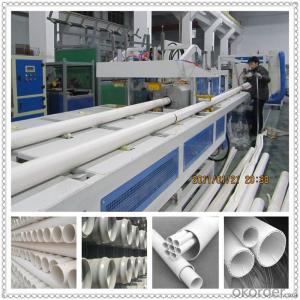

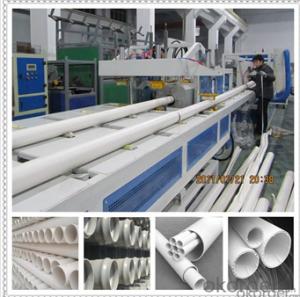

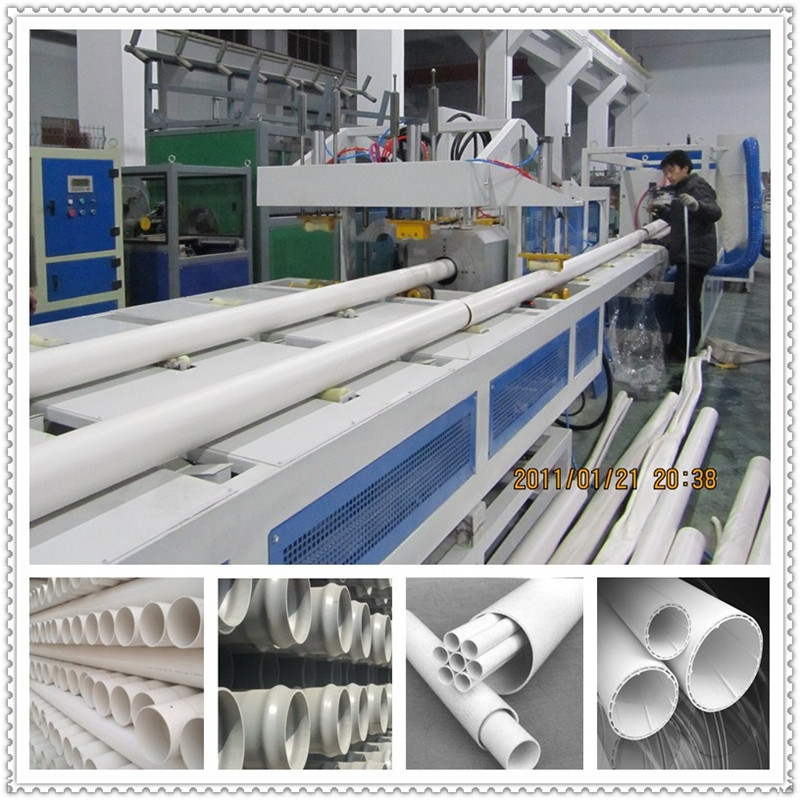

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New high output PVC small pipe machine wire conduit pipe making machine Double pipe production line PVC two pipe extrusion line PVC wire pipe extruder machine

The production line is development with the advanced technology of West Europe by our company. The main machine is SJSZ-51 or SJSZ-65 conical twin screw extruder is equipped with double-tube separate-control stainless steel spraying calibration.It avoids waste condition when one tube is adjusted and the other one is affected.

Small PVC wire pipe machine Production Line details:

1.AC motor,ABB frequency speed governor, Japanese RKC temperature controller, Schneider contactor.

2.Screw Nitriding treatment,hardness HV740-940,surface roughness Ra≤ 0.8um.

3.Barrel air-cooled cooling method, nitriding depth of 0.5- 0.7mm, hardness of HV860 or more, the surface roughness Ra ≤ 1.6um.

4.Die head material,High quality steel by quenching and tempering.Structure,Where contact with the materials hard chrome plating.Bolts level,12.9 high strength bolts.

5.Two Vacuum calibration tank material:Stainless steel.

6.Double Caterpillar adjusting method: pneumatic compress device.

7.Double cutter: Most cutting times,20 times/min;With strong waste clean device. Equipped with a meter installation, meter size is accurate.

8.Double stacker: Pneumatic flip, soft rubber, to prevent pipe surface scratch.

9.All electrical parts adopt world famous brand product.

Extruder For PVC small diameter conduit Pipe machine :

| Item | SJSZ-51 | SJSZ-65 |

| Diameter of screw(mm) | 51/105 | 65/132 |

| Screw rotation speed(rpm) | 1-45 | 1-35 |

| Power of Main engine(kw) | 18.5 | 37 |

| Production capacity(kg/h) | 80-150 | 250-300 |

| Net weight(kg) | 3200 | 4000 |

| Dimensions(mm)(L*W*H) | 3600*1100*2100 | 4235*1520*2450 |

We are the manufacturer specialized in plastic machine manufacture for many years,our products are exported to many countries.If you are interested in our products,please contact us at any time.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- The recipe is either too large or too small. Do you mean that the tension is not enough, transverse or vertical?

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

Send your message to us

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords