16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

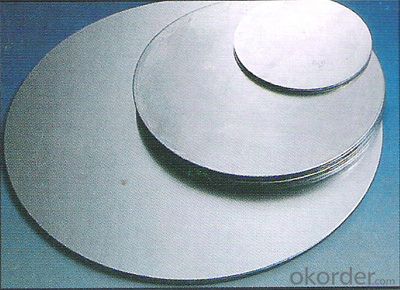

1.Structure of Re-Roling Aluminium Circle for Deep Drawing

Re-Roling Aluminium Circle for Deep Drawing is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Re-Roling Aluminium Circle for Deep Drawing

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Aluminum cans melt at about 1220 F. Lava is about 1300F to 2400F. The can would melt into the lava.

- Q: Can aluminum sheets be used for battery enclosures?

- Yes, aluminum sheets can be used for battery enclosures. Aluminum is a widely used material for battery enclosures due to its excellent properties. It is lightweight, corrosion-resistant, and has good conductivity. These characteristics make it suitable for protecting batteries and ensuring their optimal performance. Aluminum's high strength-to-weight ratio also allows for the construction of sturdy yet lightweight enclosures, making it an ideal choice for various battery applications. Additionally, aluminum is easily recyclable, making it an environmentally friendly option. Overall, aluminum sheets are a viable and commonly used material for battery enclosures.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability. Aluminum is a soft and lightweight metal that possesses excellent formability characteristics, making it highly suitable for various shaping processes. It can be easily bent, folded, or formed into different shapes using a variety of techniques such as press braking, roll forming, or stretch forming. The malleability of aluminum allows it to be easily molded into intricate shapes without cracking or breaking. Additionally, aluminum's low melting point makes it possible to heat and shape it further using processes like hot bending or thermoforming. Overall, aluminum sheets offer great flexibility and ease of shaping, making them a popular choice in industries such as automotive, aerospace, construction, and manufacturing.

- Q: Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- It costs several cents more to manufacture 10 single dose vials that do not require mercury, than one multi-dose vial that does require mercury. Your health is worth just a few cents to these people. Aluminum is used in non-live virus vaccines in order to cause inflammation in the body, which produces a stronger immune response to the vaccine.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a popular choice for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. Aluminum fins allow for efficient heat transfer between the fluid and the surrounding environment. Additionally, aluminum sheets are easily formed into various fin shapes and sizes, providing flexibility in design. Overall, aluminum sheets are a suitable and commonly used material for heat exchanger fins.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum sheets are lightweight, making them easy to transport and install. This reduces the overall weight of the furniture, making it more manageable during assembly or rearrangement. Additionally, the lightweight nature of aluminum sheets allows for more flexibility in design, enabling manufacturers to create intricate and unique furniture pieces. Secondly, aluminum sheets are highly durable and resistant to corrosion. Unlike other materials like wood or steel, aluminum does not rust or deteriorate over time, making it suitable for both indoor and outdoor furniture. This durability ensures that furniture made from aluminum sheets has a longer lifespan, reducing the need for frequent replacements. Furthermore, aluminum sheets are highly malleable, allowing for easy shaping and customization. This flexibility in design enables furniture manufacturers to create furniture with intricate patterns, curves, and contours. Aluminum sheets can be easily molded into various shapes and sizes, providing endless possibilities for creativity and innovation in furniture design. In addition, aluminum sheets are low maintenance. They are easy to clean and require minimal upkeep, saving time and effort for both manufacturers and consumers. This makes aluminum sheets an ideal choice for furniture in high-traffic areas or public spaces where regular cleaning is necessary. Moreover, aluminum sheets are environmentally friendly. Aluminum is a highly recyclable material, meaning that furniture made from aluminum sheets can be easily recycled at the end of its life cycle. This reduces the impact on the environment and promotes sustainability in the furniture industry. Lastly, aluminum sheets offer excellent thermal conductivity. This means that furniture made from aluminum sheets can absorb and dissipate heat efficiently, providing comfort to users. In applications like outdoor furniture or items exposed to sunlight, aluminum sheets can prevent overheating and maintain a comfortable temperature. Overall, the advantages of using aluminum sheets in the furniture industry include their lightweight nature, durability, malleability, low maintenance, environmental friendliness, and excellent thermal conductivity. These properties make aluminum sheets a popular choice for furniture manufacturers, allowing them to produce high-quality, innovative, and long-lasting furniture pieces.

Send your message to us

16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords