Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Description

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA8xxx Mill Finished Aluminum Coils D.C Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

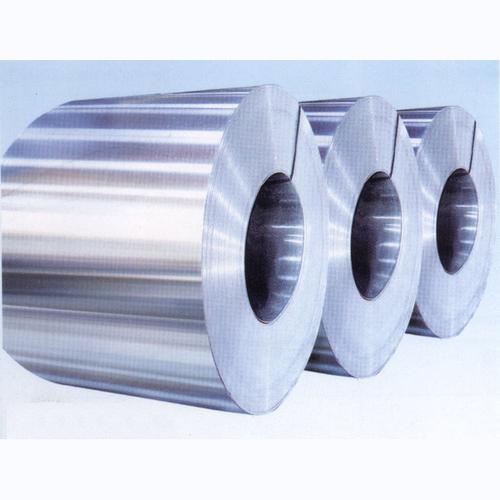

3.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Images

4.AA8xxx Mill Finished Aluminum Coils D.C Used for Construction Specification

| Alloy | AA8xxx (AA8011,AA8006 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32, O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of AA8xxx Mill Finished Aluminum Coils D.C Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- Go to an automotive paint store like Sherwin Williams Auto Paints, buy a stripper for the type of paint on the aluminum. Many are epoxy or special acrylics like acry glo or jet glo paints and home paint strippers usually won't phase those paints. A methylene chloride mixed with a soap or wax carrier will work but is a hazmat item and has to be disposed of properly but it won't be corrosive to the aluminum. Dupont, Sherwin Williams, and others make the proper strippers. You might even find some at an RV or Boat supply.

- Q: Explain how aluminum coils impact transportation, including considerations for logistics and safety.

- <p>Aluminum coils significantly affect transportation due to their weight and size. They are heavy and bulky, which requires specialized vehicles for transportation to ensure stability and prevent damage. The weight of aluminum coils can impact fuel efficiency and may require more powerful vehicles, increasing fuel consumption and emissions. Additionally, the transportation of aluminum coils must adhere to strict safety regulations to prevent accidents, especially when transported over long distances or on public roads. This can involve securing the load properly, using appropriate transport methods, and ensuring drivers are trained to handle heavy loads. The logistics of transporting aluminum coils can be complex, requiring careful planning and coordination to minimize delays and costs.</p>

- Q: This question asks about the various classifications of aluminum coil based on their properties and applications.

- <p>Aluminum coils are categorized into different grades based on their alloy composition and applications. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicone alloys). Each grade has unique properties such as formability, strength, and corrosion resistance, which make them suitable for specific applications like construction, transportation, and packaging. The selection of the grade depends on the performance requirements of the end product.</p>

- Q: Are aluminum coils suitable for electrical conductors?

- Yes, aluminum coils are suitable for electrical conductors. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity. It has around 61% conductivity of copper, which is the most commonly used metal for electrical conductors. Aluminum coils are lightweight, cost-effective, and have good thermal conductivity, making them a popular choice for various electrical applications. However, it is important to note that aluminum has a lower tensile strength compared to copper, so it may require a larger cross-sectional area to achieve the same level of current carrying capacity. Additionally, proper insulation and connectors are necessary to prevent oxidation and ensure efficient electrical conductivity in aluminum coils.

- Q: What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues that can be found in aluminum coils include: 1. Scratches: These are visible marks on the surface of the coil caused by contact with abrasive materials or improper handling during production, transportation, or storage. 2. Streaks: Streaks are long, narrow lines or bands that appear on the surface of the coil. They are often caused by irregularities in the rolling process or the presence of impurities in the aluminum material. 3. Dents: Dents are localized depressions or deformations on the surface of the coil. They can occur due to mishandling, accidental impacts, or improper storage practices. 4. Corrosion: Aluminum is generally resistant to corrosion, but certain environmental conditions or exposure to corrosive agents can lead to the formation of oxide layers or pitting on the surface of the coil. 5. Edge cracks: These are cracks or fissures that occur along the edges of the coil. They can be caused by improper cutting or shearing techniques during the manufacturing process. 6. Surface roughness: Surface roughness refers to an uneven or bumpy texture on the surface of the coil. It can be a result of inadequate smoothing or finishing during the rolling or processing stages. 7. Oil stains: Oil stains are dark or discolored areas that appear on the surface of the coil. They can occur due to improper cleaning or lubrication during the production process. 8. Coil set: Coil set refers to the tendency of the coil to retain a curvature or shape after unwinding. It can be caused by stresses induced during rolling, coiling, or cooling, leading to a non-flat and uneven surface. 9. Roll marks: Roll marks are patterns or imprints left on the surface of the coil by the rolling mill or equipment. They can be caused by uneven pressure or improper alignment of the rolling tools. 10. Discoloration: Discoloration refers to changes in the color or appearance of the aluminum surface. It can occur due to exposure to high temperatures, chemical reactions, or oxidation. These surface defects or issues can negatively impact the appearance, quality, and performance of aluminum coils. Manufacturers and users should be aware of these defects and take appropriate measures to prevent or minimize their occurrence.

- Q: Can aluminum coils be used in outdoor or exposed applications?

- Outdoor or exposed applications can utilize aluminum coils. The reason behind this lies in aluminum's remarkable resistance to corrosion, rendering it appropriate for outdoor purposes. It develops a safeguarding oxide layer on the surface, preventing further oxidation. Furthermore, aluminum is renowned for its lightweight nature, durability, and impressive strength-to-weight ratio, making it a favored option for outdoor tasks where weight and durability are crucial aspects. Aluminum coils frequently find their use in outdoor applications like HVAC systems, roofing, gutters, and siding, as they possess the ability to withstand exposure to diverse weather conditions without compromising their performance or aesthetic appeal.

- Q: Is it possible to use aluminum coil as a material for crafting jewelry?

- <p>Yes, you can use aluminum coil to make jewelry. Aluminum is lightweight, affordable, and easy to work with, making it a popular choice for crafting. It's also hypoallergenic, which is a plus for those with metal sensitivities. However, it's softer than metals like sterling silver or gold, so it may require more care to prevent denting or bending. Aluminum can be shaped, cut, and polished to create various jewelry designs, but it may not hold up as well over time or under heavy use compared to harder metals.</p>

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: what is the final temperature of 250g of water whose initial Temperature is 25 C if 80-g of aluminum initially at 70 C is dropped into the water? The specific heat of aluminum is 0.215 cal/C g how do you do it? our teacher did not show us how and it is not in the book

- Given Data :-- Mass : Aluminium m(a) = 80 g, Water m(w) = 250 g Initial Temperature : Aluminium t? = 70 C and Water t?' = 25 C Final Temperature of both ( aluminium and water ) = T C (assume) Since Aluminium is initially at a temperature higher than that of water, it (aluminium) will lose heat to water . Heat lost by Al = Q = mass of Aluminium x sp.heat capacity of Aluminium x Temp. change = Q = 80 x 0.215 x ( 70 - T ) cal Heat gained by water = Q' = mass of water x sp.heat capacity of water x Temp. change = Q' = 250 x 1 x ( T - 25 ) According to principle of calorimetery . = Heat lost by aluminium = heat gained by water. = 250 x 1 x ( T - 25 ) = 80 x 0.215 x ( 70 - T ) = T = 27.9 C .... ( Rounded to one decimal place )...... Answer Answer .

- Q: I have a 1994 Impala SS with a 5.7L lt1 engine with cast iron heads. Which is better in horsepower gain? Aluminum heads or cast iron heads? People say cast iron heads downsize the hp from 300 to 260 hp. Also which of the two heads are more durable and less restrictive?

- only difference is weight and aluminum is easier to repair

Send your message to us

Roll Aluminum Coil Michigan - AA8XXX Mill Finished Aluminum Coils D.C Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords