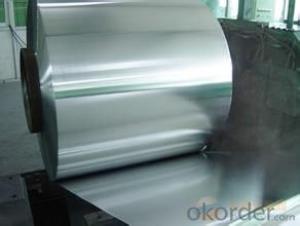

Cold Rolled Steel coil / Sheet / plate -SPCC from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Advantage:

1. High Quality SurfaceFinish

2. High Dimensional Precision

3. Excellent mechanicalproperty

Images:

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- In order to prevent rusting in the process of storage or transportation of steel roll, steel mills generally take the following packing: inner gas antirust paper wrapped with tape wrapped in plastic film sealing, intermediate, involute cardboard seal lining, cardboard corner, with iron and steel outer package corner protector, strapping fixed. If the inner package seal, so the steel coil is sank into the water, will not rust out.

- Q: How is the thickness of a steel coil measured?

- The thickness of a steel coil is typically measured using a device called a thickness gauge or micrometer. This tool consists of a calibrated mechanical or digital system that measures the distance between two opposing surfaces of the steel coil. By placing the gauge on the coil and applying pressure, the thickness can be accurately determined.

- Q: How are steel coils used in the shipbuilding industry?

- Steel coils are used in the shipbuilding industry primarily for the construction of ship hulls, decks, and other structural components. These coils are typically processed and shaped into plates, beams, and other forms to provide strength and stability to the ship's structure. The high tensile strength and durability of steel make it an ideal material for shipbuilding, ensuring the vessel's ability to withstand harsh marine environments and heavy loads.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- The difference in stainless steel cookware is the amount of different metals used when making them. 18-10 is the best combination. I have Tramontina SS pots and pans and love them. Nice heavy bottoms that evenly heat. Getting used to cooking with stainless is a bit difficult. You need to start with high heat and then turn it down when you add ingredients. This assists in food not sticking.

- Q: Can steel coils be coated with noise-reducing materials?

- Yes, steel coils can be coated with noise-reducing materials. These materials, such as rubber or polymer coatings, are designed to dampen vibrations and reduce noise generated during steel coil movement or processing. Coating steel coils with noise-reducing materials helps minimize noise pollution in various industrial applications.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers as they are shaped and formed into the required structural components, such as beams and brackets. These coils are processed through rolling mills to obtain the desired thickness and shape, ensuring the strength and durability of the towers. The steel coils provide the necessary strength and structural integrity to support the weight of the transmission lines, withstand environmental conditions, and ensure reliable power transmission.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Some Blazer/CCI loaded ammo comes with aluminum casings, it is easy to tell because they have a very dull finish compared to the nickel. These cases are not safe to reload. There is also Wolf brand from Russia that has a steel casing, it looks laqured and it may or may not be able to be reloaded.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as the core material for winding wire around. The coils provide a stable structure, allowing the wire to be tightly wound and creating the necessary resistance for regulating electric current flow.

- Q: Explain why a steel nail sinks but a steel ship floats.

- A steel nail is much denser than the water. That means that it weighs more than an equivalent volume of water. Therefore, the buoyancy is never going to be enough to hold it up. Whether it is a big steel nail or a small one, it will always be too dense for the water to support it. Because of its shape, a steel ship is not as dense as water. It is not made out of a solid block of steel. Instead, the hull is built of thin plates of steel enclosing an open space. A steel ship is sort of like an empty cup. Although its sides are hard and dense, it holds a lot of air in the middle. Since air weighs almost nothing, it lowers the overall density of the ship to a point where its buoyancy exceeds its weight, and the ship floats. Think of it as you trying to sink a balloon.

- Q: I'm getting my nose pierced, meaning that i have to keep the piercing in for a prolonged time. i've always had reactions when wearing sterling silver or fake earrings (i dont know what types of metal they were) after wearing it overnight. Will I get a reaction on my nose piercing if the stud is surgical steel?

- The chances of a reaction from the stud is minimal. Surgical steel is an alloy specifically designed to make sterile safe surgical equipment. Often made with titanium or nickel, surgical steel is highly reactive and forms an oxidized layer when made. This layer creates a stable surface. The titanium and nickel are both very hard and resistant to scratches which make for easy sterilization. This will help keep your piercing clean. Be sure to follow the directions you receive when you get your piercing and keep it clean.

Send your message to us

Cold Rolled Steel coil / Sheet / plate -SPCC from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords