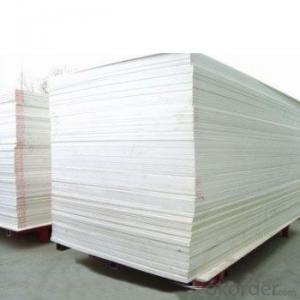

Plastic Sheets - PVC Foam Board for Construction Waterproof and Mould Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer.

Color

Green, black, blue, dark red, yellow, flower gray etc.

Specifications of 4x8 pvc board 3mm pvc foam board:

Waterproof and mould proof

Widely used in kitchen and washroom cabinet

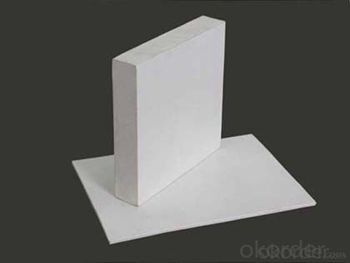

Thickness from 1mm to 30mm, different density

Width: 1220mm

Length: 2440mm or as per your requirement

Density: from 0.4 to 0.9 g/cm3

Introduction:

We are specialized manufacturing PVC foam board/pvc sheet /wpc board.

We have more than 15 production lines could satisfy your requests.

PVC Foam Sheet Specifications:

Thickness :1-40mm

density: 0.35-0.9g/ cm³

Standard size: 1220*2440mm,1560*3050mm,2050*3050mm.915*1830mm

Color: white

Price:factory price

PVC Foam Sheet Applications:

1.Advertising: signs, displays, pop-up displays, exhibition boards

2. Building material: models, partitions, wall cladding, indoor or outdoor decoration,

air conditioning ducts, windows and false ceilings

3. Industrial use: wall claddings, control cabinets and panels, structures for corrosive nvironments, ducts.

4.Transportation:steamboat, airplane, bus, train carriage,roof and carriage inner layer and other industry.

PVC Foam Sheet Processing performance:

1. plastic coating, membrance-stuck and printing

2. with the usual equipment and tools, it can be processed again.

3. welding and bonding

4. cutting and sawing

5. bending when heated-up, thermal forming

6. hole-drilling, Channeling and die cutting

7. nail, wrest and rivet

PVC Foam Sheet Features:

1. light weight, non-absorbent, fire retardant and self-extinguishing

2.Sound insulation,heat insulation,noise absorption,heat preservation and anti-corrosion.

3.Tough,rigid with a high impact strength,not easy to age and can keep its color for long

4. Non-corrosive, non-toxic and chemical resistant

5. Non-warping and stain proof

6. Easy to clean and maintain

7. good plasticity, being an excellent thermoform material

8. sub-light surface and elegant vision

9.suitable to silk screen printing

10.Envioronmental-friendly green and lead-free

FAQ

How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect.

Product pictures

- Q: My house is 50 years old and is lacking in insulation in the garage ceiling. Above the garage are bedrooms. Currently there is 3 of fiberglass with an aluminum vapor barrier within a 2x10 joist. I'd like to put R-30 fiberglass in the cavities but the 25' rolls of insulation are unfaced and the faced R-30 rolls are only in 48 batts. 4' sections are easier to put up but that is not a concern of mine.

- Yea you can do that .Get a good stapler to ad hear the plastic to the wood. No stapler , Use Tacks. or even nails..

- Q: Can I use all this duct tape and plastic sheeting I bought after 9/11 to seal myself off from Ebloa utbreak?

- Wow, it looks like all the cons and Republicans forgot that in the wake of 911, Homeland Security advised Americans were told to stock up on duct tape and plastic sheets to seal the windows of their homes in case Al Qaeda unleashed a deadly gas attack or bio attack on American soil

- Q: I am creating a mini haunted house in my backyard and i wanted to cover my trampoline/full backyard with a large black sheet. Or many small/medium sheets that would cover an area of about 850 Sq. Feet....Anyone know of a website that i could buy this from

- Why not buy yard goods? You can get it any any fabric store; Wal Mart being the cheapest. How about using black nylon net? It comes in 72 inch wide at 57c a yard At Wal Mart. Since everything will be dark net would probably work just fine. Your next best bet would be that plastic sheeting they use for ground cover under plants. If you go with the netting; be sure that is what you ask for do not let them talk you into tulle (pronounced tool) it is much finer, and much more expensive and not as wide.

- Q: Are plastic sheets resistant to chemicals in swimming pools?

- Yes, plastic sheets are generally resistant to chemicals in swimming pools.

- Q: What are the different thickness options available for plastic sheets?

- The different thickness options available for plastic sheets can vary depending on the type of plastic, but commonly range from 0.5mm to 12mm or even thicker for certain applications.

- Q: How do I get the protective film for the kraft paper on the plastic board?

- From the beginning of a corner, slowly with a nail to pull from the corner, then slowly tear, while tear tear in the side roll, some local glue is tight, fingernails, to be up to 6, the 7 lap will be able to hand held, will be able to slowly tear the whole. The key is not to worry, where there are sticky tight place, stop with a nail scratch, not hard to drag.

- Q: Can plastic sheets be used for electrical insulation in high voltage applications?

- Yes, plastic sheets can be used for electrical insulation in high voltage applications.

- Q: They smelled a little different than the surrounding fir and spruce trees but was still kind of a natural odor. The cardboard sheets were also wrapped in the white plastic lattice. Maybe they're something the forestry service uses? But for what??

- and you didn't eat a piece see if you would enjoy your trip? maybe it was a geocache

- Q: Can plastic sheets be used for insulation against electricity?

- Yes, plastic sheets can be used as an insulator against electricity. Plastic is a non-conductive material that does not easily allow the flow of electricity, making it an effective choice for insulation purposes.

- Q: Is the plastic foam roof well insulated?

- Plastic foam board roof insulation effect is better.

Send your message to us

Plastic Sheets - PVC Foam Board for Construction Waterproof and Mould Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords