Q235B spiral pipe can be processed inside and outside anti-corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

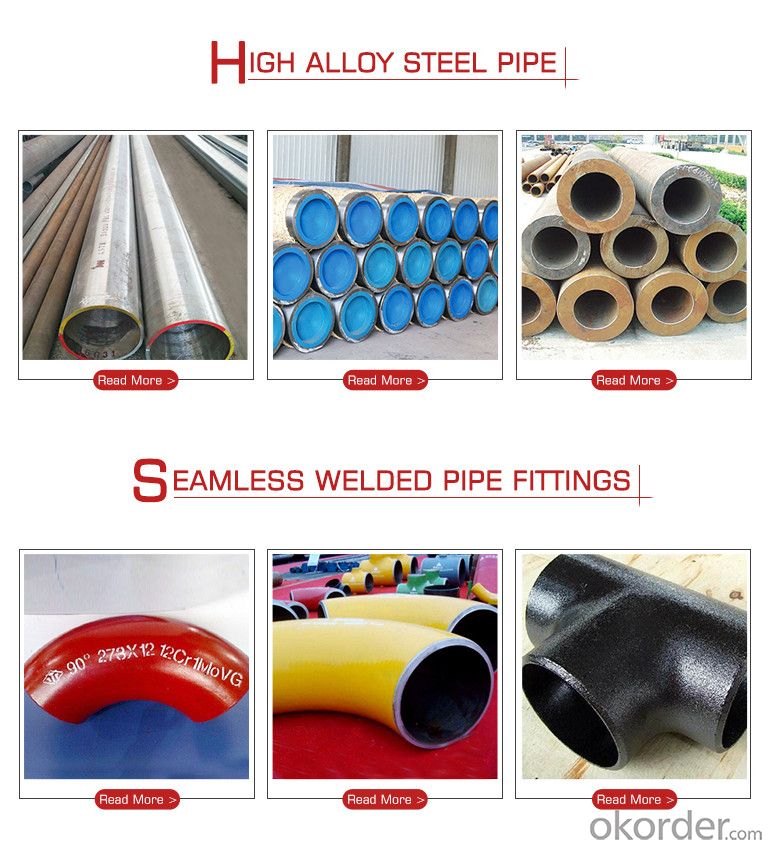

Our main products are: seamless steel tube (hot rolling, cold drawing);Spiral steel tube;Straight seam steel tube;Heat expanding steel tube;Large diameter thick wall steel tube;Alloy steel tube;Anti-corrosion and heat preservation steel pipe.Scope of seamless steel tube: diameter 57mm-910mm wall thickness 2.0mm-26mm;Double-sided submerged arc welding spiral steel tube: diameter: 219mm-3600mm; wall thickness: 6.0mm-30mm;Straight seam resistance welded steel tube (ERW) : diameter 21.3mm-457.2mm wall thickness 1.8mm-14.27mm and straight seam double-sided submerged arc welding pipe: diameter 310mm-3200mm wall thickness 6mm-60mm;Thermal expansion seamless steel tube: diameter 245mm-920mm wall thickness 6.0mm-34mm;Large diameter thick wall steel tube: diameter 351mm-3600mm wall thickness 26mm-80mm. Seamless steel tube execution standard: GB/T8162 8163 3087 5310 6479 9948 5312.Helical steel tube executive standard: GB/T9711.1 9711.2 SY/T5037 5040 APTSPEC 5L.Straight seam steel pipe standards: GB/T3091971113793APISpec5L.Thermal expansion steel pipe executive standard: GB/T8162 8163 3091.Large diameter thick wall steel pipe executive standard: GB/T3091 3092 14980 13793.Alloy steel pipe standards: GB3087, 5310, 6479, 9948 SY/T6194API5CTAPI5LAPI5BASTM53M?ASTMA106 ASTMA213/213 m DIN17175.

According to customer requirements, the company can undertake steel tube of the single and double fusion bonded epoxy (FBE), double polyethylene powder (2 PE pipe) and three layers of polyethylene (3 PE steel pipe), double polypropylene (pp) and polypropylene (pp), three layer of epoxy coal tar anti-corrosion coating pipeline anticorrosion engineering and IPN8710 polymer anticorrosive coatings, cement mortar pipe wall corrosion pipe internal coating such as a variety of anti-corrosion structure of directly buried steel pipeline anticorrosion engineering and rock wool insulation sets of steel, black/yellow leather jacket polyurethane foam insulation pipe engineering, execution DIN30670?30671, SY/T4013 0315 standard, is widely used in oil, natural gas, gas, water and other long transmission pipelines and petrochemical enterprises urban central heating pipe network, gas pipe network and other projects, products with high strength, high pressure, easy to install, low cost, long service life and many other advantages, by the user's praise.

- Q: What are the factors that affect the lifespan of steel pipes in different environments?

- The factors that affect the lifespan of steel pipes in different environments include the pH level of the surrounding soil or water, presence of corrosive chemicals, humidity and moisture levels, exposure to extreme temperatures, mechanical stress or pressure, and the quality of protective coatings or corrosion inhibitors applied to the pipes.

- Q: Can steel pipes be used for conveying solids?

- Yes, steel pipes can be used for conveying solids. Steel pipes are commonly used in industries such as mining, construction, and agriculture to transport various solid materials, including ores, gravel, sand, and grains. The durability and strength of steel make it a suitable material for handling solid substances efficiently and ensuring their safe transportation.

- Q: Are steel pipes suitable for wastewater treatment plants?

- Yes, steel pipes are suitable for wastewater treatment plants. Steel pipes are known for their durability, corrosion resistance, and high strength, making them ideal for handling the demanding conditions of wastewater treatment plants. They can effectively transport and contain wastewater without any structural or functional issues, ensuring efficient and reliable operation of the treatment process.

- Q: How do you calculate the buoyancy of submerged steel pipes?

- To calculate the buoyancy of submerged steel pipes, you need to determine the weight of the displaced fluid. This can be done by multiplying the volume of the submerged portion of the pipe by the density of the fluid. The buoyant force is then equal to the weight of the displaced fluid.

- Q: Can steel pipes be recycled and used for other purposes?

- Yes, steel pipes can be recycled and used for other purposes. Steel is a highly recyclable material, and steel pipes are no exception. Recycling steel pipes helps to conserve natural resources and reduce the demand for new steel production. When steel pipes are recycled, they are typically sent to a recycling facility where they are sorted, cleaned, and processed. The pipes are then crushed into smaller pieces or melted down to be reshaped into new steel products. Recycled steel pipes can be used for a variety of purposes. They can be used in construction projects, such as for building bridges, roads, or buildings. They can also be used in the manufacturing of new steel products, such as automotive parts, appliances, or furniture. Additionally, recycled steel pipes can be used in the energy sector, for example, in the production of wind turbines or oil and gas pipelines. Using recycled steel pipes not only helps to reduce waste and conserve resources but also has environmental benefits. The recycling process requires less energy and produces fewer greenhouse gas emissions compared to the production of new steel. Therefore, recycling steel pipes is a sustainable option that contributes to a circular economy and helps to protect the environment.

- Q: How do you protect steel pipes from external damage?

- One way to protect steel pipes from external damage is by applying a protective coating or paint. This can help prevent corrosion and other forms of physical damage caused by exposure to moisture, chemicals, or rough surfaces. Additionally, using pipe supports and installing guards or barriers can help shield the pipes from potential impact or accidental damage. Regular inspections and maintenance are also crucial to identify and address any signs of damage or wear in a timely manner.

- Q: How do you join steel pipes together?

- Steel pipes can be joined together using various methods, including welding, threaded connections, flanges, and mechanical couplings. The most common method is welding, where the ends of the pipes are heated and fused together using a welding electrode. Threaded connections involve screwing the pipes together using male and female threads. Flanges are used for larger pipes and involve bolting two flanges together with a gasket in between. Mechanical couplings use compression or clamping mechanisms to connect pipes without the need for welding or threading.

- Q: How are steel pipes insulated?

- Steel pipes are typically insulated using various methods such as applying insulation materials like fiberglass, mineral wool, or foam directly onto the surface of the pipes. This insulation helps to prevent heat loss, control condensation, and protect against corrosion. Additionally, some pipes may also be wrapped with reflective foil or jacketed with a protective covering to enhance insulation efficiency and durability.

- Q: How are steel pipes classified based on their thickness?

- Steel pipes are classified based on their thickness into three categories: standard, extra strong, and double extra strong.

- Q: How does the price of steel pipes fluctuate?

- The price of steel pipes fluctuates due to various factors, including changes in raw material costs, supply and demand dynamics, global economic conditions, and market competition. Fluctuations in the price of steel, which is a key component in pipe manufacturing, directly impact the cost of steel pipes. Additionally, shifts in demand for steel pipes in industries such as construction, oil and gas, and automotive can also influence their pricing. Market conditions, such as trade policies and geopolitical factors, can further contribute to price fluctuations. Therefore, the price of steel pipes is subject to constant change, driven by a combination of these factors.

Send your message to us

Q235B spiral pipe can be processed inside and outside anti-corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords