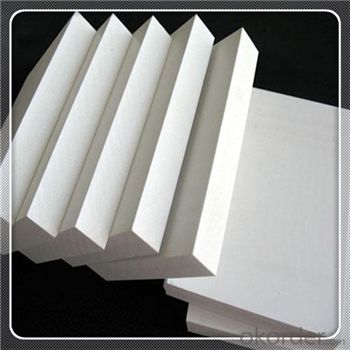

Plastic Sheets - PVC Foam Sheet Waterproof PVC Rigid Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43mm-0.9mm

Product Characters

1.High efficient, high transparent, non-toxic lubricant has certain compatibility with PVC;

2.To help reduce the melt viscosity of PVC products.

3.The course of processing transparent PVC and with the characteristics of longer plasticizing rheological time, higher temperature resistance and oxidation resistance in high temperature (185~230℃) zone, our lubricant can contribute to improve the transparency and luminance of products and then improving the plasticizing temperature and performance of all kinds of materials);

4.Can be used for a long time continually and no precipitation exist, which can help customers to reduce the energy consumption but to increase producing efficiency.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Pictures

FAQ

Q:How to get the price?

A:Please tell me the following information and I'll send you the quotation without delay:

Q:We can get the free samples?

A:Yes,sure.

- Q: I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- 1/2 inch drywall will work just fine

- Q: Can plastic sheets be bent or shaped?

- Yes, plastic sheets can be bent or shaped using various methods such as heat forming, vacuum forming, or cold bending techniques, depending on the type and thickness of the plastic.

- Q: Why should the aluminum-plastic composite board retain the polyethylene plastic not less than 0.3mm thick when cutting the inner aluminum sheet and polyethylene plastic?

- First of all, this value, or this thickness is not expressly provided, is not easy to control.But in the construction of concrete operation process, in order to prevent grooving when scratching the surface layer aluminum plateAt the same time, in order to ensure that corners have a certain strength and toughness,To prevent the process and dry hanging construction, appear outside aluminum plate edge burst.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are often used as a cost-effective and versatile alternative to traditional flooring materials. Plastic sheets can provide durability, water resistance, and easy maintenance, making them suitable for various settings such as garages, basements, and outdoor areas.

- Q: I had to put a plastic sheet over my garden because it has been raining non-stop. When the sun comes out, will I have to take it down, or will the UV rays pass thru it??

- SherylU, Ultraviolet rays will penetrate the plastic sheet.

- Q: Are plastic sheets transparent to UV light?

- Yes, plastic sheets can be transparent to UV light depending on their composition. Some plastics, such as polycarbonate or acrylic, can allow UV light to pass through while others, like PVC or HDPE, may absorb or block UV rays.

- Q: How do plastic sheets compare to acrylic sheets?

- Plastic sheets and acrylic sheets are similar in many ways, as acrylic is actually a type of plastic. However, acrylic sheets have distinct advantages over other types of plastic sheets. Acrylic sheets are more transparent, offer better clarity, and have higher overall strength and durability than most plastic sheets. Additionally, acrylic sheets are more resistant to UV rays, weathering, and impact. They are also easier to shape, cut, and manipulate, making them a popular choice for various applications such as signage, displays, and protective barriers.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: Where can i get good, cheap hard plastic sheets? (stores)?

- What type of plastic are you looking for? Clear plexiglass? Lexan? HDPE? ...

- Q: Can plastic sheets be used for DIY hydroponic systems?

- Yes, plastic sheets can be used for DIY hydroponic systems. They can be used to create troughs or channels to hold the nutrient solution and support the plants. Plastic sheets are often preferred for their durability, affordability, and ease of maintenance in hydroponic setups.

Send your message to us

Plastic Sheets - PVC Foam Sheet Waterproof PVC Rigid Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords