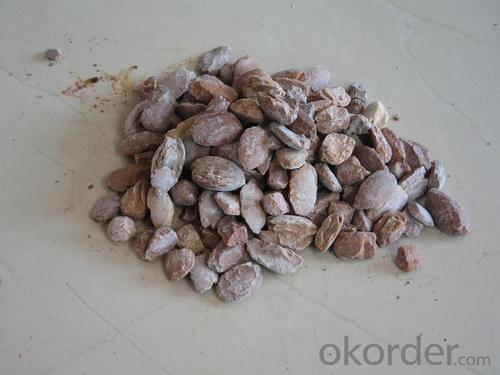

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Dead Burnt Magnesite (DBM):

Dead Burnt Magnesite is selected from natural magnesite, calcined temperature and the shaft kiln. It is the material of ordinary magnesia bricks, shaped and unshaped refractory products.

Specifications of Dead Burnt Magnesite (DBM):

Specification(%) | ||||||

Brand |

MgO min. |

LOI max. |

SiO2 max. |

CaO max. |

Fe2O3+Al2O3 max. |

B.D.G/cm3 min. |

DBM90 |

90.00 |

1.00 |

4.50 |

2.50 |

3.00 |

3.1 |

DBM-95 |

95.00 |

0.30 |

3.00 |

2.00 |

1.30 |

3.15 |

DBM-97 |

97.00 |

0.20 |

0.7 |

1.3 |

0.90 |

3.25 |

DBM-972 |

97.2 |

0.2 |

0.6 |

1.3 |

0.9 |

3.27 |

DBM975 |

97.5 |

0.1 |

0.6 |

1.2 |

0.8 |

3.28 |

Packaging & Delivery of Dead Burnt Magnesite / DBM:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications:

1.Mainly used in processing raw materials of different magnesia refractory,

2. the production of steel lining the bottom and ramming mixes;

3. the raw materials of magnesia brick and magnesia-chrome brick;

4.used electric steel making furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of grade A fire resistance rolling shutter doors should be no less than three hours. Fire doors can be divided into A, B and C grades according to their fire endurance which should be no less than 1.20 h, 0.90 h and 0.60h respectively. Places where are difficult to set fire-proof bulkheads can use fire resisting shutters as partitions of fire?compartments. The fire endurance of fire resisting shutters that include unexposed surface temperature rise as judging condition should be no less than 3 h. Fire resisting shutters that exclude unexposed surface temperature rise as judging condition should set up independent protection of closed automatic water spray system on both sides of shutters, and the duration of water spray system should be no less than 3.0 h.

- Q: what is the grading standards of external wall thermal insulation materials?

- external wall thermal insulation materials are divided according to Fire rating: 1, the combustion performance of insulation materials rates A. inorganic fiber spray coating, glass wool, foam glass, foamed ceramic , rock wool, foam cement, obturator perlite 2, the combustion performance of insulation materials rates B1: Extruded polystyrene board (XPS)after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polyphenyl granule.3, combustion performance of insulation material rates B2. Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: How about the prospect of refractory material?

- Area depends the market. Resource-based industry

- Q: What are the applications of refractory?

- Refractory materials are widely used in iron and steel smelting , glass, cement kilns, non-ferrous metal metallurgy, environmental protection, and chemical, etc. For example: For a car of 1.5 tons, do you you know how much refractory it use? The answer is: To produce top hat or other steel products, glass for vehicle windows, nonferrous metals kile aluminum and copper, plastic products of the body all needs refractory. A car of 1.5 tons needs to consume a total of 10Kg refractories.

- Q: Can anyone say something about the curtain wall fire-proof material key sealing point?

- When sealing the gaps between glass?curtain?wall and floors of all layers and the outer edge of the partition with rock wool or mineral wool, its thickness should not be less than 100mm and should be filled densely; Rock wool or mineral wool for horizontal smoke prevention zone between floors should use galvanized steel sheet whose thickness is not less than 1.5mm to support; The gaps between supporting plate, major structure, curtain wall structure and supporting plate should be filled with fire-resistant glass, whose fire endurance should meet the design requirements. Fire-resistant glass for curtain wall are mainly include monolithic fire-resistant glass as well as the hollow glass and laminated glass made by monolithic fire-resistant glass.

- Q: What defect does fused cast refractories have ?

- The impact on the quality of glass is mainly the defects that eroded down refractory materials mixed in the glass, thus being prodeced of grass products. Defects are mainly foreign body defects such as sand, knot and wave reinforcement.

- Q: Who knows about ranking rules of fireproofing thermal insulation materials for exterior wall?

- You can try the following way to give a brief introduction of the fire?rating classification of external wall thermal insulation materials. 1. the building materials are divided into following categories in terms of combustion performance according to the national standard of GB8624-97. A-level: Incombustible building material: materials almost don't burn. B1-level: nonflammable building material: these materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building material: combustible building materials can play a certain role in flame resistance. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden column, timber roof truss and timber beam as well as stairs. B3-level: Inflammable building material: Inflammable building materials are highly flammable with no flame retardant ability. The fire risk is high. 2.The exterior wall thermal insulation materials can be classified according to fire rating. 1). Insulation materials with A-level combustion performance: rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2). The insulation materials with B1-level combustion performance: specially-treated extruded polystyrene board(XPS)/ specially-treated polyurethane(PU), phenolic aldehydegelatine powder polyphenyl granule,etc. 3). Insulation materials with B2-level combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc.

- Q: How long is the fire endurance of fire resistant rolling shutter door?

- According to the new national standards GB_12955-2008 for fire doors from January 1, 2009, fire doors are classified acoording to thermal insulation fireproof door(A),part heat insulation fireproof door(B) and non thermal insulation fireproof door(C), rather than thermal insulation fireproof door. At the same time, the original fire endurances of class A, B and C fire doors are adjusted to 1.5h, 1.0h and 0.5h respectively. So, GB is 1.5h

- Q: Are the rubber insulation materials are refractory materials?

- It's not.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords