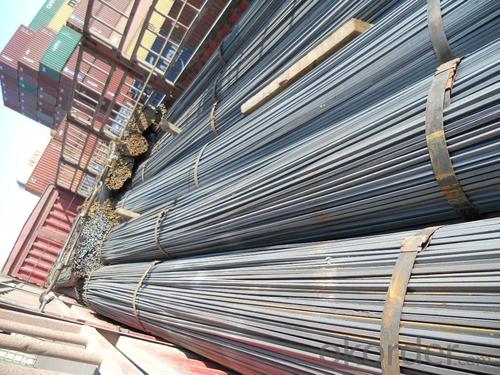

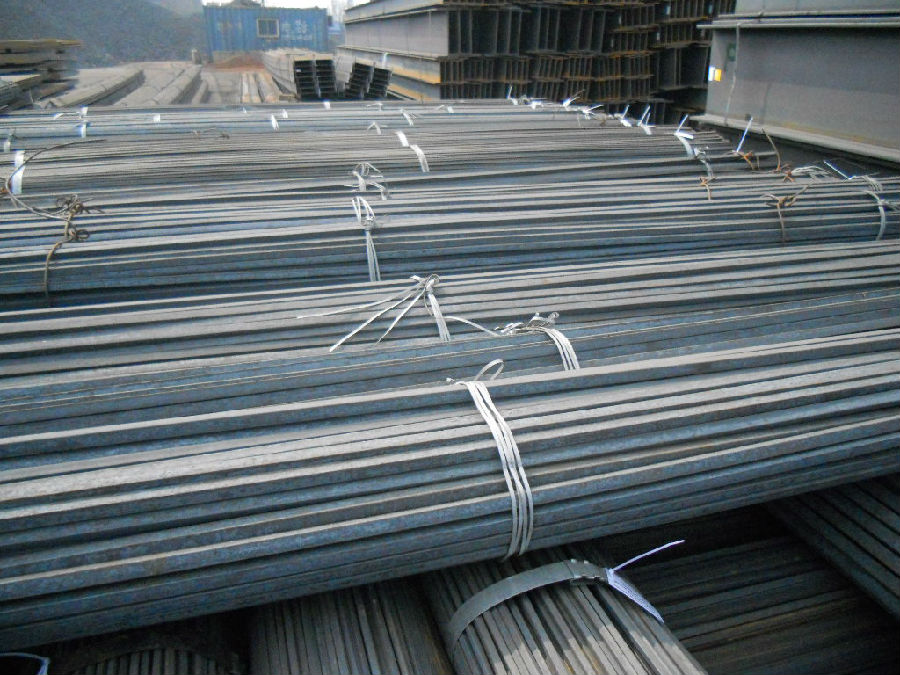

Cold Drawn Square Steel Q235 Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Cold Drawn Square Steel Q195 Q235

Grade: Q195, Q235

Size: 8-100mm

Length 6-12m

Best quality & Low price

Cold Drawn Square Steel Q195 Q235

Grade: Q195, Q235

Size: 8-100mm

Length 6-12m

Mild steel is sometimes referred to as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels

do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most

fabrications. Mild Steel can be easily cut or drilled to meet your requests.

square bars are widely used for machine-made industry,chemical industry,spin,shipping industry, architecture,

food industry, housed.

| Technique | Hot rolled |

| Standard | GB,JIS,ASTM |

| Steel material | Q195 Q235B Q275 20Mnsi 3SP 5Sp |

| Size | 50mm x 50mm-150mm x 150mm or as per customers' requirement |

| Length | 6m-12m as standard |

| Application | Construction,Metallurgy,Carbon structural steel, Alloy steel, Gear steel, etc. |

| Quality | First quality |

| Delivery time | 25-45days or according to the order quantity or negotiation |

| Payment Terms | L/C, T/T |

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the different techniques for using a steel square in metalworking fabrication?

- There are several techniques for using a steel square in metalworking fabrication. Some common techniques include using it as a measuring tool for marking and scribing lines, checking for squareness and right angles, laying out angles and bevels, and as a guide for cutting and sawing. The steel square is a versatile and essential tool in metalworking, helping ensure accuracy and precision in various fabrication processes.

- Q: How do you use a steel square to find the length of a line?

- To use a steel square to find the length of a line, you can follow these steps: 1. Place the steel square against one end of the line, ensuring that one side of the square aligns perfectly with the line. 2. Hold the square firmly in place and extend the other side of the square along the line. 3. If the line is longer than the length of the square, you will need to move the square along the line, keeping the aligned side in position, until you reach the end of the line. 4. Once the square is aligned with the end of the line, measure the distance from the aligned side of the square to the end of the extended side. 5. This measurement will give you the length of the line. It is important to note that using a steel square may not be as accurate as using a measuring tape or ruler, especially for longer distances. Steel squares are primarily used for measuring right angles and checking for squareness, so if precise measurements are required, it is recommended to use a more precise measuring tool.

- Q: Can a steel square be used for measuring the thickness of plastic?

- Using a steel square to measure the thickness of plastic is not possible. The main purpose of a steel square is to measure right angles and check for squareness. It is not intended for accurately measuring material thickness, particularly when it comes to flexible and variable substances like plastic. For precise measurements of plastic thickness, it is recommended to utilize specialized tools such as calipers, micrometers, or thickness gauges. These tools are specifically designed to accurately measure thickness in different materials, including plastic.

- Q: How do you use a steel square to mark out parallel lines on uneven surfaces?

- To use a steel square to mark out parallel lines on uneven surfaces, you would first place the square on the surface with one edge aligned with the desired starting point of the parallel lines. Then, using a pencil or scribe, mark a line along the edge of the square. Next, move the square along the surface, aligning the marked line with the opposite edge of the square, and mark another line. Repeat this process until you have marked out all the parallel lines you need. The steel square helps maintain the parallel alignment despite the unevenness of the surface.

- Q: Can a steel square be used for checking the alignment of door frames?

- Checking the alignment of door frames can be done using a steel square. A steel square, which is also referred to as a combination square, is a tool with a ruler and an adjustable square head. It is commonly utilized in woodworking and carpentry to measure, mark, and examine angles. To check the alignment of a door frame with a steel square, the first step is to ensure that the square is set at a 90-degree angle. Afterward, the square should be placed against the inner edge of the door frame, ensuring that it is flush with both the top and side of the frame. By visually inspecting the alignment of the square with the frame, it is possible to determine if the frame is perfectly square or if any adjustments are required. Additionally, a steel square can also be employed to check the hinge side of the door frame. By placing the square against the inner edge of the frame and extending it along the frame's length, it is possible to ascertain if it is straight and free from warping. This is crucial for the proper installation and smooth operation of the door. In conclusion, a steel square is a valuable tool for checking the alignment of door frames. Its versatility and precision make it a dependable choice for carpenters, contractors, and homeowners alike.

- Q: Can a steel square be used for metalworking?

- Yes, a steel square can be used for metalworking. Steel squares are commonly used in metalworking to measure and mark angles, ensure accurate cuts, and check the squareness of corners. They are versatile tools that are widely used by metalworkers for various tasks such as layout work, welding, and fabrication processes.

- Q: Can a steel square be used for measuring angles in welding?

- Yes, a steel square can be used for measuring angles in welding. A steel square is typically L-shaped and has a 90-degree angle, making it an appropriate tool to measure and verify right angles in welding. It can be used to ensure accuracy and precision when welding joints and corners.

- Q: Can a steel square be used for pergola layout and construction?

- Yes, a steel square can be used for pergola layout and construction. A steel square is a versatile and durable tool that can help ensure accurate measurements and angles during the construction process. It can be used to layout and mark the positions of posts, beams, and rafters, as well as to check for squareness and levelness. Additionally, a steel square can aid in creating precise cuts and joints, leading to a well-built and structurally sound pergola.

- Q: How do you use a steel square to measure and mark out crosscuts?

- To measure and mark out crosscuts using a steel square, the following steps are typically followed: 1. Start by setting up your workpiece securely on a workbench or saw horses, ensuring it is clamped or held in place. 2. Measure and mark the desired length of the crosscut on the edge of the workpiece using a measuring tape or ruler. 3. Position the steel square against the edge of the workpiece, making sure the long arm touches the edge and the short arm extends over the face of the workpiece. 4. Align the square by adjusting its position until the long arm is parallel to the marked line on the edge of the workpiece. 5. Mark the exact location of the crosscut by using a pencil or sharp knife to draw a line along the edge of the steel square's short arm, extending across the face of the workpiece. 6. Ensure accuracy by double-checking your measurements before proceeding with the cut. If necessary, make any adjustments to the position of the steel square. 7. Finally, make the crosscut carefully using a suitable saw, such as a handsaw or circular saw. Remember to follow safety precautions and use the appropriate technique for the particular saw you are using. By following these steps, you can achieve precise and accurate crosscuts by effectively utilizing a steel square.

- Q: Can a steel square be used for measuring pipe sizes?

- No, a steel square cannot be used for measuring pipe sizes as it is primarily used for measuring right angles and not suitable for measuring the diameter or circumference of a pipe.

Send your message to us

Cold Drawn Square Steel Q235 Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords