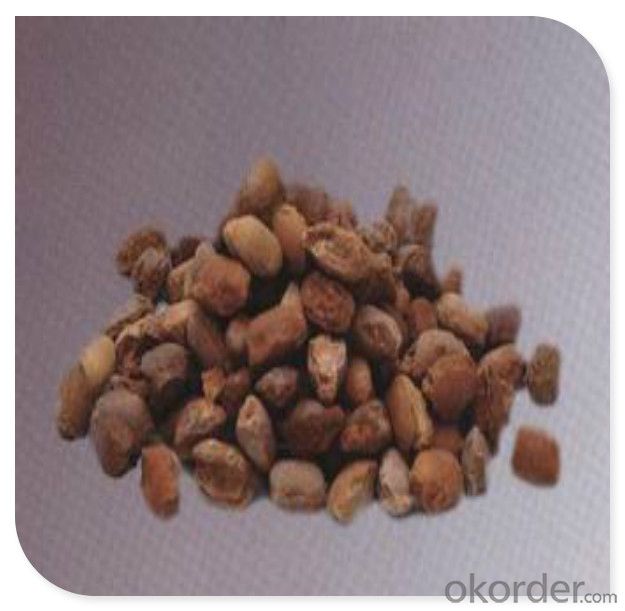

Raw Materials for Refractory - Dead-Burned Magnesite (Dead Burnt Magnesite)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dead-burned Magnesiten Dead Burnt Magnesite

Specifications:

1.High purity Large crystal grain Compact structure

2.Strong resistance to slag material

3.Good thermal shock resistance

Magnesium Oxide is used in a number of industrial applications including: | |

Abrasives | As a binder in grinding wheels |

Animal feed supplement | Source of magnesium ions for chickens, cattle and other animals |

Boiler (oil-fired) additives | Material that is easily removed; reduced corrosion of steel pipes holding steam as well as sulfur emissions into the environment |

Boiler feedwater treatment | Reduces iron, silica and solids |

Chemicals | Starting point for the production of other magnesium salts such as sulfate and nitrate |

Coatings | Pigment extender in paint and varnish |

Construction | Basic ingredient of oxychloride cements used for flooring, wallboard, fiber board, and tile |

Electrical | Semi-conductors; heating elements insulating filler between wire and outer sheath |

Fertilizers | Source of essential magnesium for plant nutrition |

Foundries | Catalyst and water acceptor in shell molding |

Glass manufacture | Ingredient for specialty, scientific and decorative glassware and fiberglass |

Insulation | Light, flexible mats for insulating pipes |

Lubricating oils | Additive to neutralize acids |

Pharmaceuticals | Special grades of magnesium hydroxide, oxide and carbonate are used in antacids, cosmetics, toothpaste, and ointments |

Plastics manufacture | Filler, acid acceptor, thickener catalyst and pigment extender |

Refractory and ceramics | Basic ingredient in product formulations for the stee industry |

Rubber compounding | Filler, acid acceptor, anti-scorch ingredient, curing aid, pigment |

Steel industry | Annealing process; coating for grain-oriented silicon steel used in electrical transformers |

Sugar refining | Reduces scale build-up when used in juice clarification and precipitation |

Sulfite wood pulping | Source of base for cooking liquors |

Uranium, gallium & boron | Precipitation initiator by acid neutralization processing |

Wastewater treatment | Acid stream neutralizer; precipitates heavy metals |

Our Lab

Our Service:

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- The cut is relatively transparent if you jam, we have also used silicon manganese alloy

- Q: Does anyone know the difference between refractory and thermal insulation material?

- The main difference between insulation bricks and refractory bricks are as follows: 1. Insulation effect The heat conductivity cofficient of insulation bricks is usually 0.2-0.4 (average temperature of 350 ± 25 ℃) w / mk while the heat conductivity coefficient of refractory bricks is 1.0 (average temperature of 350 ± 25 ℃) w / mk or more. Thus it can be seen that the insulation effect of insulation bricks is much better than that of refractory bricks. 2. Refractoriness The refractoriness of insulation bricks is generally below 1,400 degrees centigrade while the refractoriness of refractory bricks is above 1,400 degrees centigrade. 3. Density Insulation bricks are generally light-weight insulation material, and the density is generally 0.8-1.0g / cm3. But the density of refractory bricks is above 2.0g / cm3.

- Q: what's the varieties of fire-proof?sealing?material?

- ATD-AB, organic fire-proof caulking, fire retardant bag, fire retardant net, fire retardant ring, fire barrier wrap, fireproofing sealing strip, flexibility fireproofing coiled material, fireproof glue, etc., fireproofing sealing materials currently on the market can be divided into two types, one is the traditional type: flexible organic caulking, WXY-II, fire retardant bag, fire?bulkhead, cable refractory coating; there are some new materials used in large-scale projects: fireproofing coating board system (fireproofing coating board, intumescent fireproof sealing tape, elastic fireproof sealant, Waterborne Fire-retardant Coating), fire retardant module system (fire retardant module, sealing gum, cable refractory coating), fireproofing plaster system (fireproofing plaster, sealing gum, cable refractory coating).

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: How to distinguish the fire?rating of rubber and plastic thermal insulation material?

- According to GB 8624-2006 "building materials and combustion products classification", the division of the material's combustion performance grade is changed from five levels of level A (homogeneous material), A (composite sandwich material), B1, B2 and B3 to seven levels of A1 , A2, B, C, D, E and F or A1f1, A2f1, Bf1, Cf1, Df1, ef1 and Ff1 or A1L, A2L, BL, CL, DL, EL and FL . The level B1 rubber and plastic fireproof and thermal inuslation matertial is the best, but the most commonly used one is level B2. Hope it will help you.

- Q: Which industry does refractory belong to?

- It belongs to inorganic refractory: Ceramic refractory bricks (used in steel-making furnaces) There is also organic polymer in heavy industry: Halogen-containing and halogen-free It belongs to construction industry.

- Q: Which industry does the metallurgy and thermal insulating and refractory material belong to?

- According to "New Economic Industrial Classification", the metallurgy and the thermal insulation refractory matter belong to C category. The manufacturing industry has 30 categories. The non-metallic mineral products industry has 303 classes. The production of building materials of tiles, stones, ect. refers to clay, ceramic tile production, building stone processing, building materials produced by wastes or drogs and subcategories 3035 produced by other building materials. The manufacture of thermal and acoustic insulation materials refers to the manufactuer of mineral insulation materials and other products, like rock wool, mineral?cotton, expanded perlite and expanded vermiculite used for thermal insulation and sound insulation, but it does not include the production of 3039 subcategories, like asbestos thermal insulation and sound insulation materials, and other construction materials.

- Q: How long is the fire-resistant time of fireproof wooden door?

- fire endurance class A (1.5 hours), class B (1.0 hours), class C (0.5 hours).

- Q: What kind of refractory decorative board has good quality?

- The unique design and personalized style of well-known brand "transit" rank highest in the field of domestic refractory slab. It is one of the largest manufacturers of high pressure decorating refractory slab in China. The production base covers an area of 40,000 square meters and the annual output is 4 million. It passes the test of Quality Supervision and Inspection Center of National Fire Protection Building Material and ISO9002 certification. The products pass international standards such as 4586, the United States NEMA and so on.

- Q: What kinds of refractory materials that can resist 3,000 Celsius degree?

- I think that graphite is the only one.

Send your message to us

Raw Materials for Refractory - Dead-Burned Magnesite (Dead Burnt Magnesite)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords