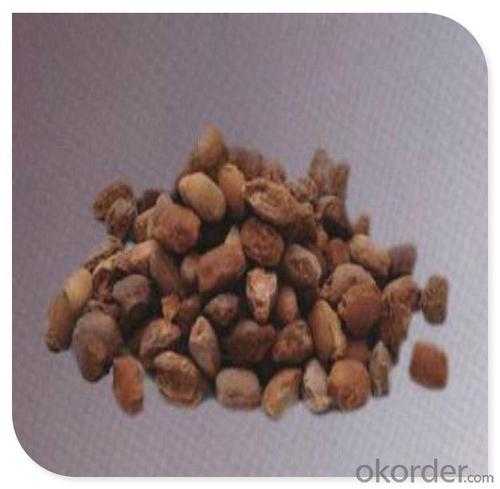

Raw Materials for Refractory - Dead Burned Magnesite/DBM/Dead Burnt Magnesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dead Burned Magnesite/DBM/Dead Burnt Magnesia

Specifications

1.good sintered, calcination uniform,

2.high purity, activity, and uniform chemical composition,

3. quality and stability

MgO ≥ | CaO ≤ | SiO2 ≤ | L.O.I. ≤ | BD ≥ g/cm3 | size mm | |

RGMS-87 | 87 | 2.2 | 7.0 | 0.5 | 3.1 | according to the requirement of customer |

RGMS-90 | 90 | 2.2 | 5.0 | 0.3 | 3.15 | |

RGMS-91 | 91 | 2.0 | 4.5 | 0.3 | 3.18 | |

RGMS-92 | 92 | 1.8 | 4.0 | 0.3 | 3.18 | |

RGMS-93 | 93 | 1.6 | 3.5 | 0.3 | 3.18 |

Our Lab

Our Service:

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- China is mainly used in honing, maybe I face all doubt you forget who may waste cheap no taste who cheated you don't mind set back easily stripped of a planet in the comfort of your brow you open your mouth and then grow the universe to my hand behind you let you spend what a fragile Oh maybe I face all abandoned about half past three in the morning wake up to drink a cup of soda rather baffling weary belch a bubble the tiny uneasy, and perhaps two of us Butterfly

- Q: Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- There is no difference between them because they are the coating with the same texture. But generally galvanized treatment is not necessarily needed for brushing fireproof coating. Fireproof coating and galvanized surface have relatively poor bond strength. So it is advisable to bursh trasitional lacquer or micaceous iron on galvanized surface.

- Q: How to classify the grade of wall fireproof and thermal inuslation matertial?

- External wall thermal insulation materials are mainly divided into grade A, grade B1, grade B2 and grade B3. In accordance with the current "Combustion Performance Classification Method of Building Materials", grade A thermal insulation material is incombustible?material and belongs to inorganic heat preservation material. However, grade A thermal insulation material is few in terms of the current market. There are only JETCO YT inorganic active wall thermal insulation material, glass wool, rock wool board, foam glass, vitrified micro bead and grade A fireproofing thermal insulation board. However, compared with grade A thermal insulation material, the more welcomed by the market is the organic insulation materials. Thermal insulation material that is determined as grade B is divided into three levels. Grade B1 is grade is flame retardant. Grade B2 is combustible. Grade B3 is flammable.

- Q: What is the role of the vermiculite fireproof material?

- Apart from inflaming retarding, the materials covered with vermiculite has a lot of advantages including anti rust, waterproof, anticorrosive, wear-resisting, heat-resisting and the coating is armed with toughness, colorability, adhesiveness, fast-drying and luster.

- Q: Which schools are the best schools in the world for learning knowledge about refractories?

- If you search on a worldwide scale, I might say you are ambitious!!! This major becomes an unpopular one and you must have to embark on graduate and PhD to specialize in it provided that you want to go abroad for further study. Wuhan University of Science and Technology may be the best school in this field with its close relatinship with many refractory manufacture factories across the country. Henan University of Science and Technology is also advisable in terms of this major, which probably promise you a job. Other universities in this regard are not quite familiar to me. You raised these questions, which shows that you are a layman to this major or not quite familiar with this major. If you have any questions, you can resort to me if I can.

- Q: what's the varieties of thermal insulation material with A level fire?rating?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- If the outer packing is made of solid wood, it must be fumigated! If it is not solid wood, you can do without!

- Q: which is better as household fireproof material ?

- If it is from the perspective of fire rating inorganic active insulation material for wall thermal, cement foam insulation board, glass beads of insulation movitrified?micro bead?thermal insulation?mortar, rock wool board, glass wool board, ect.. thermal insulation material are Class A fireproofing, polyphenyl board, extruded sheet, phenolic foam board, Polyurethane board, ect..belong to B1 level fireproofing, if it is used for external wall thermal insulation in decorative board, then rock wool board is more often used.

- Q: What's the commonly used refractory material for ladle?

- 1. According to the refractoriness, it can be classified as follows: common refractory: 1580℃ ~ 1770℃; high grade refractory: 1770℃ ~ 2000℃; superrefractory: 2000 ℃; 2. According to the shape and demension of the product, it can be classified as follows: standard form : 230mm×113mm ×65mm of no more than four measuring scale, (demension ratio) Max: Min

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- There are many Dalian thermal insulation materials, which can be divided into organic and inorganic thermal insulation materials. Materials include inorganic thermal insulation materials, polyfoam, mineral wool products, foam glass, expanded perlite insulation products, gelatine powder EPS grain heat insulating slurry, sprayed mineral wool, thermal insulation product of foam cements, and vacuum thermal insulation board.

Send your message to us

Raw Materials for Refractory - Dead Burned Magnesite/DBM/Dead Burnt Magnesia

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords