Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Grains

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 85% Grains

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

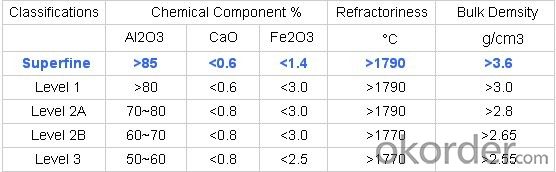

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

Pictures:

- Q: What is the best refractory company?

- Chinese brick trading network, is the most authoritative third party service platform, brought together more than 3000 refractory enterprises, working day experts online to answer, to analyze and evaluate the refractory industry, at the same time, cooperation with some refractories Association, I hope to help you!

- Q: How long is the fire-fighting time of A class fire resisting window?

- Duration of fire resistance of fire resisting window: A class window is not less than 1.2 hours; B class window is not less than 0.9 hours and C class window is not less than 0.6 hours. Technical Requirements: 1materials and accessories (1) window frame structure adopts stell framework and wooden framework that have a certain strength to ensure integrity and stability. (2) steel framework and batten can choose galvanized steel plate or stainless steel The selection criteria meet requirements of GB12955 steel fire door general technical conditions in the provisions of article 5.1. The selection criteria of wooden framework and batten meet requirements of GB14101 wooden fire door general technical conditions in the provisions of article 5.1.1. Filling material of steel and wooden framework shouldn't adopt non-combustibility material. (5) fire-fighting glass can adopt testing-qualified product that don't influence fire resistance performance of fire resisting window. Light transmittance of glass is not less than 75% of the same layer common plate glass. (6) Sealing material between framework and fire-fighting glass should adopt Flame retardant material which can serve as fire-fighting and smoke-resistant when encounter fire disaster. (7) hardware fitting should accessories product that is tested to be qualified. 二. installation requirement: 1. When Party A takes over goods, he should check numbers, specification, grades and whether Accessories are Conformed and complete according to contract.

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- You can add some animal hair, like bristles. After all, we don’t have so much hair. Remember not to use cement, because it will crack. Instead, make use of animal hair, lime, yellow mud and sand, after mixing up, and they would be firmer while in calcination.

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- Fireproof doors can be divided into three levels, namely level A,B,C. Fireproof doors of level A can endure fire for 1.50~2.00h while level B for 0.50~1.50h. However, according to national condition, the lowest fire doors fire resistance limit has been specified, namely, level A,1.50h;level B,1.00h; level C, 0.50h.

- Q: What kind of refractory materials are used in the intermediate frequency furnace?The domestic boric acid can be used as a lining?, how much is the rate?

- Acid, neutral, basic and composite materials are used in intermediate frequency furnace. Domestic boric acid is practicable. The ratio is to determined combined with material, steel (iron) species, smelting temperature, current and other factors

- Q: Can you tell me the classification of fireproof sealing material.

- Organic fireproof sealing material include: fire-proof sealing plate, foam sealing materials, flame retardant module, flexible organic plugging material, inorganic fire sealant, plugging and fire package, etc. Organic plugging material take organic materials as the adhesive with certain flexibility or plasticity when used. The product is thick liquid or cement. Inorganic plugging material take powder of solid inorganic material as the main ingredients, and admixture mixed use, with proper workability. Fireproof bag apply bag shaped object made up by fire-proof materia to large hole fire plug or cable tray fire compartmentation (fire package also called as refractory package or fire protection package). Fire modules is made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. fireproof sealing material is the plank made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. Foam block after injection holes can lathery foam and seal hole. Sealing strip is made of fire prevention materials with certain geometry shape or flexible coil geometry.

- Q: Does anyone knows which company produces the better refractory materials?

- A:Building Materials Company of Guangzhou: Near the Baiyun District, Baiyun District, Guangzhou Road, North Road. B:Guangzhou Research & Development Co., ltd.: Liwan District Fengyuan road No.90 in Guangzhou City C: Huitailong decoration materials Co., Ltd.:the 30th floor of No. 111 Pacific Center, Taikang Road, Yuexiu District Guangzhou City D:Guangdong metal materials company: Near Qishan Road, Tianhe District , Guangzhou city.

- Q: What's the A grade fireproofing material?

- A grade fireproofing material: 1. fire-proof plate; 2. fireproof wooden door; 3. fireproof wooden window frame; 4. fire resisting shutter; 5. fireproof and mothproof wood; 6. fireproof glove compartment; 8. fire?retardant?coating; 9. fire-proof?sealing?material.

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Grains

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords