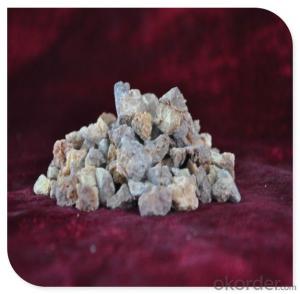

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory 90percent MgO Dead Burnt Magnesite Price

Dead Burned Magnesite

Description

Dead Burnt Magnesite is produced in the Rotary Kiln by sintering raw magnesite at a controlled temperature of 1750 degree centigrade and its chemically inactive. Dead Burnt Magnesite is consume almost exclusively in the production of Refractory Field.

Dead Burnt Magnesia Application:

1. Refractory Industry for manufacture of Basic Refractory Bricks .

2. Manufacture of Ramming Mass composition, Fettling material and Magnesite Mortar.

3. It is used in SLAG beneficialness and in SLAG splashing in Arc Furnaces.

4. It is also used as a coating material in Steel Industry.

MgO ≥ | CaO ≤ | SiO2 ≤ | L.O.I. ≤ | BD ≥ g/cm3 | size mm | |

VT-MGO-DBM 87 | 87 | 2.2 | 7.0 | 0.5 | 3.1 | according to the requirement of customer |

VT-MGO-DBM 90 | 90 | 2.2 | 5.0 | 0.3 | 3.15 | |

VT-MGO-DBM 91 | 91 | 2.0 | 4.5 | 0.3 | 3.18 | |

VT-MGO-DBM 92 | 92 | 1.8 | 4.0 | 0.3 | 3.18 | |

VT-MGO-DBM 93 | 93 | 1.6 | 3.5 | 0.3 | 3.18 |

Our Lab

Our service

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: The mechanism and function of antioxidants in carbon containing composite refractories are briefly described.

- With the advantages of carbon refractories especially excellent slag resistance and high heat stability, but graphite under high temperature oxidation, in order to improve the oxidation resistance of carbon composite refractory materials, often adding a small amount of antioxidants, to improve the oxidation resistance of carbon composite refractories. Antioxidant additives commonly used in metal powder, silicon powder, magnesium powder, silicon carbide powder and so on.

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: What are the applications of refractory busway?

- Fire-resisting busway can be applied to power transmission and distribution systems with rated voltage below 690V, rated current is 250-5000A and frequency is 50-60Hz. After years of testing and industrial electrical operation, its electrical resistance, fire resistance, metal structural property have reached the advanced level in China.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: How to make fire resistant materials for building stoves

- Why Qianjun game protected mode can attack the foreign baby call

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- The national standard for fireproof door of level B is 1.5h, which must be achieved. The data GB12955-2008 means that the door leaf of raw material is 0.8mm-1.2mm in thickness and door frame is 1.2mm-1.5mm in thickness. And other metal melting temperature shall not be less than 950℃, the duration of fire resistance shall not be less than 0.9 hours. Fire department will check and accept based on the manufacturer's inspection report, so you have to refer to manufacturer's inspection report if you want to know more in detail.

- Q: What refractories can withstand high temperature above 2100 degrees?

- But the price is more expensive, while the insulation performance is not as good as common materials. Is there a material that can withstand 2100 ℃? Currently, the long-term use temperature of the best refractory bricks is about at 1800 ℃, while materilas that can withstand a temperature of 2100 ℃ are relatively rare in the production.

- Q: How many external wall thermal insulation fireproof material are there

- External wall thermal insulation materials are generally divided by the burning grade, into class A, B grade. Grade A is non combustible material, grade B is combustible material. Class A which can be divided into thermal insulation mortar, bakelite plate, rock wool plate, foam cement plate etc.. Insulation mortar is relatively good, easy for construction, convenient, low cost, but its production process is too simple, so it is prone to fake. I recommend you to find a large manufacturing factory that posses complete procedure, for example, provincial production record, the provincial use record, municipal record, tset report at or above the provincial level, state fire proof report, design drawings of office building. product will not be safe if there is a lack of any of these documents. Burning level for henolic is uaually class B, but class A2 can be reached if a thin layer of mortar is applied on the suface,(A1 is the highest level of fire safety),intensity of phenolic is not high, finger pressing will leave a pit on it. if classified according to kilogram, raw material differs greatly every 10 kilogram. Rock wool is also classified by kilogram, general using 150kg wool. Rock wool are now comprounded with average strength. It will easily absorb water, having trouble applying paints. Foam cement strength is not high, easy to absorb water, It is not resistant to falling. It costs low, only used unless little profit can be made, Do not use it if worrying accidents would happen. These materials can be firstly burned, The palce the sample into water to see if it will dufuse at last. External wall should stand up to wind and rain. In terms of thermal insulation, they are almost the same, shows little differences on design thickness.

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- There are many Dalian thermal insulation materials, which can be divided into organic and inorganic thermal insulation materials. Materials include inorganic thermal insulation materials, polyfoam, mineral wool products, foam glass, expanded perlite insulation products, gelatine powder EPS grain heat insulating slurry, sprayed mineral wool, thermal insulation product of foam cements, and vacuum thermal insulation board.

- Q: Where is the development of refractory industry?

- The rapid development of continuous casting technology of its related @ China @4 honing refractories develop and increase in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

Send your message to us

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords