PVDF Coated Aluminum Coil for Aluminum Composite Panel - Aluminum Coil Home Depot Lowe's

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Grade: 1100/1050/1060 O - H112

Thickness: 0.25mm-4.0mm

Widths: 35mm-1700 mm

Coating: PVDF

Pre-painted Aluminum Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,6061,6063,8011,etc Temper: 0-H112 |

Widths | 35mm -1700 mm available |

Thickness | 0.25mm - 4.0mm |

Coating | PE, PVDF or Customize |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm – 1270mm |

Color | Customized |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Aluminum Suspended Ceiling ,Aluminum Sandwich Panel, Wall Cladding Panel, Roller Shutter, Metal Roofing, Conner Bead, etc |

Coating Type

FAQ of PVDF Coated Aluminum Coil for Aluminum Composite Panel

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: How are aluminum coils cleaned and maintained?

- Aluminum coils are typically cleaned and maintained by following a few key steps. Firstly, any loose debris or dirt should be removed using a soft brush or vacuum cleaner. Then, a mild detergent solution or a specialized coil cleaner can be applied to the coils, followed by gentle scrubbing with a soft brush to remove any stubborn dirt or grime. It is important to rinse off the cleaning solution thoroughly using a hose or pressure washer, ensuring no residue is left behind. Regular maintenance includes checking for any signs of damage or corrosion, and if required, applying a protective coating or lubricant to prevent future issues.

- Q: How are aluminum coils processed for specific surface finishes?

- Aluminum coils are processed for specific surface finishes through various methods such as mechanical polishing, chemical etching, anodizing, or coating. These processes help achieve desired appearances, textures, and protective coatings on the aluminum surface.

- Q: Is it possible to recycle aluminum coils without any loss in their quality?

- <p>Yes, aluminum coils can be recycled without damaging their quality. Aluminum is one of the most recycled materials due to its ability to be recycled indefinitely without any loss in quality. The recycling process involves melting the aluminum, which can then be reshaped into new coils or other products. This process is energy-efficient and environmentally friendly, as it requires significantly less energy than producing aluminum from raw materials. Recycled aluminum maintains the same strength, durability, and appearance as new aluminum, making it a sustainable choice for various applications.</p>

- Q: Are there any specific guidelines for the storage of aluminum coils?

- Aluminum coils have specific guidelines for storage, and here are some key considerations: 1. When storing aluminum coils, it is necessary to place them in a clean, dry, and well-ventilated area. The storage facility should be free from excessive humidity, direct sunlight, and temperature fluctuations. 2. To prevent damage, handle the coils with care. Appropriate lifting equipment should be used to lift them, avoiding any bending or deformation. 3. Proper support is crucial when stacking the coils to prevent distortion or collapse. It is recommended to stack the coils horizontally on a flat surface, preferably on pallets or racks. Sufficient space should be left between each coil to allow for ventilation. 4. Protect the coils from dust, dirt, and moisture. Cover them with suitable protective materials like plastic sheets or tarpaulins to prevent contamination or oxidation. 5. Labeling each coil with relevant information, such as the alloy type, size, and production date, is advisable. This helps with easy identification and efficient inventory management. Additionally, maintaining an organized storage system prevents damage and enables efficient retrieval. 6. Regular inspection and inventory checks are necessary to identify any signs of damage or deterioration. Rotate the coils to ensure proper usage and avoid prolonged storage that could affect quality. It is important to note that these guidelines may vary depending on the specific requirements of the manufacturer or supplier. Therefore, it is advisable to consult the manufacturer's recommendations or seek professional advice for the storage of aluminum coils.

- Q: Are aluminum coils resistant to chemicals?

- Yes, aluminum coils are generally resistant to chemicals. Aluminum has a natural oxide layer that forms on its surface, which provides a protective barrier against many chemicals. This oxide layer helps to prevent corrosion and degradation of the aluminum coils when exposed to different substances. However, it is important to note that some chemicals can still have an adverse effect on aluminum, particularly strong acids or alkalis. In such cases, additional protective coatings or treatments may be necessary to enhance the chemical resistance of the aluminum coils.

- Q: Can aluminum coils be customized or fabricated into specific shapes?

- Indeed, it is possible to customize or fabricate aluminum coils into desired shapes. Aluminum possesses remarkable formability and can be effortlessly shaped through diverse fabrication techniques such as rolling, bending, stamping, and extrusion. By employing these processes, aluminum coils can be converted into specific forms like sheets, plates, tubes, and profiles to cater to the unique demands of different applications. Moreover, aluminum can also be welded, joined, or cut to further tailor its shape and dimensions. The adaptability of aluminum coils in terms of customization renders them highly favored across various industries, including automotive, aerospace, construction, and manufacturing.

- Q: Are there any specific guidelines for the installation of aluminum coils?

- Yes, there are specific guidelines for the installation of aluminum coils. These guidelines typically include recommendations for proper handling, storage, and transportation of the coils, as well as instructions for their secure attachment, alignment, and electrical connections. It is important to follow these guidelines to ensure the efficient and safe installation of aluminum coils.

- Q: What are the different coil pattern options for aluminum coils?

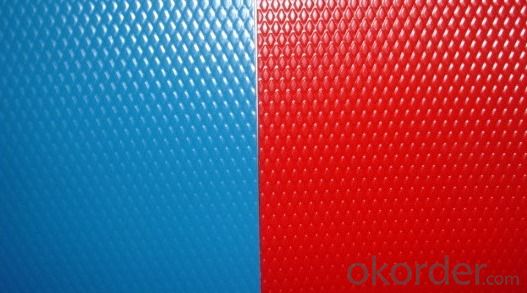

- Aluminum coils offer diverse coil pattern options to cater to specific applications and desired aesthetics. Here are some commonly used patterns: 1. Stucco Pattern: This option imitates the appearance of stucco with a textured, raised surface. It offers durability and a non-slip surface, making it suitable for outdoor surfaces and flooring. 2. Diamond Pattern: Featuring small diamond-shaped embossed designs, this pattern provides an attractive and slip-resistant surface. It finds applications in stair treads, walkways, and decorative panels. 3. Wood Grain Pattern: This pattern replicates the natural wood grain, making it an appealing choice for architectural and interior design purposes. It is commonly used in wall cladding, ceiling panels, and furniture. 4. Checkered Pattern: Also known as the checker plate pattern, it showcases a grid of raised diamonds or squares. This pattern offers excellent slip resistance and finds utility in safety-focused applications like ramps, industrial flooring, and staircases. 5. Plain Smooth Pattern: This versatile pattern has a flat, smooth surface without any embossed designs. It suits various applications such as roofing, gutters, and general fabrication. 6. Ribbed Pattern: Consisting of parallel lines or ribs along the coil's length, this pattern provides enhanced strength and rigidity. It is commonly used in truck bodies, trailers, and industrial equipment. These examples highlight the array of coil pattern options available for aluminum coils. The appropriate pattern selection depends on project-specific requirements, including functionality, durability, and aesthetic preferences.

- Q: Can aluminum coils be anodized for enhanced durability?

- Yes, aluminum coils can be anodized for enhanced durability. Anodizing is a process that creates a layer of aluminum oxide on the surface of aluminum, making it more resistant to corrosion, wear, and scratches. This layer also provides added protection against UV rays and harsh environmental conditions. By anodizing aluminum coils, they become more durable and can withstand prolonged use in various industries such as construction, automotive, and electronics. Additionally, anodized aluminum coils can be further treated with additional coatings or finishes to enhance their appearance and offer further protection. Overall, anodizing aluminum coils is a widely used and effective method to enhance their durability and prolong their lifespan.

- Q: Can aluminum coils be used in the production of military equipment?

- Yes, aluminum coils can be used in the production of military equipment. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various military applications, such as aircraft components, armored vehicles, and weapon systems. Its strength to weight ratio and ability to withstand harsh environments make it an ideal choice for military equipment manufacturing.

Send your message to us

PVDF Coated Aluminum Coil for Aluminum Composite Panel - Aluminum Coil Home Depot Lowe's

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords