Reinforced Hollow Core Roof Panel Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforced Hollow Core Roof Panel Making Machine

1. Reinforced Hollow Core Roof Panel Making Machine:

Reinforced Hollow Core Roof Panel Making Machine works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Reinforced Hollow Core Roof Panel Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

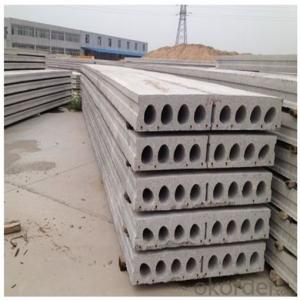

3. Reinforced Hollow Core Roof Panel Making Machine Images:

4. Reinforced Hollow Core Roof Panel Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

- Q: without and ice cream maker or blender? as dont have one. thanks

- Yes. use a spoon, whisk or spatula. SUPER EASY VANILLA ICE CREAM Time, approximately 3 hours. Yields 1 quart. 2 eggs 1/3 c. sugar 1 1/2 c. milk 1 c. heavy cream 2/3 c. light corn syrup 1 1/2 tsp. vanilla In large mixer bowl, beat eggs until light and foamy. Gradually beat in sugar, beating until sugar is dissolved. Blend in milk, cream, corn syrup and vanilla. Pour into loaf pan (9x5x3 inch). Freeze for 3 hours or until firm. Cut into cubes, place in mixer bowl and beat until smooth. Freeze until firm. EASY VANILLA ICE CREAM 2 env. unflavored gelatin 2 c. cold water 4 c. (2 pts.) light cream 2 (14 oz. each) cans sweetened condensed milk 2 tbsp. vanilla In a saucepan, mix gelatin and 1/2 cup of the water. Stir over low heat until gelatin is dissolved. Stir in remaining water. Pour mixture into a bowl and beat in remaining ingredients. Pour mixture into a 9 x 13 x 2 inch pan. Freeze until a firm mush. Cut mixture into pieces and place in a large bowl. Beat until smooth. Replace in pan, cover and freeze until hard.

- Q: If the opportunity cost of manufacturing machinery is lower in the United States than in Britain and the opportunity cost of manufacturing sweaters is higher in the United States than in Britain, then the United States will: A. export both sweaters and machinery to Britain. B. import both sweaters and machinery from Britain. C. export sweaters to Britain and import machinery from Britain. D. import sweaters from Britain and export machinery to Britain.

- D. import sweaters from Britain and export machinery to Britain.

- Q: List four fundamental differences between bacterial and eukaryotic transcription machinery.?

- Bacterial - RNAp is only of 1 type and has 5 subunits. - Sigma factor does the promoter recognition. - alphaCTD is not involved in the RNAp control, but instead binds UP elements - Poly(A) tail is not added to the RNA produced. - No introns are present, hence no splicing machinery. - GTFs are absent. - The process is relatively simple. Eucaryotes - RNAp is of more than 4 types and has about 12 subunits. - TFIIB and many other factors do the promoter recognition. - CTD of RNAp plays important role in regulation and elongation and many other processes. - Poly(A) tail is added to the RNA produced. - Splicing machinery is present due to need for intron splicing - GTFs are present. - The process is relatively very complex.

- Q: i can't find a website that gives you a list of some machines that are used in textiles in indusry. If you know anything at all, please help me, its driving me crazy.Thanks x x

- Here is the process for preparing Greige(raw) fabric for printing or dyeing. First the cloth runs through a SINGER to burn off loose material and remove seeds etc then it is bleached on bleach RANGE after that it is run down a MERCERISER to open the fibres so they will accept the dye, It is the run through a STENTER which pulls the cloth to its required width and straightens the threads or WEFT. after it is printed it may be processed on a FLASH AGER to fix the dye then its is CALENDERED to improve handle or feel.

- Q: If the pinnacle achievement of women is incubation, should we treat them as machinery?

- If the pinnacle achievement of men is insemination, should men be treated as Turkey Baster?

- Q: kinda thinking mills, maybe a conveyor belt... and i'm curious about making a steam engine (running on liquid nitrogen).thoughts? some ww2 guy wanted to build an aircraft carrier out of pykrete (ice 14% sawdust)

- try a hotel ;-). If you live in or are going to a cold climate, an ice house could be useful. You could give it power with the steam engine, and use the electricity to run a small heater, xbox, and other necessities. (i don't think a fridge would be necessary) I heard some dude actually made a working ice house like that, but it ran on solar power.

- Q: Grandfather Rights' -acceptable in a workplace for unlicensed people to train someone to operate machinery?

- You need to add additional information to your question. What machinery ? what kind of workplace? Ive never heard of anyone having to be licensed to operate machinery in a work place before.

- Q: How can I work my biceps without machinery or equipment?

- Simple. Clasp your palms together and begin with your arms straight. Then slowly curl one arm, flexing at the elbow while resisting with the other arm. You'll be doing concentric (positive) training the biceps of one while doing eccentric (negative) training of the triceps of the other arm. Do that until the muscle burns and you cannot flex any more. Good luck and good health!! ?

- Q: Plz post the cost of plastic recycling machinery in india.

- Most companies sell these machines in orders (5-10 machine shipping). One single machine costs Rs. 185,000. By the way you have to buy the washing machine separately.

- Q: Non road mobile sources include construction machinery, agricultural machinery, small general-purpose machinery, diesel generator sets, ships, railways, diesel locomotives, aircraft, etc.

- Agricultural machinery: in the production of crops, occupations and livestock production process, as well as agricultural and livestock products in the initial processing and processing of the various machinery used, the main fuel for diesel. Including tractors, agricultural transport vehicles (agricultural machinery license), combine harvesters, irrigation and drainage machinery, and other machinery, etc..

Send your message to us

Reinforced Hollow Core Roof Panel Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords