Stressing Concrete Hollow Core Panels Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stressing Concrete Hollow Core Panels Machine

1. Structure of Stressing Concrete Hollow Core Panels Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Stressing Concrete Hollow Core Panels Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

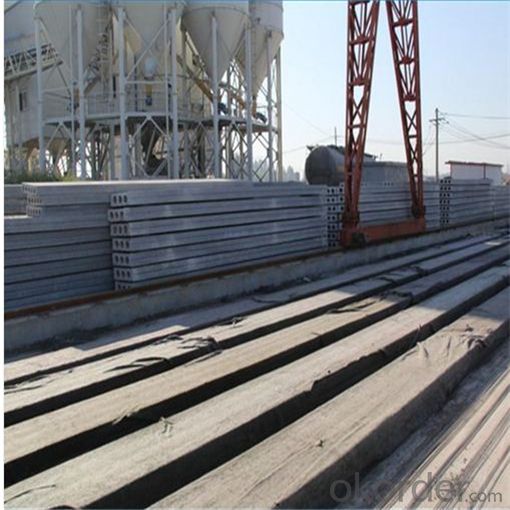

3. Stressing Concrete Hollow Core Panels Machine Images:

4. Stressing Concrete Hollow Core Panels Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: Remember before the 1980s?When we had shop classes in our schools?When we actually made products in America?When we supplied the world with steel, machine tools, and automobiles?Remember when we had a working middle class?

- Yes . A farm tractor at the age of 8 . Had to run it standing up because if you sat down you couldn't reach the pedals .

- Q: Please send me information about some company manufacturing this machinery. I have heard that some overseas companies are there.

- See: okorder

- Q: Any web site could get free machinery manual?

- actually, okorder /... Cheers nb: please visit my web site

- Q: i am looking to go to school for machinery operating like cranes, hyax bull dozers that kind of stuffand i cant find anything in troy new york. I dont know hat i am doing wrong i just recently moved up her. Can anyone help me please? thank you

- Here okorder /

- Q: when is world machinery day celebrated?

- what is world machinery day?

- Q: what are working men and women who oporate machinery called?

- lol...factory workers?

- Q: green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q: plz help! its my homework :P ugh. thanks guys xD

- The Oxford American Writer's Thesaurus does not mention any antonyms. The opposite of a machine might be human labor. Did you mean synonym? (meaning similar) ... If so, apparatus ,hardware, gear, mechanism, gadgetry, tool, engine

- Q: He plans to invest $20 000 every six months in an investment account with a view to replacing machinery. What interest rate will he need to meet his goal?(either use present formula A= P *(1-(1+i)^(-n))/ i or future formulaS = P *( (1+i)^(n) - 1)/ i, im not sure wich formula to use)PLEASE SHOW ALL WORKING OUTplease help me ITS URGENT

- 250000=20000 *( (1+i)^(n) - 1)/ i i=4.88%

- Q: I need to consult prices of aluminum rim machinery. I mean to manufacture aluminum rim and also aluminum disc to manufacture casses

- Sorry, no idea.

Send your message to us

Stressing Concrete Hollow Core Panels Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords