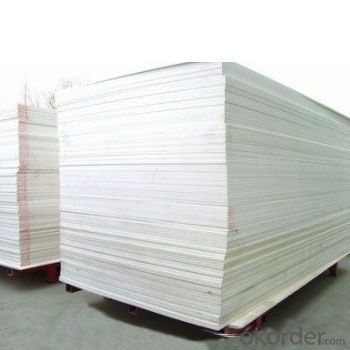

Plastic Sheets - PVC Foam Sheet Waterproof and Mould Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

20mm pvc rigid foam board

Specifications

1. Waterproof and mould proof.

2. Widely used in kitchen and washroom cabinet.

3. Thickness from 1mm to 40 mm, different density.

We are specialized in manufacturing PVC foam board. There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise. And now we have 6 production line for PVC foam board,

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware.Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing,

· (UL-94 VO flame rating), perfect for tradeshow and exhibit hall use

3. Heat preservation,

4. Sound-insulated

5. Insulation.

6. Non-corrosion.

7. Tough, rigid with the high impact strength,

8. Stable color retention

9. Dampproof.

10. Anti - deformed.

11. flexibility good , not broken on one direction

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet,

Commodity:

1 width: 1220mm, 2050mm

2 Length: 2440mm or as per your requirement,

3 Thickness: From 1mm to 40mm

4 Density: From 0.35 to 1.05 g/cm^3

Packing details:

PE bag or carton PE BAG

packing thickness 16mm, size 1220*2440mm, 500 sheets in one 20 feet container

Testing Item Unit Testing Result

Density g/cm 3 0.35-1.05

Tensile Strength MPa 12-20

Bending Intensity MPa 12-18

Bending elasticity Modulus MPa 800-900

Impacting Intensity KJ/m 2 8-15

Breakage Elongation % 15-20

Shore hardness D. D 45-50

Water Absorption % ≤1.5

Vicar Softening Point 73-76

Fire Resistance Self-Extinguishing Less than 5 seconds

Specification 1220X2440(mm),915X1830(mm),1560X3050(mm),2050*3050mm,Can be produced as clients' desire)

Colour White, red, yellow, blue, green, black, etc. (Can be produced as clients' desire)

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: 1,If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

2,Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit

Factory picture

- Q: Are plastic sheets waterproof?

- Yes, plastic sheets are typically waterproof as they are designed to repel water and prevent it from seeping through.

- Q: How do you type on a plastic board?

- Transfer processing by thermal transfer machine a processing (heating, pressure) will transfer film exquisite pattern transfer on the product surface, forming the ink layer and product surface dissolved into one, realistic and beautiful, greatly improve the product grade. But because of the high technology content, many materials need to be imported.

- Q: How should the plastic cutting boards be cleaned?

- Vinegar disinfection: cut the fish cutting board, just wash, sprinkle a little vinegar on the surface, put it in the sun to dry, and then rinse with water, there will be no smell.In addition, there are two points to remind you is: first, no matter what kind of disinfection method is used, we must first break the plate clean. Two cut and cooked food should be separated from different chopping boards. Only in this way can better prevent the spread of bacteria

- Q: I have a 30 gallon plastic bucket that I cut a large square out of it and I have molded the acrylic sheet to the right shape, but is there anyway I can bond the acrylic to the plastic? It needs to be water proof and not leech any chemicals. It will be filled up with water and will hold some fish.

- All the plastic buckets I've seen so far are from PA, PP or PE - plastics chosen for their chemical inertness, which in turn also means that they're d*mn near impossible to glue (pretreatment with hot concentrated nitric acid is among the more accessible methods....). As is acrylic, btw. You might be able to weld them (chemically or thermally), but I wouldn't trust this weld if I did it for the life of the fish. If the overlapping area is large enough and the acrylic sheet goes on the inside of the bucket (so that the water pressure actually compresses the seam), you might try fish tank silicone. It won't really glue the parts together, but might stick well enough (probably until someone tries to poke it :-( ). But I doubt that you'll get that stuff in oe of the big box stores - ordinary builder's silicone or bathroom silicone are no good - they'll leach acetic acid and, in case of bathroom silicone, fungicides.

- Q: i'm baking a chocolate cake, but to keep the cake from sticking to the pan, i have to use a baking sheet, i happened to not having it at the moment, can i just use a plastic wrap on the pan and pour the batter in and bake it in the oven? thanks :]

- NO plastic wrap will melt and ruin it. I'd use butter and flour to coat the pan or cooking oil and flour or shortening and flour or any nonstick cooking spray. You might be able to use tin foil or wax paper but never plastic wrap it will melt into your cake and stick to the pan and ruin your baking pan.

- Q: im after some plastic sheets at least 2mm thick im making me own pet tank for snails if you get me the bigger n better the sheets n cheaper the better do you know any good onlines places to order from

- 2mm is pretty thin. If you don't mind going with 4-6mm, then you can get Acrylic (plexiglass) sheet. If there is a plastics processing company near you, you may be able to get Lexan (Polycarbonate) at a pretty good price. You can find the acrylic sheet at most hardware stores. If you screw the pieces together, make sure you slowly drill pilot holes first or you will crack the edges. Other than that, it pretty easy to work with and very durable.

- Q: Can plastic sheets be used for noise reduction barriers?

- Yes, plastic sheets can be used for noise reduction barriers. They are effective in reducing noise transmission and can be easily installed in various settings such as construction sites, factories, or residential areas. Plastic sheets with sound-dampening properties can absorb and block sound waves, providing an effective solution for noise control.

- Q: I would like just a small bit of hard plastic sheets. Probably the size of two A4 size paper. Anyone knows where I can get them in Singapore? (:

- Why would you ask us here in the US?

- Q: For this project I'm working on (Its a robot head I'm making from an old football helmet), and I need to use something for the eye screen piece (Sorta like the eye scanner thingy on the cylon helmets). Something black tinted,see-through (Without every thing being blurry), and most importantly bendable.Do you know where I can find such a thing?

- you could try this, its tinted car window film you can stick it to anything www.OKorder

- Q: i'm trying to decide which rainsuit to buy and i can't figure out what the difference is between the 2, I just don't see how 10mm or 20mm is right, i don't see a rainsuit being made out of 1cm or 2cm thick plactic.

- Are you familiar with the metric system 10mm is just less than 1/2 and 20 mm is just under an inch I looked at the link and I don't think it's a mistake 1.0 mm would be a metre thick and no way is it that.

Send your message to us

Plastic Sheets - PVC Foam Sheet Waterproof and Mould Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords