Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 85% Sands

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

Calcined Bauxite Specifications

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 |

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

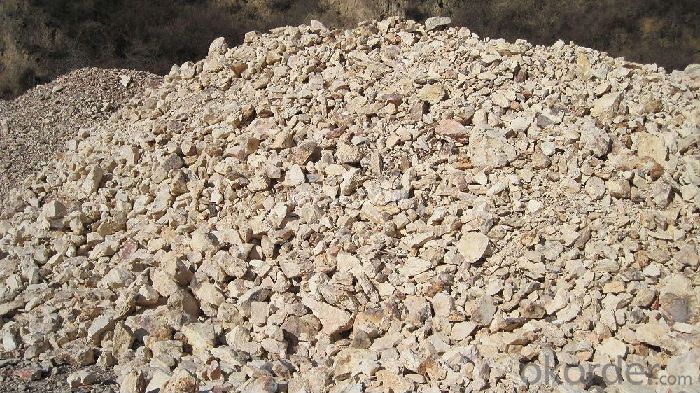

Pictures:

- Q: Who know what kind of fire shutter fire rating are there?

- There is no national standard for fire protection performance of fire roller shutter in China, and now the executive standard of GB14102-2005 "fire shutter": F1, fire-resistant time 1.50h; F2, fire-resistant time 2.00h; F3, fire-resistant time 3.00h; F4, fire-resistant time was 4.00h before the national standards of fire shutter grading is introduced, expert advice that fire resistance test be made according to national standard, to reach back fire surface temperature rise requirements, if the refractory limit is greater than or equal to 3.0h, it is said to be super fire shutter, if test not inspect unexposed surface temperature rise as a judgement of the conditions, the door is referred to as ordinary fire shutter doors. I hope my answer can help you

- Q: what kind of refractories is used to make the industrial silicon furnace mouth long life?

- Fused zirconia corundum brick, the smelter of the glassworks is used this kind of lining, and you can contact by private letter.

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of A grade fireproofing glass doors should be no less than 3 hours. A grade fireproofing glass doors use common glass of 6 mm. The shock resistance of float glass is about less than 5 min, and that of toughened glass is about 15 to 30 min. Fireproofing glass is classified in accordance with fire rating, the fire endurance of which is usually from 30 to120min, and that of the most common fireproofing glass is 60 to 90min, but now the market is a mixed bag, the so-called fireproofing glass is generally fake ultra-strong tempered glass. Therefore, you should buy the genuine glass with formal certificates, or you will bring yourself great inconvenience, and even more serious consequences.

- Q: The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q: Who knows how many fire heat preservation material are there?

- Fire proof board is a fire refractory building material for surface decoration, widely used in interior decoration, furniture, kitchen cabinets, laboratories mesa, walls and other fields. Fire board is base paper (titanium powder paper, kraft paper) processed by melamine and phenolic resin, high temperature and high pressure. 1 mineral wool board, glass wool board: mineral wool, glass wool insulation. It does not burn itself, have good performance such as high temperature resistance, light quality. Such plate have evolved into plate with inorganic adhesive material as base material, mineral wool, glass wool as reinforcing material plate. 2 cement board: High strength, wide source. In the past, it is used to make fire prevention ceiling and partition wall, but its fire resistance is poor. Cement concrete component has good heat insulation and sound insulation performance. It can be used as the partition wall and the roof panel.

- Q: How is the grading of the level A new material fire insulation material?

- The standard to distinguish level A and level B is the different fireproofing coefficient. The level A is non-combustible. The level B is divided into B1, B2 and B3. B1 is flame retardant, B2 combustible and B3 flammable. The level A is commonly phenolic aldehyde, rock wool, thermal?mortar, foam ceramics, foam glass and foam concrete on the current market. Among the advantages of level A materials, the biggest one is foam concrete currently, also known as foam cement.

- Q: Urgently!! Refractory problems, online, etc.

- The service life of most refractory materials is a pair of contradictory effects. As a result, one aspect of the contradiction is porosity, and the other is volume density. The larger the volume density is, the smaller the porosity is and the more erosion resistant, but the thermal shock effect is very poor. The bigger the porosity is, the smaller the volume density is, the better the thermal shock effect is, but it is not resistant to erosion. More professionally, two curves should be made to find the intersection of the curves to adjust the recipe and production process

- Q: Are refractory materials and fireproofing materials the same?

- Refractory materials is flammable when it is reached certain temperature for a certain time, but it will not support burning when there is no open fire (such as: gypsum board). Fireproofing material reaches A grade and it is non-combustible itself.

- Q: Who knows about the B-level fireproof insulation materials?

- Commonly used B-level materials: Molding polystyrene foam, extruded polystyrene board, gelatine powder polyphenyl granule heat insulating slurry. Although the polyurethane is not the commonly used material, but the 9mm composite of monolayer gypsum board and PU insulating material can reach B-level.

- Q: How to distinguish the fire resistant level of construction materials?

- Building materials fire resistant level is divided into four levels, among which the first level is the highest, with strongest fire resistance; fourth level is the lowest with weakest fire resistance. Fire resistance level of buildings depends on combustion performance and fire endurance of the building components. The building components refer to a series of basic components such as the building walls, foundations, beams, columns, floors, stairs, ceiling, etc.

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords