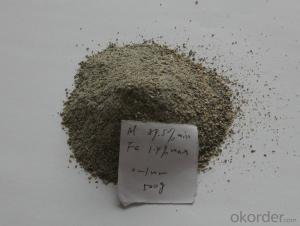

85% Min China Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

AL2O3 85%min China Calcined Bauxite Manufacture

1. Calcined bauxite

AL2O3:70% min.

FE2O3:2% max.

SIZE: 1-5MM 90% min.

china calcined bauxite manufacturer since 1999

purity of al2o3 75%-90%

rotary kiln calcined bauxite

self-owned bauxite mines

Specifications of Calcined bauxite

Grade | AL2O3 | SIO2 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

HX75 | 75min | ≤17 | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

HX80 | 80min | ≤12 | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

HX85 | 85min | ≤8 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

HX86 | 86min | ≤7 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

HX87 | 87min | ≤6 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

HX88 | 88min | ≤5 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

HX90 | 90min | ≤3 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.3 |

Moisture(max) | 0.50% | ||||||

Size of Calcined bauxite

Section sand:0-0.3mm,0-0.5mm,0-1mm,1-3mm,3-5mm,5-8mm.

Fine powder:100#-0,200#-0,325#-0

Moh’s hardness: 7-8

Melting point:1770-2000 C

Usage of Calcined bauxite

1.Aluminium industry.

2.Precision casting.

3.Refractory industry.

4.Silicic acid aluminium firefibre

5.Mixed with magnesium oxide,it can be an nice bonding agent,especially for pouring entire steel teeming ladle lining

6.Manufacture bauxite cement,grinding abrasives.ceracmic industry,and chemical industry for making aluminium compounds

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- 2,generally, the external wall thermal insulation materials is divided in accordance with fire rating: 1, the class A combustion performance of insulation materials : inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement, hole-closed perlite ect.. 2) class B1 combustion performance of thermal insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) combustion performance of class B2 insulation material: molding polystyrene board(EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope it will be helpful for you

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- It depends on the composition of the ceramic material. If its composition is alumina and it is used by civilians, its normal use temperature is 1200℃; if its composition is alumina but it is for millitary use, it can endure the highest temperature of 2200℃.

- Q: What a blast furnace refractories generally?

- Usually metal anchorage plus wear-resistant refractory spray paint. at the middle part we use high alumina bricks, corundum bricks. high duty refractory is important in improving bosh furnace lining.

- Q: How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: What things and cement mixed can act as refractory?

- This has a lot. I suggest you can check monolithic refractories.

- Q: How is the fire endurance of the fireproof paint?

- This is not specified. It depends on design requirements.The products we made have fireproof endurance ranging from 1 to 4 hours. we have not done any higher.

- Q: How should fireproof building materials be ranked?

- According to our national standard GB8624-97, the combustion performance of building materials are divided into the following levels: A class: Incombustible building materials: the material is almost incombustible. B1 class: Flame-retardant building materials: they are better in fire retardation. It is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material: It has no fire retardant effect at all, but is highly flammable with high fire risk. Hope my answer can be accepted.

- Q: What is the type of heat resistance property of high temperature electric furnace ?

- According to the levels of refractoriness : Common refractories: & Gt: 1580 ℃ ~ 1770 ℃ advanced refractories: 1770 ℃ ~ 2000 ℃ AAA refractories; 2000 ℃

- Q: What is the quote of fireproof and soundproof materials used in KTV?

- acoustic material, aluminum foil glass wool, sound-deadening material, glass wool, cinema / KTV dedicated glass wool: The classification of glass fiber products: The category of glass wool felts: The level of insulation cotton: A-level brands: New applications: The origin of GB/T13350-2008: The coefficient of thermal conductivity(room temperature): 0.035 bending at low temperature≤: 0.02 elongation at break: ≤80kPa flexure strength: ≤120kpa Compressive strength: ≤150kpa application temperature: 700 Core material: The shape of glass wool: Fibrous shape: Coil Specifications: Complete quote is 23 Yuan per cubic meter. glass wool board, KTV sound insulation core material: The shape of glass wool: The level of rectangular glass wool: A-level non-combustible brands: Kunnai material: The origin of glass fiber: Guangzhou, Shijiazhuang, Wuhan, the quote there is 8.8 Yuan per cubic meter.

- Q: What is the limit of fireproof rolling shutter?

- Fireproof rolling shutter door is a kind of fire protection and heat insulation facility which is suitable for the large openings of buildings, having a certain effect on the design and installation. Fire shutter doors are widely used in fire partition of industrial and civil building. It can effectively prevent the spread of fire, to protect the safety of life and property. It is an indispensable modern building fire facilities. According to the national standard 14102-2005 GB standard, the provisions of 14102-2005 GB specify that: If fire resistance limit of fire resisting shutter is no less than 3 hours, it is AAA fireproof rolling shutter. Therefore, the fire resistance limit of AAA grade fireproof rolling shutter should be 3 hours.

Send your message to us

85% Min China Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords