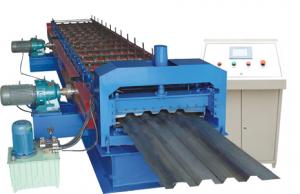

Roll Forming Machinery -Sandwich panelPRL-6-SA3

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

We can designthe line to make different kinds of panels in appearance, for wall panel androofing panel with various joint designs.

Sandwichpanel, as a new building material,shows excellent performance oninsulation.

It is takingthe place of brick to be a main material for building now.

High speedslitting and cut to length can cut steel with thickness from 1mmto 16mm, if noneed slitting thickness up to 30mm.

Processing flow is as following:

Carry coil→loadcoil→de-coiling(pressingguide +opener)→entry、roughlevel→cutting→transition→guide→slitting (waste winding) →loopingstorage→pre-separating, damping→recoiling→packing→discharging→guide→leveling→fix size (end platefeeding)→cutting→discharging

Technical Data:

1. TheManufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjustspeed)

2. TheThickness Of Sandwich Panel:30-200mm

3. TheThickness Of Steel : 0.4-0.8mm

4. TheLength Of The Production Line : about 120 meters

5. TheTotal Power Of The Production Line : 350 KW

6. TheLength Of The Double Belt Conveyer : 24m

- Q: Classification of sandwich panels

- Three polyester sandwich panel, or PIR sandwich panel;Phenolic sandwich panel, or PF sandwich panel;Rock wool sandwich board, or RW sandwich panel.Foam metal sandwich panel

- Q: How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- The utility model has the characteristics of light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire prevention, rainproof, long service life, maintenance free, etc., and has been widely popularized and applied.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- You don't know where is the statistics, color steel production line really the most private owner, but you do not have with Hebei Botou and Xinji the two production base, Shanghai original equipment really good, but along with the market competition and their quality is declining, which is now not to say, mainly to see their weight, the other is secondary, Beijing have never heard of the production of steel machinery.

- Q: How is the sandwich plate synthesized?

- The finished products of the sandwich panel are easy to install, light and efficient. The filling system also uses the closed bubble molecule structure to prevent the condensation of water vapor.

- Q: Can the sandwich board adhere to the plaster line?

- First brush on white latex (polyvinyl acetate emulsion), and then self tapping nails will be fixed on the wood board gypsum board, silk nail head must be slightly concave into the gypsum board, so as not to destroy the plaster board surface of the layer of paper for the most appropriate

- Q: Rock wool, color steel sandwich plate production line where good?

- Jizhong Machinery Manufacturing Co., Ltd. has won the title of state-level high-tech enterprises, and has been recognized by the Ministry of Commerce as a designated equipment export manufacturer.

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- The problems in forming of pressing sheet. It may be caused by the bending residual stress of the plate during forming;

- Q: What does color steel sandwich board mean?

- Can be called composite board and rock wool board: it is double deck color steel, sandwiched between foam or rock wool, the upper layer is a color panel.

Send your message to us

Roll Forming Machinery -Sandwich panelPRL-6-SA3

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches