PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

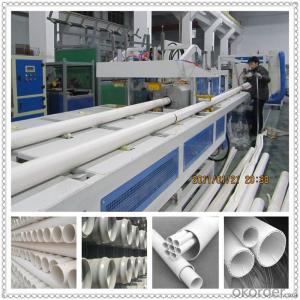

PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

Machine Application

Such qualified extrusion line is mainly for producing PVC agricultural water/ building water/cable pipes, etc.

It can process various soft and rigid PVC, especially process powder directly into pipe shape.

Whole line consists of material feeder, conical twin screw extruder, die head, vacuum calibration tank, haul-off, cutter, stacker or belling machine, etc.

Machine List

| No. | Item | Qty |

| 1 | Screw feeder | 1 set |

| 2 | SJZ 80/156 Conical twin screw extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum calibration tank | 1 set |

| 5 | Three claws haul-off | 1 set |

| 6 | Planetary cutter | 1 set |

| 7 | Stacker | 1 set |

| Option | Belling Machine | 1 set |

Annotation: Some configuration and material can be designed according to customers’ requirement. | ||

Improvements made on Conical twin screw extruder:

1.Gear box bearings: NSK, Japan

2.Gear box: Jiangyin Brand

3.Special design of screw & barrel

4. All connector, nut etc all adopt nickel plated

Electrical part:

1. Solid state relay: Crydom, USA brand instead of common AC contacto

2. Siemens PLC controlling system

3. Pressure sensor: Dynisco,USA

4. Sayu cooling fan, Taiwan brand

5. ABB550 inverter

6. Siemens Beide motor

7. Low voltage component: Siemens/Schneider/LG

Corresponding Advantages:

1. Ensuring long-time stable operation & long service life

2. Compact structure, low noise, high bearing capacity, high transmission efficiency, ensuring long-time stable operation & long service life

3. Heating is controlled by Solid State Relay (S.S.R), realizing stable heating; (SSR) no spark & no noise improve safe production.

4. Siemens PLC controlling system with reliable technology, automatic and intelligent functions for centralized control and monitoring extrusion lines, which helps easy operation.

5. International brand of electronic parts guarantee stable operation and long service life.

Technical Data

Extruder | Pipe ranger (mm) | Max.output (kg/h) | Max.hauling speed (m/min.) | Extruder powder (KW) |

CAMX51/105 | 16-40 Dual | 120 | 10 | 18.5AC |

CAMX65/132 | 20-63 Dual | 250 | 15 | 37AC |

CAMX51/105 | 20-63 | 120 | 15 | 18.5AC |

CAMX65/132 | 50-160 | 250 | 8 | 37AC |

CAMX65/132 | 63-200 | 250 | 3.5 | 37AC |

CAMX80/156 | 160-315 | 350 | 3 | 55AC |

CAMX92/188 | 315-630 | 800 | 1.2 | 110DC |

Product picture

FAQ:

Q: What price terms you offer?

A: FOB, CIF, EXW, L/C at sight and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Tangqiao Town, Zhangjiagang City, Jiangsu Province, China. About 2.5 hours from Shanghai Pudong International Ariport! We will arrange to pick you up from Shanghai.

A: Yes, our engineers will guide machine installation and train your workers.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- This is often called information information, this website. Reference: Fox information Qilu Chemical City PE market by the petrochemical price driven price continues to rise, 7042 no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: What is the adjustment method of China's extrusion machine die?

- (3) line to die: suitable for small section of wire and cable adjustment. Pass the wire through the mold core, connect to the traction line, then run the glue and fine tune it. When the glue is running, adjust the screw and the traction speed, start the car, take the line sampling, and then stop to observe the thickness of the plastic layer of the sample is even, repeated several times until the tune until so, and then tighten the screws

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches