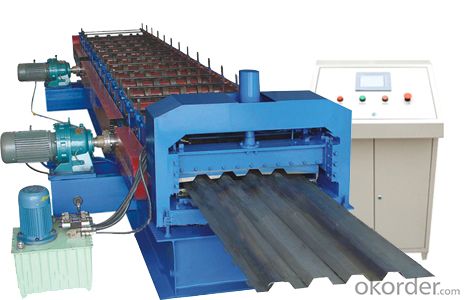

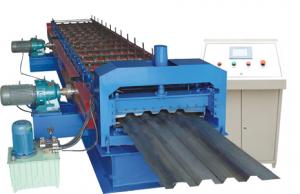

High Quality Sandwich panel Roll Forming Machinery -PRL-7-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Sandwich panel Roll Forming Machinery -PRL-7-SA

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

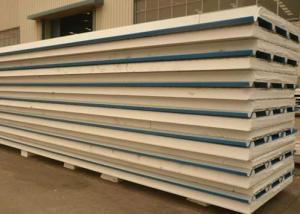

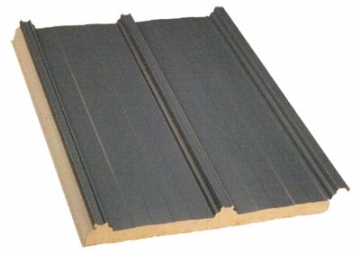

Sandwich panel, as a new building material,shows excellent performance on insulation.

It is taking the place of brick to be a main material for building now.

High speed slitting and cut to length can cut steel with thickness from 1mmto 16mm, if no need slitting thickness up to 30mm.

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

Carry coil→load coil→de-coiling(pressing guide +opener)→entry、rough level→cutting→transition→guide→slitting (waste winding) →looping storage→pre-separating, damping→recoiling →packing→discharging→guide→leveling→fix size (end plate feeding)→cutting→discharging

- Q: Classification of sandwich panels

- Three polyester sandwich panel, or PIR sandwich panel;Phenolic sandwich panel, or PF sandwich panel;Rock wool sandwich board, or RW sandwich panel.Foam metal sandwich panel

- Q: Characteristics of sandwich panels

- Fireproof, color steel composite core board of the surface material and insulation material for non flammable or refractory material, can meet the fire code requirements.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- You don't know where is the statistics, color steel production line really the most private owner, but you do not have with Hebei Botou and Xinji the two production base, Shanghai original equipment really good, but along with the market competition and their quality is declining, which is now not to say, mainly to see their weight, the other is secondary, Beijing have never heard of the production of steel machinery.

- Q: How is the sandwich plate synthesized?

- The finished products of the sandwich panel are easy to install, light and efficient. The filling system also uses the closed bubble molecule structure to prevent the condensation of water vapor.

- Q: What is the color steel sandwich board?

- Color steel sandwich plate refers to the color steel clip some insulation board, mainly with some movable board room use.

- Q: Can the sandwich board adhere to the plaster line?

- Carpentry board is big core board, it is solid wood to spell, gesso board is gesso to make, outside a layer of kraft paper, two material is different. Wood board is commonly used materials currently Jiezhuang, generally used as lining making furniture, door, use is very extensive. Gypsum board is generally used for ceiling, television, wall and so on, but it needs carpentry rendering.

- Q: What's the difference between sandwich board and composite board?

- The metal materials industry in composite plate refers to a layer of metal plate coated with another metal plate, in order to use does not reduce the effect (corrosion resistance and mechanical strength) under the premise of saving resources, reduce the cost effect.

- Q: Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- Foam sandwich board, beautiful shape, bright color, good overall effect, it sets the bearing, thermal insulation, waterproof in one, and no two decoration, is a widely used, especially in the temporary facilities for construction sites such as office, warehouse, wall and so on, but also the modern construction site civilization construction.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Clean room decoration requirements are very special, do not allow the use of decorative lines and other special protrusions, Yin, Yang Kok should be made of arc, wall and ceiling should be smooth, smooth, no seams or seams tight.

Send your message to us

High Quality Sandwich panel Roll Forming Machinery -PRL-7-SA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords