Multifunctional PU Sandwich Panel Continuous Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 sets per year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Multifunctional PU sandwich panel continuous line

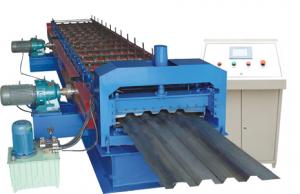

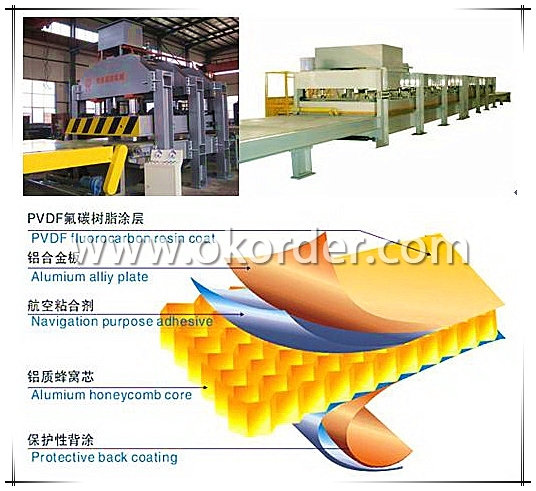

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

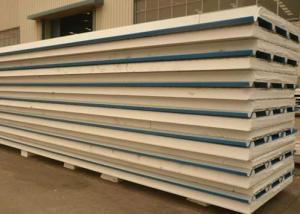

Sandwich panel, as a new building material shows excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Technical Data of Multifunctional PU sandwich panel continuous line

1. The Manufacture Speed of Sandwich Panel: 8.6m/min( frequency conversion to adjust speed)

2. The Thickness of Sandwich Panel: 30-200mm

3. The Thickness of Steel: 0.4-0.8mm

4. The Length of the Production Line: about 120 meters

5. The Total Power of the Production Line: 350 KW

6. The Length of the Double Belt Conveyer: 24m

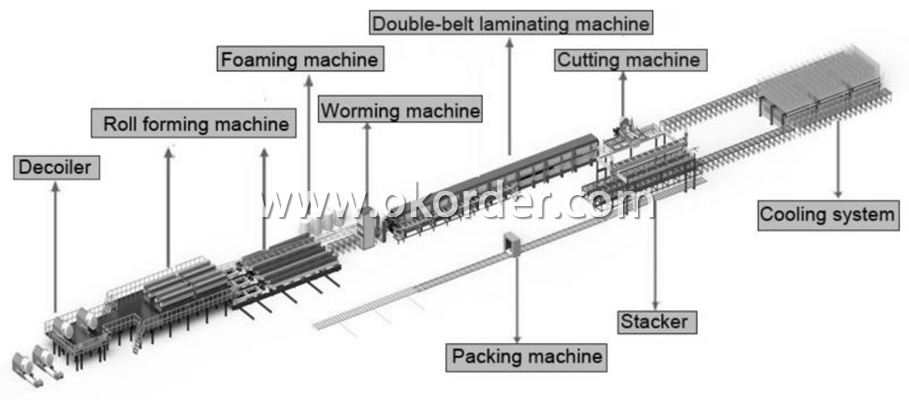

PU Sandwich Panel Continuous Line

1 The equipment is accurate and durable.

2 The tape mechanism has a tension control device, enabling the overlay material evenly into the mould, to make sure the piece has a smooth surface.

3 The side block and adhesive tape recirculation device can guarantee the sealing of the piece and its demolding.

4 The double-crawler laminating system is of pressure proof, and can achieve a continuously automatic production and limit the foaming material within the mould, ensuring a stable feature in product size.

5 The following conveying and cutting systems can work simultaneously to produce plates of any length.

Working flow of Multifunctional PU sandwich panel continuous line:

Features of Multifunctional PU sandwich panel continuous line:

1. Beautiful appearance, low noise, high efficiency

2. Multiple functions: could produce 4 kinds of panel, wall pane, roof panel, cold room panel, and garage door panel.

3. The line employs advanced PLC and sets the panel length and cuts the panel automatically.

4. The main body is welded with type "H" section steel as its material, strong strength.

5. The roll forming machine is adjustable, the suitable width range is 600-1250mm

6. The roller martial is medium carbon alloy steel, with high quality.

7. The length of double belt laminating machine could be made according to customers’ needs.

Technical Parameters of Multifunctional PU sandwich panel continuous line:

ITEM | UNIT | PARAMETER |

Effective length of laminating machine | mm | 18000--36000 |

Effective width of laminating machine | mm | 1200 |

Effective height of laminating machine | mm | 20--100 |

Laminating machine temperature control range | °C | ≤80 |

Foaming casting machine flow | Kg/min | 6--25 |

Anti-pressure capability of laminating machine (25°C) | Mpa | 3 |

Anti-pressure capability of laminating machine (70°C) | Mpa | 2.8 |

Suitable production thickness | mm | 20--100 |

Capacity | m³/24h | 200 |

Dimension L*W*H | Mm | (40000--60000)*3000*4000 |

Installed power | KVA | 45 |

Total weight | Tons | 40--72 |

- Q: Characteristics of sandwich panels

- Light weight, less than 24kg per square meter weight, can fully reduce the structural cost.

- Q: How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- Outside the wire is a pipe, that is, through the pipe laying, if the pipe is galvanized steel pipe, and buried in the wall, floor, floor and so on inside can not see, it is called galvanized steel pipe concealed.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- Now the mainstream is rock wool board, but now the profit is not high, other equipment is still in the monopoly of foreign countries, I don't know what kind of you produce, but I hope you can produce new varieties.

- Q: What is the color steel sandwich board?

- The intermediate sandwich panel is two color steel with polyurethane foam with a layer of insulating material.

- Q: Can the sandwich board adhere to the plaster line?

- Carpentry board is big core board, it is solid wood to spell, gesso board is gesso to make, outside a layer of kraft paper, two material is different. Wood board is commonly used materials currently Jiezhuang, generally used as lining making furniture, door, use is very extensive. Gypsum board is generally used for ceiling, television, wall and so on, but it needs carpentry rendering.

- Q: What's the difference between sandwich board and composite board?

- Building insulation board industry, insulation composite board refers to sandwich board, composite board is popular name.

- Q: Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q: What does color steel sandwich board mean?

- The forming of the outer steel plate fully takes into account the structural and strength requirements, and takes into account both the beauty and the appearance of the inner layer to form a flat plate to meet various requirements.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Engineering sandwich plate decoration, wall structure in construction completed, outside the installation of doors and windows, clean air conditioning indoor ceiling above the air supply pipe, various pipes, cable and wiring pipe, pipe insulation after the completion of a special decoration engineering.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America Eastern Asia Africa Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 25000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Multifunctional PU Sandwich Panel Continuous Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 sets per year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords