pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

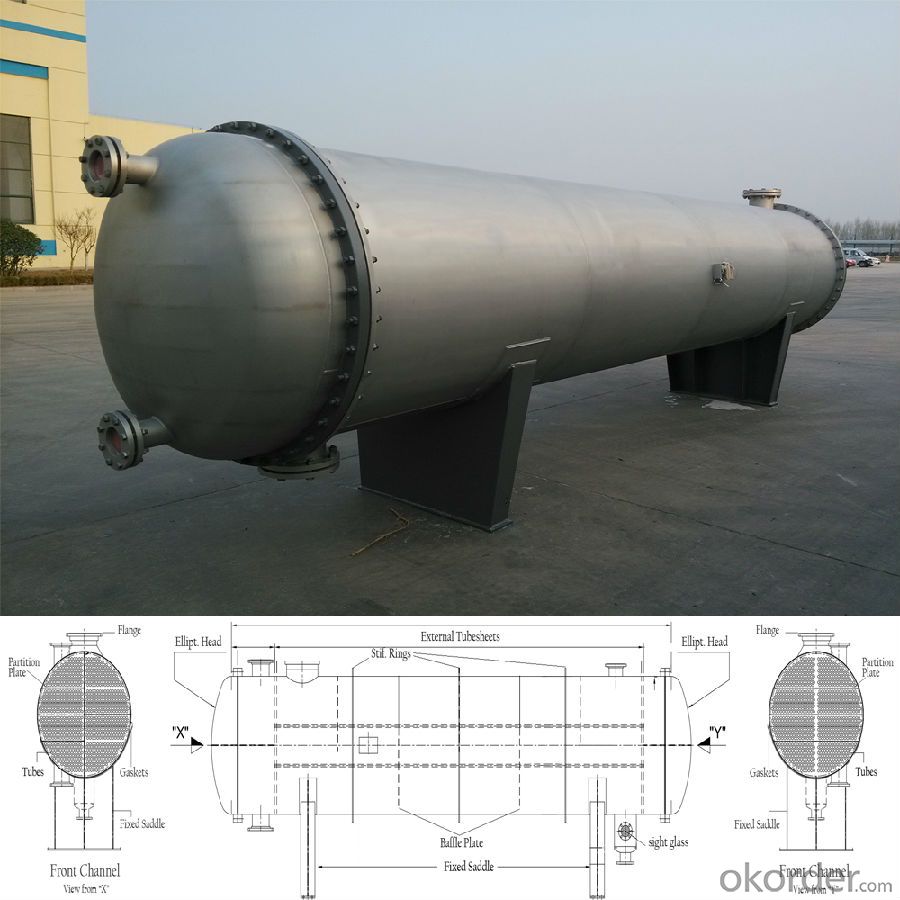

Pre-heater is a high-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid.

The heatexchangeris divided into tubular heat exchanger, spiral plate heat exchanger.And the tubular heat exchanger comprises condenser, Pre-heater, Re-boiler,Evaporator, drying machine. The spiral plate heat exchanger comprisesnon-dismountable and dismountable exchanger.

The heatexchanger is made of carbon steel and stainless steel.

2.New Technology Description:

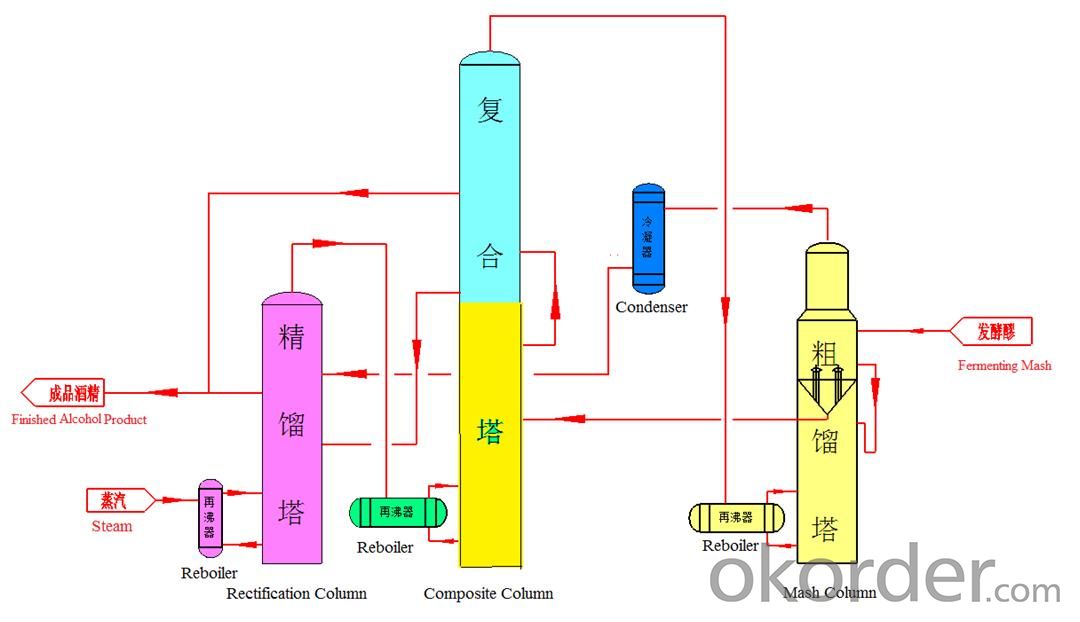

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latest Five-Column Three-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

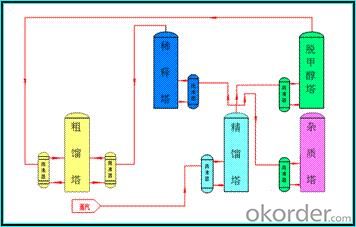

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2).We can reach the project site after receiving the user’s notification.

6.Package & Transport

- Q: I am well aware of many technologies that require heat transfer (Heat Engines, Peltiers, Thermocouples, etc.), but all of them require heat transfer.I was wondering if it were possible to extract the heat energy from a body.

- Your body makes heat so yes you can do heat transfer from the body. Look up how all heat transfer systems work and simply use the person as the source of heat.

- Q: actually i want to know how to define the power required for air cooled heat exchanger fan.thanx!

- So you want to specify the AC power needed for the fan? Decide how much air flow you need, and how big the blades are, then search for a fan on the internet that meets that spec.

- Q: How do you say "The Exchanger" in Spanish, French, and Italian?

- French = L'échangeur

- Q: expalin with functions, futures and name of the heat exhangers spares.

- A typical heat exchanger is the shell and tube heat exchanger which consists of a series of finned tubes, through which one of the fluids runs. The second fluid runs over the finned tubes to be heated or cooled. Another type of heat exchanger is the plate heat exchanger. It directs flow through baffles so that the fluids are separated by plates with very large surface area. This plate type arrangement can be more efficient than the shell and tube. Advances in gasket technology have made the plate type increasingly practical. A third type of heat exchanger is the regenerative heat exchanger. In this, the heat from a process is used to warm the fluids to be used in the process, and the same type of fluid is used either side of the heat exchanger. (These heat exchangers can be either plate and frame or shell and tube construction.) A fourth type of heat exchanger uses an intermediate fluid or solid store to hold heat, which is then moved to the other side of the heat exchanger to be released. Two examples of this are adiabatic wheels, which consist of a large wheel with fine threads rotating through the hot and cold fluids, and heat exchangers with a gas passing upwards through a shower of fluid (often water) and the water then taken elsewhere before being cooled. This is commonly used for cooling gases whilst also removing certain impurities, solving two problems at once.

- Q: A heat exchanger is used to heat cold water at 8 C entering at a rate of 1.2 kg/s by hot air at 90 C entering at rate of 2.5 kg/s. The heat exchanger is not insulated, and is loosing heat at a rate of 28 kJ/s. If the exit temperature of hot air is 20 C, the exit temperature of cold water is (use constant specific heats at room temperature)Stuck on this heat exchanger.Please show steps and how to get the answer. Possible 37.5 C

- in case you study the manufactuers instructions on installation, it really is going to allow you to recognize that Combi Boilers at the instant are not cautioned for showers.the reason being, that you're drawing off warm water, speedier than the Combi Biler can warmth the water, and so it runs chilly after a lengthy time period.The old boiler gadget change into positive for a bath, because the nice and cozy water provide got here from a large warm water copper tank the position the nice and cozy water change into saved. you need to position in an electric powered bathe once you've a Combi boiler. there is not any way of overcoming this difficulty.

- Q: We bought a pool last year and it never went past 72. The pool this year is 68 with no signs of it changing. We have tried a solar cover and filtering the water through a hose into hot coals and back which actually made it worse. Is there anything else we can do???

- This one would take some serious engineering............. Does the wood burning stove have a wet back? In other words it heats water. If that is the case you may have a chance you will need to fit a pipe from the bottom of the pool to the lower point on the water boiler part of the stove then take another pipe fix it to the highest connection point on the water boiler and connect the other end to the top of a holding tank ( Make sure the holding tank is higher than the boiler unit on the stove. Then from the from the base of the holding tank connect a pipe that will take hot water back to the pool. You will not need a pump for this if the system is well sealed. You will just have to make sure there is water and in all parts of the circuit and not air locks. When the stove heats the water the hot water will rise to the holding tank and and at the same time cold water will be drawn into the lower part of the boiler.

- Q: Just changed the impeller on my engine and the water is pumping well now. Only problem is I need to get into the saltwater/fresh system to replace the filter. The cap will not for the life of me come off!! Its the big round one on the left (not the radiator side) I have attempted to get it off much to my disappointment, it only should need half a turn then come off right? Any help would be appreciated. Its a new boat i have purchased and just doing all the things so she runs mint. Thanks

- You need to push down on the cap before you turn it. The water strainer only needs to be cleaned from time to time. It a plastic basket type filter. These are great running engines. Good luck! EDIT/ No the cap should be OK. Impellers last 2/3 years on average. The water filter strains out stuff that could plug the system. I clean mine about every 20 hours of use. It's easy once you figure out how to get the cap off. I'm glad I was of some help.

- Q: What is a hybrid heat exchanger?

- In the case where the fluids are allowed to mix with each other, mixed heat exchangers such as gas washing and cooling, cooling of circulating water, mixing heating between steam and water, condensation of steam, and the like can be used.

- Q: I'm guessing there's something I haven't checked. I've replaced the air filters and vents but everymorning I wake up when the heatings been on that night I have a sore throat and stuffed up nose. Any HVAC geniuses out there? Thanks.

- Not sure where you live but I would suspect you are in a dry climate. I have forced air heating using natural gas but I live in a climate where the humidity is quite high. I believe you are experiencing these difficulties from the drying action in your nose and throat from the hot dry air being circulated by your forced air fan. I could only suggest the use of a humidifier to help relieve this condition. If you are not in a dry type of atmosphere you've got me. Have you had you furnace checked for a leak in the heat exchanger ( usually if the furnace is over 15 to 20 years old it has this potential. A leak in the heat exchanger can cause CO (carbon monoxide) to be blown into the rooms through the heating ducts. This could cause more serious problems but if your furnace is of that vintage you should get it checked, good hunting!

- Q: From time to time my heater will suddenly start throwing out cold air the thermostat will go down 5-10 degrees lower than it's set at for several hrs. Then for no reason it will start giving out warm air again like it's supposed to. Sometimes it will even go 1-2 degrees higher than originally set before clicking off. It's done it a couple of times a month all this winter. Besides being cold I presume it's wasting energy money. This is the second year it's done it. But it doesn't do it in the summer with the cooling. I use electric for cooling gas for heating. Anyone have any ideas? My nephew has worked with heating/cooling units at work but never heard of anything like this.

- Sounds to me like a fan limit switch sticking closed. That is the component responsible for running the fan until the remaining heat is removed from the heat exchanger. (to keep it from cracking) But, it only does what the thermostat tells it do do.... The heater not initializing and then running too long is the anticipator in the thermostat not set right or not working at all. That component is responsible for turning on the heat before it cools off too much and then telling the heat to shut off before it gets too hot,.... to even out the temperature swing. Your best bet would be to try to get your hands on an old analog thermostat. That may iron out the whole problem.

Send your message to us

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords