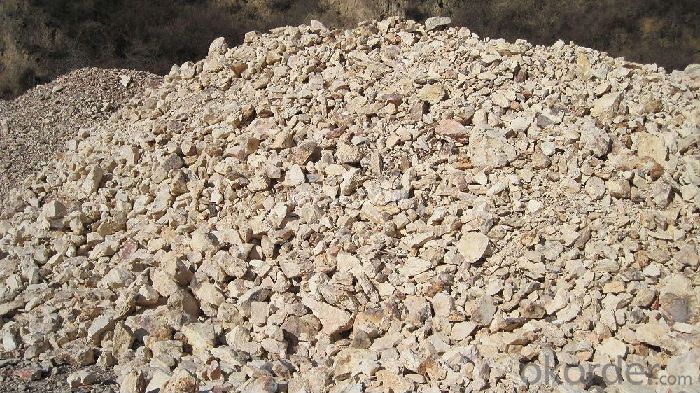

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% 0-5mm Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 85% 0-5mm Sands

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

Calcined Bauxite Specifications

| Al2O3% | CaO % | Fe2O3% | refractoriness | bulk density |

| >88 | <0.4 | <1.5 | >1790 | >3.15 |

| >85 | <0.6 | <1.8 | >1790 | >3.10 |

| >80 | <0.8 | <2.0 | >1790 | >3.0 |

| 70-80 | <0.8 | <3.0 | >1790 | >2.8 |

| 60-70 | <0.8 | <3.0 | >1790 | >2.65 |

| 50-60 | <0.8 | <3.0 | >1770 | >2.45 |

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Pictures:

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- Each country has its own fire safety standards, I do not know which country's standard do you want to know, and each country of fireproof material to the division level is not the same. GB GB 8624, the German standard DIN 4102-1, the British standard BS 476, French standard NF P92 -501 and so on. GB 8624 is Chinese building materials and grade of combustion performance. The information coming form fire resources network (FireTC.

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is used to thermal insulation and the transfer of heat insulation. refractory material is defined as greater than 1580 ° non-metallic materials, such as calcium silicate board. its using temperature can reach to 1100 degrees, and some can also be used at high temperatures, and all high-temperature industrial can't be oprated without it, and the using temperature of polycrystalline alumina fibers can reach to 1800 degrees

- Q: What are the differences and connections between softening temperature of the refractory under a fixed load and thermal resistant creep property of the refractory?

- The result of refractoriness under load is temperature while the result of creep is percentage of deformation. Refractoriness under load and creep can be tested by an instrument. Refractoriness under load reflects the temperature in which the deformation reaches a certain degree under the condition of load. Creep reflects the deformation refractory has under the condition of constant temperature and load. Both refractoriness under load and creep are important criterion for the operating temperature of refractory.

- Q: Does refractory belong to stone, building materials or other?

- It belongs to building materials.

- Q: What's the material of electrical fire prevention board?

- Industrial electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface! ! ! !

- Q: Who knows how many kinds of fireproof insulation materials are there in the market?

- The so-called A-level materials in fire insulation materials, namely, the WW non-combustible insulation materials, and the WW material s are A-level. Inorganic fireproof and thermal insulation materials can be used as wall insulation materials to replace red bricks, therefore, they, as thermal and cold insulation materials, can reduce the thickness of walls, and save energy, as well as expand applicable areas indirectly, decreased structure weight. They are very good.

- Q: Can you tell me the classification of fireproof sealing material.

- Organic fireproof sealing material include: fire-proof sealing plate, foam sealing materials, flame retardant module, flexible organic plugging material, inorganic fire sealant, plugging and fire package, etc. Organic plugging material take organic materials as the adhesive with certain flexibility or plasticity when used. The product is thick liquid or cement. Inorganic plugging material take powder of solid inorganic material as the main ingredients, and admixture mixed use, with proper workability. Fireproof bag apply bag shaped object made up by fire-proof materia to large hole fire plug or cable tray fire compartmentation (fire package also called as refractory package or fire protection package). Fire modules is made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. fireproof sealing material is the plank made up of fireproof material, which is a solid with a certain shape and size and can be easily cut and drilled, suitable for holes or fire-proof sealing of cable tray. Foam block after injection holes can lathery foam and seal hole. Sealing strip is made of fire prevention materials with certain geometry shape or flexible coil geometry.

- Q: Who knows the roofing fireproofing and waterproof material?

- Many waterproof materials are suitable for civil engineering, and almost used in the roof waterproof layer, such as: Paint categories: 911 two-component polyurethane waterproof coating single component polyurethane waterproof coating polymer cement-based waterproof coating JS composite waterproof coating and so on. . Coil categories: single-sided waterproof roll double-sided self-adhesive waterproof roll modified asphalt waterproof roll (SBS, APP) polypropylene, polyester, polymer waterproof roll, PVC waterproof roll, EPDM waterproof roll

- Q: What's the fire resistance rating of the exterior fire?retardant?coating?

- First of all, fire retardant coating has no class distinctions. Buildings fire resistance rating is generally classified as follows: I grade fire resistance, II grade fire resistance, III grade fire resistance, IIII grade fire resistance. Buildings with I grade and II grade fire resistance are much common. According to the coating thickness, exterior fire-resistant coating for steel structure can be classified as follows: 1. Exterior thin fire-resistant coating for steel structure, 2. Exterior ultra-thin fire-resistant coating for steel structure, 3. Exterior thick fire-resistant coating for steel structure.

- Q: What kinds of refractory materials that uses a-Al2o3 powder? What are the purpose of it?

- 04La-Al2O3 powder is a alumina powder whose raw material is industrial aluminum oxide which has been calcined at high temperature. It is a good polishes for ceramics and jade, meanwhile, it is also an important raw material for high-end refractory materials. The technical indicators parameters A1023 mark A1535 chemical composition AL2O3≥ 99.92 3%, ≥ 3.10FE203≤ 0.799 Refractory calcined alumina powder (a-Al2O3) 1.2 true density (g & # 47, by fully ground powder made of different fineness .O.10 0.07 0.04NA2O≤ 0.93a-Al2O3 (%) ≥ 95 95 primary crystallization average grain (um) 2 ~ 3 3 ~ 5 average particle size (um) 40 ~ 602.6SIO2≤ 0.1 0.15B2O3≤ - 0, glass, engineering ceramics typical use electronic ceramic insulating ceramic refractory ceramic wear 3

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite 85% 0-5mm Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords