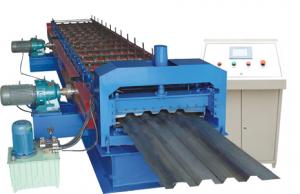

Sandwich panel Roll Forming Machinery -PRL-8-KB1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

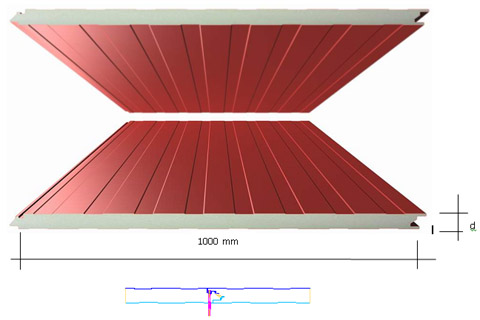

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

Sandwich panel, as a new building material,shows excellent performance on insulation.

It is taking the place of brick to be a main material for building now.

High speed slitting and cut to length can cut steel with thickness from 1mmto 16mm, if no need slitting thickness up to 30mm.

Processing flow is as following:

Carry coil→load coil→de-coiling(pressing guide +opener)→entry、rough level→cutting→transition→guide→slitting (waste winding) →looping storage→pre-separating, damping→recoiling →packing→discharging→guide→leveling→fix size (end plate feeding)→cutting→discharging

Technical Data:

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

- Q: How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- Outside the wire is a pipe, that is, through the pipe laying, if the pipe is galvanized steel pipe, and buried in the wall, floor, floor and so on inside can not see, it is called galvanized steel pipe concealed.

- Q: How to thread the EPS (color steel) sandwich panel?

- It depends on understanding! It is always more difficult than the way!

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

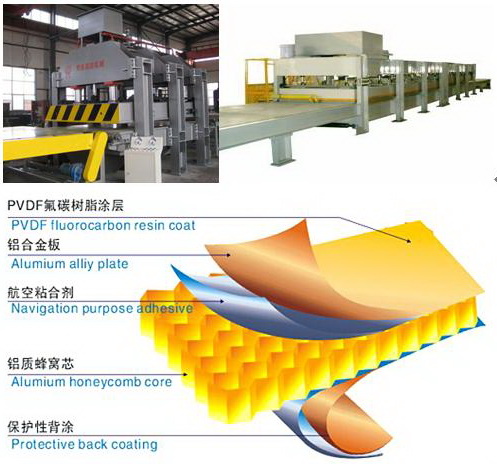

- Now there is the middle lane is a honeycomb galvanized plate board online, I know this is the direction of future development is the absolute fire, there is air, that summer is not too hot, winter is not too cold.

- Q: How is the sandwich plate synthesized?

- The forming of the outer steel plate fully takes into account the structural and strength requirements, and takes into account both the beauty and the appearance of the inner layer to form a flat plate to meet various requirements.

- Q: What is the color steel sandwich board?

- Play a role in heat insulation, there is foam, plus rock wool, in which the foam is a heat resistant material, rock wool is fire retardant material (not burning).

- Q: Can the sandwich board adhere to the plaster line?

- First brush on white latex (polyvinyl acetate emulsion), and then self tapping nails will be fixed on the wood board gypsum board, silk nail head must be slightly concave into the gypsum board, so as not to destroy the plaster board surface of the layer of paper for the most appropriate

- Q: Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- Uneven heating of sheet material leads to uneven solidification of Pu material.

- Q: What does color steel sandwich board mean?

- The finished products of the sandwich panel are easy to install, light and efficient. The filling system also uses the closed bubble molecule structure to prevent the condensation of water vapor.

Send your message to us

Sandwich panel Roll Forming Machinery -PRL-8-KB1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches