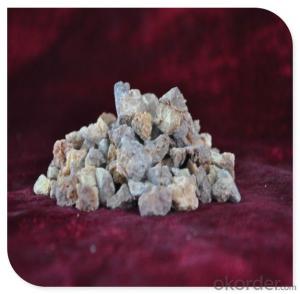

Raw Materials for Refractory:Dead Burnt Magnesite MgO 97%

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Item | MgO | SiO2 | CaO | LOI | B.D.(g/cm3) |

| DBM-97 | 97 | 0.7 | 1.4 | 0.2 | 3.2 |

| DBM-96 | 96 | 1.5 | 1.5 | 0.2 | 3.2 |

| DBM-95 | 95 | 2.2 | 1.6 | 0.3 | 3.2 |

| DBM-94 | 94 | 3 | 1.6 | 0.3 | 3.2 |

| DBM-93 | 93 | 3.5 | 1.6 | 0.3 | 3.2 |

| DBM-92 | 92 | 4 | 1.6 | 0.3 | 3.18 |

| DBM-92 | 92 | 4 | 1.6 | 0.3 | 3.18 |

| DBM-91 | 91 | 4.5 | 1.6 | 0.3 | 3.18 |

| DBM-90 | 90 | 4.8 | 2 | 0.3 | 3.18 |

| DBM-87 | 87 | 7 | 2.2 | 0.3 | 3.2 |

Dead burned magnesite- DBM-is produced using selected natural magnesite that is purified and is calcined in a shaft kiln.The final product is used for electric furnacefloors and furnace liner tamping.

Main products level :

0-1mm;1-3mm;3-5mm;0-10mm;0-30mm

50 to 325mesh (90% through)

Product feature:

high temperature performance and high-density, strong anti-permeability ability and easy to rapid sintering, very thin sintered layer,good thermal shock stability, strong slag-resistance, long service life and so on.

Product function:

Apply to the construction of bottom and wall of all kinds steel making electric arc furnace and ferroalloy smelting furnace for hot charging of hot metal and second hand steel

Product usage:

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect .

Product Advantage:

Our factory produce the products of the Dead-burned magnesite are selected natural magnesite, it is produced by mine-selecting, purifying, calcimine in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, electric furnace bottom and furnace's lining tamping.

- Q: Refractory material, refractory brick

- High alumina brick is commonly used in high aluminum, LZ-75, LZ-65 and LZ-55, as well as high alumina brick for blast furnace, high alumina brick for hot blast furnace, and low creep high alumina brick

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: How much is the duration of fire resistance of the porous brick shale?

- This is really a simple question. The temperature should be limited within 1050℃, or it will be scorched. I think 980℃would be acceptable.

- Q: What are the chemical composition of refractory cement?

- Calcium aluminate prepared by calcining as the main component. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement.

- Q: which kind of refractory is commonly used in the industry

- Like silicon, magnesium calcium and metallurgy refractories, glass, silicon, etc., knowing the basic materials, and the businesses are not the same. I suggest that you can buy the refractory book to read.. Others include zircon, shapeless refractory material and so many other cement, such as magnesia, high alumina,ect.. Iron making is using the acidity material, continuous casting is using the clay, nonferrous metals and other types of more complex hot-press charcoal; steel making is using the alkaline, magnesium chrome, magnesium carbon, and clay,etc..

- Q: What are the construction fire-proof materials?

- 1. fire?retardant?coating 2. fireproof?panel 3. fire proof and sealing material 4. flame resisting decorative materials 5. Green fire prevention materials

- Q: Does anyone know the fire endurance of steel stud partition?

- Indeed ① Dragon Brand gypsum board fire-resistant partition: Its fireproofing extreme time is 4 hours, suitable for firewalls of a variety of public buildings, public exit passageway and other partitions, which meets the first level of fire protection standard ② fireproofing and pressure-resistant partition: Refers to the partition which can withstand momentary gas shocks of over 1200pa , mianly used for the room partition with inert gas fire-fighting needs, such as equipment rooms. The pressure-resistant degree of fireproofing and pressure-resistant partition of Beixin Building Materials can be up to 4800Pa, especially suitable for high-rise fireproofing.

- Q: Who can tell me the properties and classification of insulating refractories?

- It is the chemical method. The chemical reaction in the brick making process to produce gas and method for obtaining a porous brick. Usually use chemical reactions such as carbonate and acid, metal powder with acid, caustic and aluminum. Chemical reactions can be used must be relatively slow and can control or mechanical disturbance will disappear bubble in an injection mold. If the reaction is too fast, adding inhibitors such as hydrogen peroxide and manganese dioxide. The fine powder material slurry mixed with reactant bubbles to obtain stable foam slurry injection model, after drying the firing. This method of making pure oxide insulating refractory products, its porosity can reach 55% ~ 75%.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- The fire-resisting time of class B fire proof door is 1h and thickness of door can't be lower than 45mm.

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite MgO 97%

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords