Raw Materials for Refractory - Best Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Best Calcined Bauxite for Refractory Raw Materials

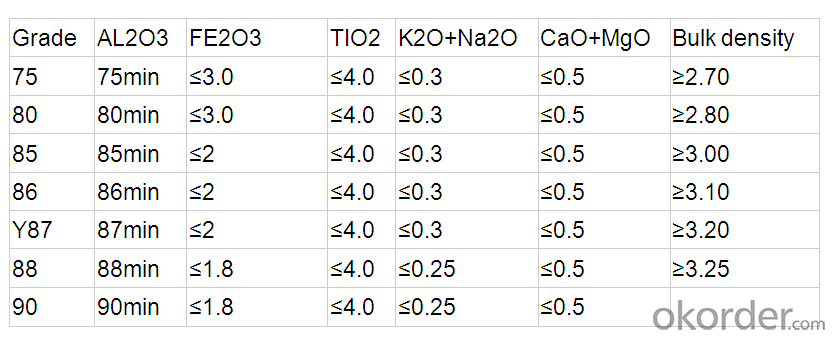

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What is the upper temperature limit for refractory materials?

- The key depends on what refractories you use

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: Is the ball mill used in production of refractories?

- It depends on what refractory you produce.

- Q: What are the insulation fireproofing materials?

- Insulated shoes, insulated gloves, tape (cloth, plastic, as well as waterproof) yellow wax tube, mouth care, fireproof (ie asbestos cloth is sold by jin) there is pressure-caps black tape, waterproof tape ,casing. There are glass fiber needle felt is widely used in electrical, chemical, construction, transportation, automotive and other industries interlayer insulation and silencer system, and used as an insulating fireproof material.

- Q: What are the main components of refractory cement?

- SiO powder is often used. Ultra-fine powder refers to less than 1 / zm particles which are made by hydrolysis of ethyl silicate or made from recycled dust in the smelting process of ferro-silicon alloy. Non-cement castable refractory are castable refractory material which contains no cement instead it relies on the coagulation and combination by adding ultra-fine powder or sol (see refractory castable), and it is an amorphous material with high activity. Silica sol is made through Ion-exchange of sodium silicate after Na ions are removed. The easiest method is to prepare by reaction of aluminum metal with hydrochloric acid or alchlor. It is a thermodynamically unstable system which has certain requirements for ultra-fine powder and sol. It is different from non-cement refractory castable, Cr2zrOz and etc. It has low impurity content, and can bond with itself, so it has good binding strength. Ultrafine powder used in non-cement castables are SiO2, Al2O3, Cr2zrOz, etc. Such recycled SiO2 powder has an average particle diameter of 0.5 pm, therefore when adding the gelling agent (electrolyte), it can coagulate and give the products some bonding strength. Non-cement castable refractory is made up of refractory aggregate and powder and it is round. Since the use of superfine powder or sol as binder. The size of sol particles are of 0.1 ~ 1 m. Non-cement refractory castable takes oxide or synthetic compound ultra-fine powder or oxide sol-gel which is similar to the chemical composition of material in tungsten castable. There are several ways to prepare alumina sol. The sol used are mainly alumina oxide and silica sol. The surface area is large, and it helps to improve high-temperature structural strength. Non-cement castable refractories rely on oxide ultra-fine powder or sol to coagulate and combinate. It is a refractory castable (also known as chemical bonding castable) which uses chemical binder instead of cement for combination.

- Q: Who knows about the fire endurance of grade C fire doors?

- It can be classified according to the fire endurance and thermal insulation performance: The fire endurance of grade A fire doors is not less than 1.5 hours; that of grade B fire doors is not less than 1.0 hours; and that of grade C fire doors is not less than 0.5 hours. I hope my answer can help you.

- Q: which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q: What material is used for making refractory stone bowl?

- Stone pot, to make it easy, is pot made of stone. Stone pot is carved from high-quality natural refractory stone with a professional way. It has attractive and diverse appearance, and it is hard, heat fast, not stick food and the cooked food is attractive and delicious. And it is rich in a variety of trace elements which is beneficial to the human body. High quality

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory includes metallurgical auxiliary materials.

- Q: Where is the development of refractory industry?

- Continuous casting system varieties used in refractory materials include: (1) ladle refractories -- ladle lining, permanent lining, ventilation components; (2) tundish refractories -- linings and coatings, insulation board, cover; (3) functional refractories -- non oxidation casting with long nozzle, immersion nozzle, stopper, sliding gate; (4) purifying molten steel with ceramic purifier, slag dam, alkaline coating and horizontal continuous casting for separating ring gate, etc..

Send your message to us

Raw Materials for Refractory - Best Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords