Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Customised solutions for your kilns

2.repair service

3.furnace construction service

4.high mechanical strength

5.ISO9001

1)Refractories for insulation of furnaces and kilns

2)Refractories to meet high-temperature erosion / corrosion

3)Refractories to take high-temperature loads

4)Refractories for continuing improvement in production & performance

5)Refractories for cost-effective manufacturing solutions

Physical & Chemical Properties of Refractory LH-85B

Product Name | Specialized castable for coal burner tube | Corundum Andalusite Castable For Burner | |||

Product Code | LH-80P | LH-85P | LH-70P | ||

Density(kg/m3) | ≥2.75 | ≥2.75 | ≥2.60 | ||

Chemical Component (%) | AL2O3+SiC | ≥75 | ≥80 | ≥70 | |

Cold Crushing Strength(MPa) | 110°C*24h | ≥90 | ≥90 | ≥80 | |

1100°C*3h | ≥100 | ≥110 | ≥90 | ||

1350°C*3h | ≥100 | ≥120 | ≥85 | ||

Modulus of Rupture(MPa) | 110°C*24h | ≥9 | ≥10 | ≥7 | |

1100°C*3h | ≥11 | ≥12 | ≥7 | ||

1350°C*3h | ≥12 | ≥13 | ≥10 | ||

Linear Change Rate(%) | 1100°C*3h | ±0.3 | 0.25± | ± 0.3 | |

1350°C*3h | ± 0.4 | ±0.4 | ±0.4 | ||

Maximum Service Temperature(°C) | 1600 | 1650 | 1600 | ||

Construction Method | Pouring& Vibrating | ||||

Application Area | Coal burner tube and high-temperature parts | ||||

Construction Service & Regulations

1.Check the size, specification, layout, installation and quality of the metal anchorage and make expansion

processing of the anchors.

2.Erect the formworks (hardwood or steel) in advance.

3.Unpacking and pouring the castable

4.Mixing

5.Installation of the mixed castables & Large area constrction

6.Vibrating

7.Before the castable block get final set,it can not bear any pressure or vibration.

8.Curing & Stripping

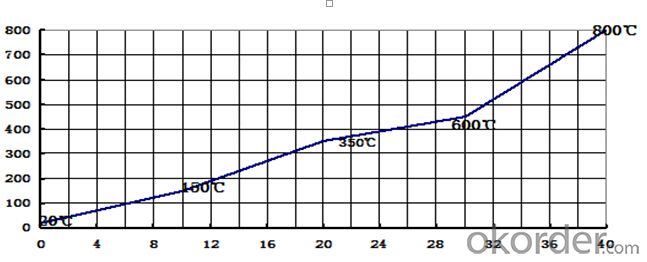

9.Baking the Furnaces (taking cement plant kiln as an example):

1). Keep the initial temperature at 20°C or so.

2). Please strictly follow the curve to conduct the baking work and increase the temperature smoothly and

evenly.

3). Lay out as many temperature measuring points as possible to monitor the temperature in the kiln, ensuring

the stable increase of the temperature.

FACTORY:

- Q: What is the importance of silicon powder in refractory processing?

- in amorphousness it is mainly the mobility

- Q: What is the main constituent of refractory brick?

- Primarily magnesium oxide and sodium silicate as binder.

- Q: Kinds of refractory mortar

- It needs no heating when hardened. There are two kinds of refractory mortar, the finished products and semi-finished products. Clinker is compounded in proportion according to the hardening temperature. (3) Chemical bonding refractory mortar is made from refractory aggregate and chemical binders (inorganic, high alumina refractory mortar). After this refractory mortar with thermal hardness is hardened, it has some contraction. Ther is a wide variety of refractories used on the constrcuction sites: // a, Advanced refractories (1770 ~ 2000 ℃) and AAA level refractories (2000 ℃ above). It can only be delivered in dry state. Air hardening refractory mortar is often compounded air hardening binders such as sodium silicate. It will harden below ceramic bonding temperature. According to different binding agents.

- Q: Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

- Q: Urgently!! Refractory problems, online, etc.

- The service life of most refractory materials is a pair of contradictory effects. As a result, one aspect of the contradiction is porosity, and the other is volume density. The larger the volume density is, the smaller the porosity is and the more erosion resistant, but the thermal shock effect is very poor. The bigger the porosity is, the smaller the volume density is, the better the thermal shock effect is, but it is not resistant to erosion. More professionally, two curves should be made to find the intersection of the curves to adjust the recipe and production process

- Q: How to hang the suspended brick in the refractory masonry?

- First you can fasten the girder and the suspended brick with screws, and then move them to the specified location by a crane. You can contact the refractory plant in Shanshan mountain, Ningxiang Countym, Hunan Province at 0731-7150098.

- Q: What are the differences of ceramics and refractories? Is the ceramics belonging to refractories?

- The ceramics and refractories are different with the porcelain ceramic with high temperature of 1300℃ as household porcelain refractory. The porcelain refractory material of 1450℃ as the same as the aluminum oxide, kaolin, refractory clay and other raw materials demand the deployment ratio of the raw material the same as the temperature.

- Q: Is it necessary for the frame of glass fireproof door to be crammed with fire-proof material?

- Close the door , and check if the gap is normal, whether the hole and the door leaf are in the same plane, and whether the door leaf has tendency to fall down. Fire resistance steel door——means that use a cold rolled steel sheet as door frame, door plank and framework, and stuff a door leaf with incombustible material.

- Q: What kind of refractory material should be used for common boiler?

- Build by using clay refractory mortar. Common clay brick is used as combustion layer. Xindeyuan Refractory Material, red?brick is used as external wall. Light clay brick is used as thermal insulation layer, thank you.

- Q: What is glass furnace used high-grade refractory materials?

- Corundum brick, such as alumina hollow ball brick. In addition, in the key parts of the glass furnace needs to use chromium zirconium corundum material. I'm salesman of zibo lei bao refractories company. The softening temperature of corundum mullite brick is 1500 degrees. So glass melting furnace needs to use refractory materials which high temperature resistance is more than 1600 degrees.

Send your message to us

Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords