Raw Materials for Refractory:Refractory Grade Calcined Bauxite 80 Pct Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 80 PCT Sands

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

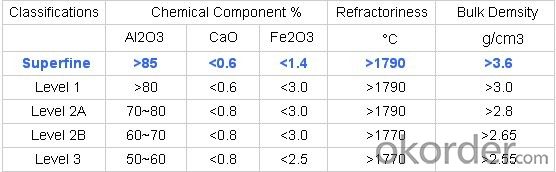

Calcined Bauxite Specifications

Size:

Sized Sand: 0~1mm

1~3mm

3~5 mm

5~8mm

8~12mm

Fine Powder:

100mesh

180mesh

240mesh

320mesh

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Pictures:

- Q: What do RH and DH stand for in refractories?

- DH :An agreement that allows strangers to build shared keys, originally invented by Diffie and Hellman.

- Q: What are the materials of insulation firebricks?

- The raw materials of firebricks, firebricks have various raw materials, and the composition of which can be divided into six categories: soil, stone, sand, mineral, powder and others. One of the raw materials, soil: bauxite, kaoline, clay, diatomite Another raw material, stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, and silica Another raw material, sand: clay sand, zircon sand, quartz sand, and magnesite Another raw materials, mineral: chromium mineral Another raw material, powder: aluminum powder, micro-silica powder, and silicon powder Another raw materials, others: asphalt, graphite, phenolic resin, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica sol, boron carbide, calcium aluminate cement, nitride material, haydite, aluminum oxide, alumina sol and zirconia, etc.

- Q: What is streaming fireproof material?

- Streaming fireproof material is castable refractory that can flow and degas without virbration, which is suitable for thin-wall or places that cannot be molded by vibration because of complex shapes. Well, appropriate amount of water is necessary for it. Its characteristic goes that it can be cast into various shapes of construction body without virbration and it will not reduce or not significantly reduce the performance of castable at the same time.

- Q: Are the specification of fireclay bricks and ordinary clay brick the same?

- Do you want to know whether the specifications of fireclay bricks and ordinary clay brick are the same?

- Q: What are the fire resistance ratings of the glass partition?

- Hello, friend. The glass partition system is composed entirely of metal structures, glass, color plate and other materials which also has fire resistance capacity. When the inner structure of the system is steel structure, the fire resistance of which is 30 mins, 60mins or even longer.

- Q: What is the appropiate thickness if fire resistant time for ultra thin steel structure coating is 2.5 hours?

- Hello steel structure can adopt surrounding concrete or brick, fireproof coating, fireproof board coating and composite structure for its fire resisitance. Fire resisitance board can be divided into thick fire protection plate and thin plate, the thickness of the plate thickness of the fire is between 20 ~ 50mm, mainly includes calcium silicate fireproof board and expansion boring stone fire board, the main varieties are KB board, CF; thin fireproof plate is between 6 ~ 15mm thick, the main varieties include enforced short fiber cement plate, ordinary enforced fiber silicate calcium board and glass cloth reinforced inorganic board.

- Q: How is refractory material made?

- It is made from yellow mud and water.

- Q: Which kind of external wall fire barrier zone material is better?

- I recommended foam cement and particulate thermal insulation composite waterproof material, which is fire isolation area product, which uses surface of vertical?plate arranged fiber technology to make the compressive?strength in the vertical direction up to above 80KPa. At the same time, under the conditions of both exterior heat insulation and effects of humiture in the long-term, it can still maintain the non-aging performance of various aspects, and safety (reliability), fire resistance and excellent durability.

- Q: What thickness is needed of the ultra-thin fireproof paint with a fireproof time of 2.5 hours?

- The thickness of steel structure fire retardant coating hasn't been regulated in the steel structure application specification (CECS24:90). The above thickness refers to a certain thickness that must (at least) achieve a certain time of the fire resistance. The thickness of fire-retardant coating in engineering is generally determined according to factory inspection report. We use thin steel structure fire retardant coating: 2.5 hours' fire resistance with the thickness of 4.9 mm; 2.0 hours' fire resistance with the thickness of 3.5 mm; 1.5 hours' fire resistance with the thickness of 1.75 mm; 1.0 hours' fire resistance with thickness of 1.17 mm. I hope I can help you.

- Q: Can polystyrene foam color steel plate be used as decorative fireproofing material ?

- Polystyrene foam plastic can not be used as fireproofing material; polystyrene foam plastic is made up of polystyrene resin as main component, foaming?agent and other additives. It is a buffer material which is most widely used[1]. It is closed hole structure, so it has low water-absorbing quality and excellent water resistance; low density, about 0.015 ~0.03; good mechanical strength, excellent buffer?performance; good machinability, easy to be moulded; good dyeing property, thermal adaptability and anti-radiation; high dimensional accuracy, uniform structure. Therefore, it has a large share in external wall thermal insulation. But it will emit polluted styrene gas when burning. It is a kind of class B material in construction.

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 80 Pct Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords