Recycled Aluminum Sheets 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

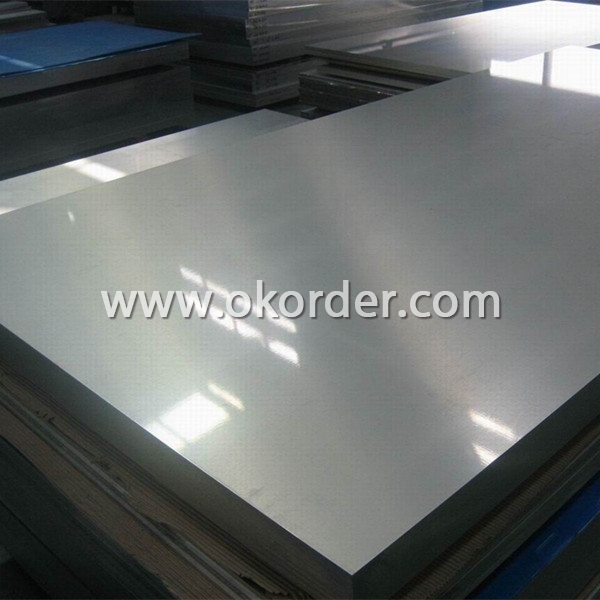

1 Specifications of Aluminium Plates 1XXX

|

Alloy Number |

AA1050 , AA1060 ,AA1070 ,AA1100 etc. |

|

Temper |

H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

|

Thickness |

0.1mm – 500mm |

|

Width |

10mm- 2200mm |

|

Standard |

GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminium Plates 1XXX

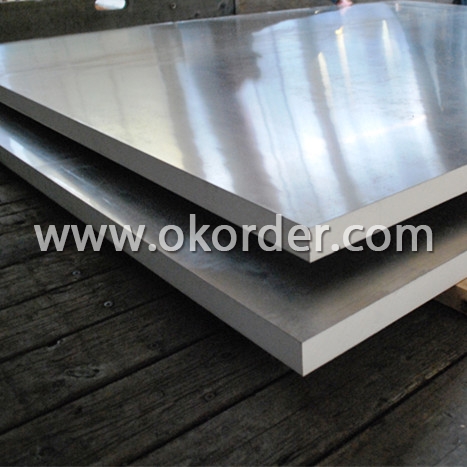

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Aluminium Plates 1XXX

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminium Plates 1XXX

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Alright - first, find the number of moles of aluminium in that sample, by dividing the mass (0.47g) by the molecular weight of aluminium (26.98). Then, having obtained the number of moles, multiply it by the avogadro's constant (6.023x1023) and you will obtain the number of atoms, and by dividing the mass by the number of atoms, you get the mass of an individual atom.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: What are the common sizes of aluminum sheet?

- Common sizes of aluminum sheets vary depending on the specific requirements and industry applications. However, some standard sizes are commonly available in the market. These sizes typically range from 0.025 inches to 0.125 inches in thickness and can come in various widths and lengths. Some common width options include 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Additionally, aluminum sheets can also be found in smaller sizes, such as 12 inches by 24 inches or 24 inches by 24 inches, which are often used for smaller projects or crafts. It is important to note that custom sizes can also be obtained through specialized aluminum sheet suppliers.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: Can aluminum sheets be used for decorative ceiling panels?

- Yes, aluminum sheets can be used for decorative ceiling panels. Aluminum is a versatile material that offers many benefits for this purpose. It is lightweight, durable, and corrosion-resistant, making it suitable for long-term use. Additionally, aluminum sheets can be easily shaped and molded into various designs, patterns, and textures to create visually appealing ceiling panels. These panels can be finished with different coatings or finishes to enhance their aesthetic appeal and match the desired decor style. Furthermore, aluminum is a sustainable and eco-friendly material as it can be recycled, making it an ideal choice for those who prioritize environmental consciousness. Overall, aluminum sheets are an excellent option for decorative ceiling panels due to their versatility, durability, and aesthetic potential.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Computer cooling aluminum plate, mainly using 6063 T5 high quality aluminum and high quality copper, they are mainly used to make aluminum extrusion fin. 6063 T5 high-quality aluminum material can reach more than 98%, and its heat conduction ability, small density, cheap price, so get the love of major manufacturers.At present, the common aluminum extrusion fins are made of copper and aluminum alloy, and each of the two has its own advantages and disadvantages.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can be used for architectural applications. Aluminum is a versatile and lightweight material that offers excellent strength, durability, and corrosion resistance. It can be easily formed, shaped, and fabricated into various architectural elements such as façades, roofs, windows, doors, and cladding. Its aesthetic appeal, along with its ability to withstand harsh weather conditions, makes it a popular choice in contemporary architectural designs.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Indeed, it is possible to paint or coat aluminum sheet after it has been fabricated. Aluminum, being a versatile material, lends itself easily to being painted or coated in order to improve its appearance or provide extra protection. The procedure involves preparing the surface through thorough cleaning and the elimination of any impurities, followed by the application of a primer to enhance adhesion. Once the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The choice of paint or coating will depend on the intended usage and the specific requirements of the application. All in all, painting or coating aluminum sheet after fabrication is a widespread practice that can significantly enhance its aesthetics and durability.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Green People's deodorant doesn't have aluminium or parabens; many people avoid these to be on the safe side. Please be aware though that 'deodorants/anti-perspirants cause breast cancer' is an urban myth. There is no evidence that this is the case and the email that did the rounds a while ago was a hoax.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Recycled Aluminum Sheets 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords