the roofing panel. The coils are then cut to the appropriate length, coated with protective finishes, and formed into individual roofing panels that are ready to be installed on buildings.

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils used in the agricultural structure industry can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in this industry range from 0.5mm to 3mm in thickness, and from 600mm to 1500mm in width. The length of the coils can also vary, but typically ranges from 1000mm to 3000mm. These dimensions allow for flexibility in the construction of agricultural structures such as barns, sheds, and storage facilities, while providing sufficient strength and durability. It is important to note that specific dimensions may vary depending on the manufacturer and the specific needs of the agricultural project.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- Iron ore is just a rock -- in fact it would probably be hard to tell iron ore from a piece you found lying out in your backyard. It's what mines produce, and it needs to be burned to separate it into its different elements. Iron is an element. It is the purest form of the metal. Steel is mostly iron, but it is not pure iron. To make steel you must burn coke (another kind of rock) along with the iron ore. The coke adds carbon to the iron, producing steel which is stronger than pure iron.

- Q: How do steel coil manufacturers handle customer complaints?

- Steel coil manufacturers handle customer complaints by first listening to the customer's concerns and understanding the nature of the complaint. They then investigate the issue thoroughly, often by inspecting the product or reviewing production records. Once the cause of the complaint is determined, they take appropriate actions such as offering replacements, refunds, or repairs. They prioritize open communication with the customer, ensuring that their concerns are addressed promptly and professionally. Additionally, manufacturers may use customer feedback to improve their processes and prevent similar issues in the future.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Under certain conditions, even stainless steel will rust. They include: Exposure to some noble metals (copper/silver) in a corrosive atmosphere - and why stainless must be separated from silver or silver plate in a dishwasher. Stainless steel will pit if touching silver as many DW detergents are rich in chlorine. Under some conditions, and depending on your skin chemistry, if you wear a copper bracelet on the same arm as the watch, the surface of the watch will pit. If you commonly are exposed to some kinds of welding fluxes, if you are exposed to water with high salt concentration and you do not rinse off the watch after exposure, that can pit the surface. Stainless Steel is no more than corrosion-resistant, not corrosion-proof. Most of the time under most conditions, it is fine. But not all of the time under every condition. As it happens, what affects SS the most is any kind of electrolysis due to galvanic action involving halogen salts.

- Q: for my engineering project I have been asked to design a method of suspending a TV of weight 14Kg from a gantry, the TV must be 5m below the gantry. My team have decided to use as a suspension method a steel cylinder of outer diameter of 10cm and an inner diameter of 8, however we now need to work out both the max stress and strain and the actual stress and strain. and help would be useful

- the area of the cylinder bypass area is extensive actual its 28.26 cm^2 so if the wieght is 14 which ability the metallic consists of .5 kg/cm2 , which isn't something we enable metallic the gentle one carry as much as a million.4 t/cm2 that's 1400 kg no longer 0.5 , so dont worry urself approximately deflection....

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

Send your message to us

Rolled Steel Coil / Sheet / Plate SPCC in CNBM from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords