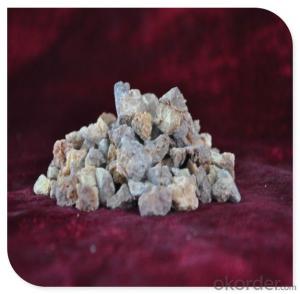

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | as per buyer choice |

| Delivery Detail: | After LC confrmation 20 days. |

Specifications

Dead Burned Magnesite

Used for refractory materials.

MGO:86-90%min and 91-95%

Size;0-5mm,0-3mm,1-5mm and+

Dead Burnt Magnesite

Used for refractory Materials,

Mgo,----------- 88-90%min, and 90-95%

Sio2,----------- 4.5%max.

Cao,------------2.5% max.

Fe203,-------- 1.5% max.

Al,---------------1.5%max.

Loi,--------- ----1%max

B.D,-------------3.15%

Size; 0-2mm, 0-5mm and others

Paking; 50 Kgs , and than into 1000 Kgs bags or, as per buyer choice.

Payment; LC at sight, with 30% advance and 70% after BL.

Note: We can also produce Fluorspar 80% and white talc of 95% whiteness.

Basic Information

| Business Type: | Manufacturer, Trading Company | |

| Main Products: | Flourspar Lumps,Talc Lumps garephite,chrome ore copper ore,manganese ore Mica,DBM | |

| Number Of Employees: | 11 - 50 People |

Trade & Market

| Main Markets: | Western Europe Eastern Asia Mid East Southeast Asia Eastern Europe North America | |

| Total Annual Sales Volume: | Below US$1 Million | |

| Export Percentage: | 81% - 90% |

Factory Information

| Factory Size (Sq.meters): | 1,000-3,000 square meters | |

| Factory Location: | peshawar, NWFP, Pakistan | |

| No. of Production Lines: | 6 | |

| Number of R&D Staff: | 5 - 10 People | |

| Number of QC Staff: | 21 - 30 People | |

| Contract Manufacturing: | CNBM |

- Q: What are the materials for refractory materials? What are their names?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: What is the requirement of refractory concrete for raw materials? What is the main principle of commercial mixing station?

- Commodity concrete stations can not be produced in general, and are made by professional fire resistant concrete manufacturers.

- Q: What's the requirements of fire-fighting criteria of heat insulating material?

- Specific provisions go as the following article 8: roof grassroots adopted duration of fire resistance is the non-combustible component that shouldn't less than 1.00 h's. Its roof insulation materials should not be below B2; Otherwise, the combustion performance of insulating material should not be below the B1 level. Article 9: The junction of the roof and wall, the insulation layer around the opening part of roof should use the grade A thermal insulation material to set level fire-fighting belt that width is not less than 500 mm. Article 10: the roof waterproof membrane or flammable insulation layer should adopt incombustible material to cover.

- Q: what's the fireproof levels of fireproof and thermal inuslation matertial?

- 1, organic materials: B level material is flammable, B1 level material is flame retardant. 2, inorganic materials: Grade A flame-resistant materials are divided into three classes and two kinds of materials.

- Q: I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

- Q: Who knows that among refractory materials, insulation boards from which refractory material industry is superior in quality?

- Using high temperature insulation material during casting process .In the molding, assembly the insulation?board on the ingot head or install heat insulation cap . There are three ways to install the molded steel insulation board and install insulation?board on at the head of the ingot, namely, clamping, nail fixation and mosaic technique.Compared with clay-based liner, the use of insulating board will improve high steel billet rate up to about 5% to 10%.

- Q: What's the difference of fire-resistant material's density, specific gravity and bulk specific gravity?

- glass

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: The performance of refractory material

- As for easticity modulus, you can serach for information on the Internet or specialized books.

- Q: What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material. And those we usually see are the mineral?cotton and glass wool, with its refractory temperature lower than the rock wool's. Rock wool board is now mainly used in wall insulation, which is a level A fire insulation material.

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords