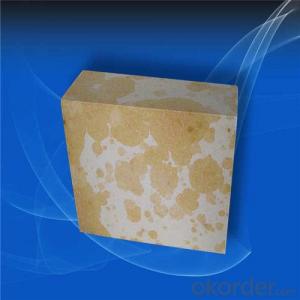

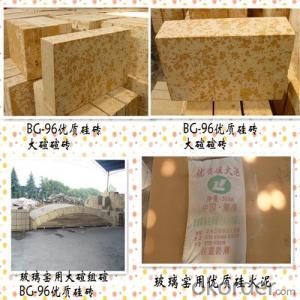

Silica Insulation Brick - Heavy Density Refractory Silica Bricks SiO2 95%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our Heavy Desity Refractory Silica Bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

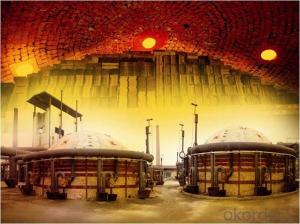

Application

Our Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

YL Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Technical Data

| Item | arch top and wall brick | lattice brick | ||

| SiO2 ≥ | 95 | 96 | 95 | 96 |

| Fe2O3≤ | 1.0 | |||

| refractoriness≥ º C | 1710 | |||

| True Density g/cm3 ≤ | 2.35 | |||

| Refractoriness under load 0.2MPa, º C≥ | 1650 | 1660 | 1650 | 1660 |

| Apparent porosity(%)AP≤ | 22 | 22 | 23 | 23 |

| Creep(0.2MPa*1550º C*50h) % ≤ | 0.8 | |||

| Thermal Expasion(1000º C) % ≤ | 1.2 | |||

| Cold crushing strength(Mpa) CCS≥ | 35 | 40 | 30 | 35 |

Photos for Applications

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: The difference between clay refractory bricks and refractory brick in the application.

- The ability of alkali resistance is poor, the thermal shock stability is the worst, and it is scrapped at one time. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Insulation Brick - Heavy Density Refractory Silica Bricks SiO2 95%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords