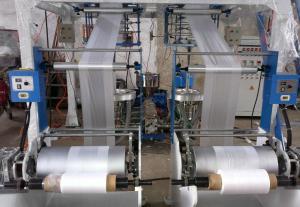

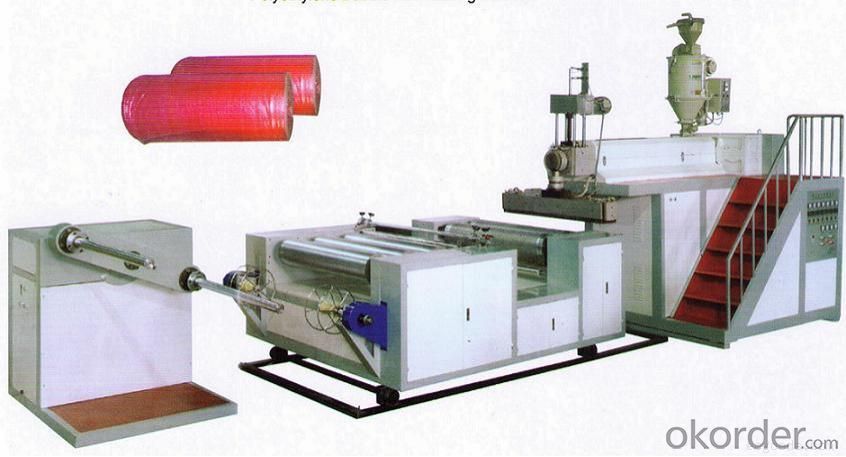

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STRUCTURE FEATURES:

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality. This machine set has such features as scientific and reasonable structure design, Smooth and reliable running and convenient operation and maintenance.

Polyethylene air-cushion film is a kind of packing materials which has been widely used at present. It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing, household wares, post parcel, precise instrument, bicycle, polyurethane furniture, etc.

TECHNICAL PARAMETER:

Model | JSM-650 | JSM-1000 | JSM-1200 | JSM-1500 | JSM-2000 |

Screw Diameter | Φ55mm | Φ60mm | Φ65mm | Φ80mm | Φ90mm |

Film Width | 650mm | 1000mm | 1200mm | 1500mm | 2000mm |

Max. Output | 25kg/h | 40kg/h | 50kg/h | 65kg/h | 80kg/h |

Main Motor Power | 11kw | 15kw | 18.5kw | 22kw | 37kw |

Power | 30kw | 48kw | 55kw | 70kw | 105kw |

L/D | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 |

Power Supply | 380/3/4/50 (Volt/Ph/Line/Hz) | ||||

Weight | 3500kg | 4000kg | 4200kg | 4500kg | 7000kg |

Overall Dimension (L*W*H) | 9.0×3.0×2.5m | 9.0×3.0×2.5m | 9.5×3.8×2.5m | 10×4.0×2.6m | 11.5×4.8×4.0m |

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q: What is the adjustment method of China's extrusion machine die?

- (4) lamp alignment: suitable for polythene plastic wires and cables. Use light to illuminate the insulating layer and sheath, observe the upper, lower, left and right sides of the thickness, adjust the screw to the die until it is even, then screw the screws.

- Q: Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Extrusion machine operating procedures, specific points, thank you!

- 6, the speed from low to high, added to the normal speed, is strictly prohibited high-speed car, observe the instrument on the current value and temperature is normal, in case the current is too large, cause the heater to burn.7, when lifting the disk, we should pay attention to the limit of the rise and fall, not too high or too low, when there is an electrical limit, shall not exceed the limit.8 when feeding to the hopper, be careful not to enter the metal, and do not use a screwdriver or a metal bar to poke the plastic into the screw.9 check the dry test machine, should be equipped with rubber insulation plate, otherwise, no driving.10 before driving, should check whether the ground location is good, grounding resistance should be measured regularly, not higher than 4 Europe; equipment whether there is noise and other anomalies, if there is a problem, repair and reuse.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

Send your message to us

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords