Revere Ware Stainless Steel Baking Sheets - Different Grade Steel Sheet Coil Plate for Choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

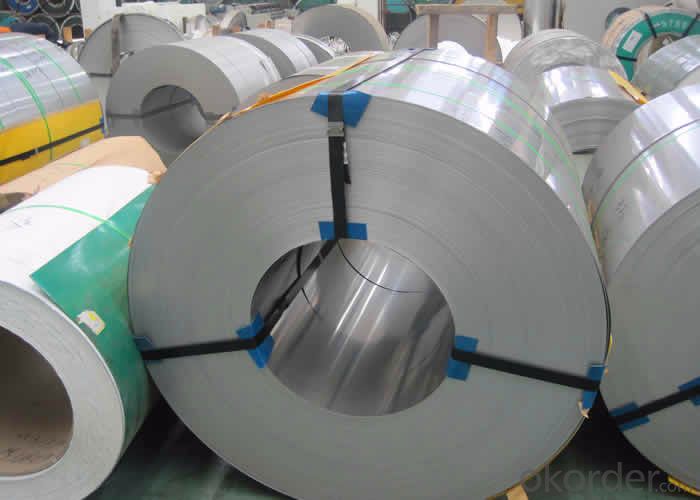

Stainless Steel Coils and Sheets

Features of Stainless Steel Coils and Sheets:

· Accurate dimension

· Suitable for heavy duty operation

· Minimum maintenance

Specifications of Stainless Steel Coils:

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.4mm-50mm

4. Width: 1000/1219/1500/1800mm

5. Length: min 1m

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Packing Information of Stainless Steel Coils and Sheets:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

Applications of Stainless Steel Coils and Sheets:

1.Automotive:Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers

4. Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q:Are stainless steel sheets good for chemical processing?

- Yes, stainless steel sheets are ideal for chemical processing due to their exceptional corrosion resistance, high strength, and durability. They can withstand exposure to various chemicals, acids, and alkalis without getting corroded or contaminated, making them an excellent choice for such applications.

- Q:Can stainless steel sheets be used for food processing equipment?

- Indeed, stainless steel sheets are capable of serving in the realm of food processing equipment. The utilization of stainless steel in the food processing industry is highly favored due to its remarkable ability to resist corrosion, its durability, and its hygienic attributes. It possesses the capacity to withstand staining, rust, and chemical harm, rendering it appropriate for both contact with food and cleaning agents. Furthermore, stainless steel sheets are simple to cleanse and uphold, thus diminishing the potential for contamination. Additionally, stainless steel remains non-reactive, signifying it does not engage with food or modify its flavor, thereby guaranteeing the safety and excellence of processed food.

- Q:Can stainless steel sheets be used for escalator steps?

- Yes, stainless steel sheets can be used for escalator steps. Stainless steel is a popular choice for escalator steps because it is durable, corrosion-resistant, and easy to clean. It also provides a sleek and modern appearance.

- Q:What are the color options for stainless steel sheets?

- Stainless steel sheets are typically available in a range of color choices, contingent upon the particular finish employed on the surface. The prevalent color selections for stainless steel sheets encompass silver, representing the inherent hue of stainless steel, in addition to black, gold, bronze, and copper. These hues are attained through techniques like powder coating, PVD coating, or chemical treatments, which establish a thin coating on the sheet's surface. The assortment of color choices grants enhanced design flexibility and the ability to select hues that harmonize with diverse aesthetics and applications.

- Q:What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q:What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q:Are stainless steel sheets suitable for chemical processing equipment?

- Yes, stainless steel sheets are highly suitable for chemical processing equipment due to their excellent corrosion resistance properties, high temperature tolerance, and resistance to chemical reactions.

- Q:How to calculate the weight of stainless steel plate?

- The formula can be calculated according to the weight of stainless steel: area m2*, thickness mm*, density = kg / sheet to calculate the weight that the stainless steel can bear.Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 argon arc welding machine! If the person who has not been married, as little as possible, that thing has radiation, long time use of physiology is influential. You know what you do.2, regardless of the front and back can be, as long as it looks beautiful and practical.3, welding technology is good, it will not be ugly after welding.4, only the use of technology to make up for the lack of machinery, and then cattle B hardware, there is no good software is not good.5, welding rod, protective mask and so on.

- Q:Are stainless steel sheets suitable for roofing applications?

- Yes, stainless steel sheets are suitable for roofing applications. Stainless steel is known for its durability, resistance to corrosion, and strength, making it an ideal material for roofs. It can withstand harsh weather conditions, including extreme temperatures, high winds, and heavy rainfall. Stainless steel sheets are also fire-resistant, which adds an extra layer of safety to the roof. Additionally, stainless steel has a long lifespan, requiring minimal maintenance and repairs. Overall, stainless steel sheets provide a reliable and long-lasting solution for roofing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Revere Ware Stainless Steel Baking Sheets - Different Grade Steel Sheet Coil Plate for Choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords