High Temperature Castable Refractory Cement - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

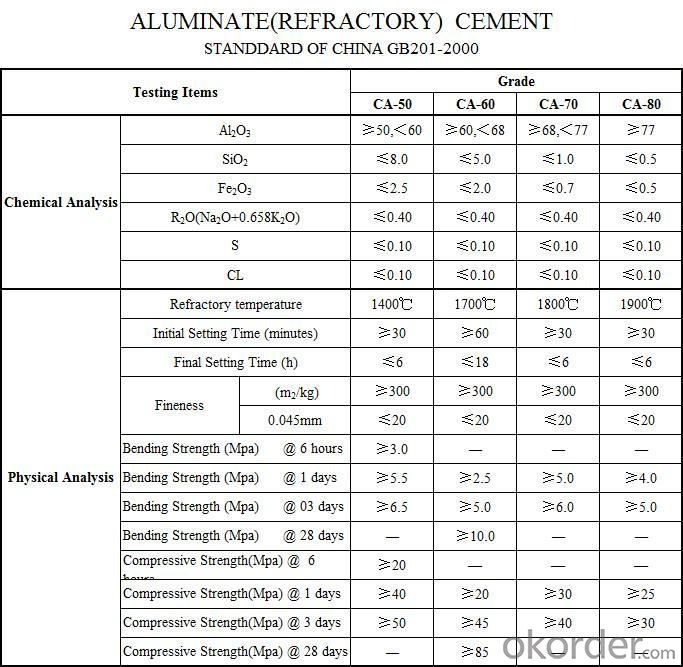

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | QIHAN | Model Number: | CA-50 |

| Color: | Brown | Feature: | Refractory | Main Raw Material: | Aluminate |

| Type: | refractory cement | Hardening Feature: | Rapid Hardening | Heat of Hydration: | Moderate Heat |

| type: | Refractory cement | Al2O3: | ≥50<60< p=""> | Refractory temperature: | 1400 ℃ |

Packaging & Delivery

| Packaging Details: | a) 50kg per bag then 40 bags into a 2mt sling bag for portland cement 42.5R b) 2mt jumbo bag of portland cement |

| Delivery Detail: | within 25 days after received payment |

Specification

Packaging & Shipping

“ Come on! you need try and trust ”

We are forwarding hand in hand together, win-win future!

We always provide the best service!

SGS inspection before shipment

- Q: What is the importance of silicon powder in refractory processing?

- it can certainly improve the fire resistance

- Q: how to use boiler fireclay

- Boiler refractory, diluted with water to touch the places where needed, can be used after high temperature baking.

- Q: What is the principal part of silicious refractory material

- Shenzhen Longgang Jiangyou Hua Boiler Accessories Co., Ltd. is specialized in refractory cement, refractory mortar, refractory clay, refractory aggregate and perlite. And other refractory | thermal insulation material, it has cooperated projects in Shenzhen, Huizhou, Dongguan, Guangzhou, Foshan, Zhuhai and other sites. For more information you can find our website on Baidu.

- Q: What refractories are resistant to fluorine gas?

- It is recommended to use fused-quartz brick, which will produce hydrofluoric acid fluorine (an acidic gas) when water vapors. It is cheap. While it is recommended to use silica?brick if it exceeds 1,200 degrees. So acidic refractory is an advisable refractory for using. It works well if the temperature is below 1200 degrees.

- Q: How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: Refractory factory grinding brick dust harmful to the body?

- The effect is very large and belongs to lung disease.

- Q: What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q: What are the types of refractory sealant?

- 1. The characters of sealant for construction According to the characters, sealant for buildings are classified into caulk, sealants and construction sealant in China; They are named in accordance with the function and different basepolymeters. In the relevant standard for products,

- Q: Which region use more refractory?

- Steel industry gathering areas use more refractories, for which you can know more details on Jinmeng website.

- Q: Can anyone tell me what is a high alumina refractory?

- High alumina refractories: High-alumina refractory products have high refractoriness, compressive strength and refractoriness under load, which are used for building the high-temperature parts of various large blast furnaces, such steelmaking furnace, airheater, electric furnace, rotary?kiln and other thermal equipment.

Send your message to us

High Temperature Castable Refractory Cement - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 40000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords