Ral 9014 PPGI for Exporting Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Ral 9014 PPGI for Exporting

Description of Ral 9014 PPGI for Exporting

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Ral 9014 PPGI for Exporting

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

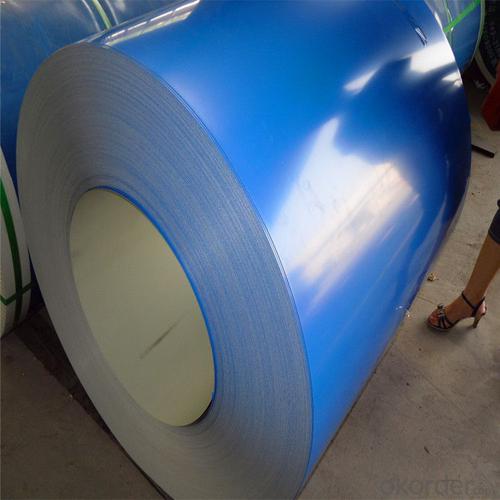

Products Show of Ral 9014 PPGI for Exporting

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the main applications of special steel in the defense aircraft?

- Special steel is used in defense aircraft for a variety of critical applications. Some of the main applications include structural components, engine components, and armor. Special steel provides high strength and durability, allowing it to withstand extreme conditions and protect the aircraft from impacts and ballistic threats. It also offers excellent heat resistance, corrosion resistance, and fatigue resistance, making it ideal for use in critical areas where safety and reliability are paramount.

- Q: How is special steel used in the construction manufacturing process?

- Special steel is commonly used in the construction manufacturing process due to its unique properties such as high strength, durability, and resistance to corrosion. It is used for various applications, including structural components, reinforcement bars, and fasteners. Special steel enhances the overall structural integrity of buildings, bridges, and other construction projects, ensuring their longevity and safety.

- Q: Can special steel be used for food processing equipment?

- Yes, special steel can be used for food processing equipment. Special steel, such as stainless steel, is often preferred in the food industry due to its hygienic properties, resistance to corrosion, and durability. It is commonly used in various food processing equipment such as mixers, slicers, cutters, and storage tanks to ensure safe and efficient food production.

- Q: How does special steel contribute to the defense equipment industry?

- Special steel plays a crucial role in the defense equipment industry by offering superior strength, durability, and performance characteristics that are essential for producing high-quality military equipment. This type of steel is specifically engineered to meet the demanding requirements of defense applications, ensuring the safety and effectiveness of military personnel and operations. One of the key contributions of special steel to the defense equipment industry is its ability to withstand extreme conditions and environments. Military equipment often operates in harsh conditions, including extreme temperatures, high pressures, corrosive environments, and impact forces. Special steel is designed to maintain its structural integrity and performance under these challenging conditions, providing a reliable and long-lasting solution for defense equipment. Moreover, special steel offers exceptional strength and toughness, making it ideal for manufacturing armored vehicles, tanks, and military aircraft. It provides a high level of protection against ballistic threats and can withstand projectile impacts and explosions. The use of special steel in defense equipment ensures the safety of military personnel and enhances their survivability in combat situations. Additionally, special steel is essential for the production of cutting-edge weaponry and munitions. It is used in the manufacturing of firearms, missiles, and artillery systems due to its excellent mechanical properties and ability to withstand high pressures. Special steel also enables precision engineering, ensuring the accuracy and reliability of military firearms and projectiles. Furthermore, special steel contributes to the defense equipment industry by supporting technological advancements. As technology continues to evolve, the defense sector requires materials that can meet the demands of modern warfare. Special steel can be tailored and optimized to meet specific performance requirements, allowing for the development of advanced defense systems such as stealth technology, electronic warfare, and precision-guided munitions. In conclusion, special steel plays a pivotal role in the defense equipment industry by providing the necessary strength, durability, and performance characteristics required for military applications. It ensures the safety and effectiveness of defense personnel and equipment, withstands extreme conditions, enables the production of advanced weaponry, and supports technological advancements in the defense sector.

- Q: Can special steel be used in the production of medical implants?

- Yes, special steel can be used in the production of medical implants. Special steels, such as stainless steel, titanium alloy, and cobalt-chromium alloy, possess specific properties that make them suitable for use in medical applications. These steels are biocompatible, meaning they do not cause adverse reactions or toxicity in the human body. They have high strength, corrosion resistance, and can withstand the harsh conditions inside the human body. Special steels can be used to manufacture various medical implants, including orthopedic implants like hip and knee replacements, dental implants, cardiac stents, and surgical instruments. The use of special steel in medical implants ensures durability, longevity, and biocompatibility, making them a reliable choice for improving patients' quality of life.

- Q: What are the properties of special steel?

- Special steel has several unique properties that make it highly desirable in various industries. Firstly, it possesses exceptional strength and durability, allowing it to withstand high levels of stress, pressure, and temperature. This property makes it suitable for applications in construction, automotive, and aerospace sectors where strength and reliability are crucial. Additionally, special steel offers excellent corrosion resistance, ensuring its longevity even in harsh environments. It is also known for its excellent machinability, weldability, and formability, making it easy to work with and shape into desired forms. Furthermore, special steel exhibits good magnetic properties, making it ideal for use in electrical components and magnetic devices. Overall, the properties of special steel make it a versatile material that can be customized for specific applications, offering exceptional performance and reliability.

- Q: How is special steel used in toolmaking?

- Special steel is widely used in toolmaking due to its exceptional properties that make it highly suitable for creating durable and high-performance tools. Toolmaking involves the manufacturing of various tools such as drills, saws, cutting tools, dies, and molds, among others. Special steel is utilized in toolmaking to ensure that these tools possess the necessary strength, hardness, toughness, and wear resistance required for their intended applications. One of the primary advantages of special steel in toolmaking is its high strength. Special steel is alloyed with elements such as chromium, molybdenum, vanadium, and tungsten, which enhance its strength and hardness. This enables the tools to withstand heavy loads, resist deformation, and maintain their structural integrity even under extreme working conditions. In addition to strength, special steel also exhibits excellent hardness. Tools made from special steel undergo heat treatment processes such as quenching and tempering to achieve the desired hardness level. This hardness is crucial for toolmaking as it enables the tools to efficiently cut, drill, or shape various materials without getting damaged or worn out easily. Furthermore, special steel possesses exceptional toughness. Toughness refers to a material's ability to absorb energy and resist cracking or fracturing. Tools made from special steel can withstand impact and heavy loads, ensuring that they do not break or chip easily during use. This is particularly important in toolmaking as tools often encounter high-stress situations where toughness is vital to prevent premature failure. Another significant advantage of special steel in toolmaking is its excellent wear resistance. Tools are subjected to constant friction, abrasion, and contact with hard materials, leading to wear and tear. Special steel is specifically designed to resist wear, enabling the tools to maintain their cutting or shaping abilities over extended periods. This not only prolongs the tool's lifespan but also ensures consistent performance and high-quality output. Special steel is also known for its corrosion resistance, which is beneficial in toolmaking, especially when working with corrosive materials or in harsh environments. The inclusion of certain elements like chromium in special steel enhances its resistance to corrosion, preventing rust and deterioration of the tools. In conclusion, special steel plays a crucial role in toolmaking by providing the necessary strength, hardness, toughness, wear resistance, and corrosion resistance. These properties enable the tools to perform effectively and efficiently, ensuring durability and longevity. Whether it is for cutting, drilling, shaping, or molding, special steel is an essential material in the production of high-quality tools that meet the demands of various industries.

- Q: How is special steel protected against corrosion?

- Special steel is protected against corrosion through various methods such as coating it with corrosion-resistant materials like zinc, nickel, or chromium, using cathodic protection techniques, applying protective paints or sealants, and employing proper maintenance practices like regular cleaning and inspections.

- Q: How does special steel contribute to the railway industry?

- Special steel plays a crucial role in the railway industry by contributing to the development and maintenance of efficient and reliable rail systems. The unique properties of special steel, such as high strength, durability, and resistance to wear and tear, make it an ideal material for various components and structures within the railway infrastructure. One of the key areas where special steel contributes to the railway industry is in the manufacturing of rails. Special steel rails are designed to withstand heavy loads and intense usage, ensuring the safe and smooth movement of trains. These rails are highly resistant to wear, fatigue, and deformation, resulting in longer service life and reduced maintenance costs. Additionally, special steel is used in the manufacturing of wheelsets, which are critical components of trains. The high strength and durability of special steel make it ideal for wheelset production, ensuring reliable performance and minimizing the risk of derailments. The use of special steel in wheelsets also contributes to increased operational efficiency, as it reduces friction and enhances energy transmission, leading to improved fuel economy and reduced environmental impact. Furthermore, special steel is utilized in the construction of bridges, tunnels, and other infrastructure elements within the railway network. These structures must withstand heavy loads, extreme weather conditions, and various environmental factors. Special steel's exceptional strength, corrosion resistance, and longevity make it a preferred choice for such applications, ensuring the safety and reliability of rail systems. In summary, special steel significantly contributes to the railway industry by providing the necessary strength, durability, and resistance to wear and tear for various components and structures. Its use in rails, wheelsets, and infrastructure elements enhances the efficiency, reliability, and safety of rail systems, ultimately benefiting passengers, freight transport, and the overall transportation sector.

- Q: What are the requirements for special steel used in textile machinery?

- The requirements for special steel used in textile machinery include high strength and durability, excellent corrosion resistance, good wear resistance, and the ability to withstand high temperatures and pressures. Additionally, the steel should have good machinability and be able to maintain dimensional stability under various operating conditions.

Send your message to us

Ral 9014 PPGI for Exporting Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords