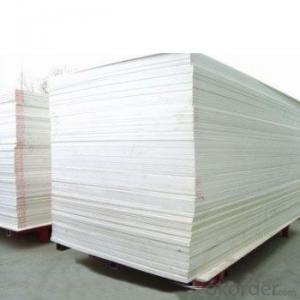

Plastic Sheets - PVC Foam Boards, Sheets, Panels Waterproof, Fireproof

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: Can plastic sheets be used for decorative purposes?

- Yes, plastic sheets can be used for decorative purposes. They are versatile and can be easily cut, shaped, and colored to create various decorative elements such as wall panels, room dividers, signage, and even artwork. Additionally, they are durable, lightweight, and cost-effective, making them a popular choice for both indoor and outdoor decorative applications.

- Q: I had to put a plastic sheet over my garden because it has been raining non-stop. If I leave it up when the sun is out, will the UV rays be able to pass thru it?

- If it is clear plastic, remove it. This could magnify the suns rays and burn your plants. If it is colored plastic, I doubt the rays will go through it.

- Q: where can i get plastic sheets to cover photos?

- You okorder / . You can buy just a few at a time.

- Q: I'm working on a project that requires a semi firm / flexible plastic backing to which I'm going to bond hook and loop material to, using velcro glue. It also needs to be something I can cut and shape easily, with like an exacto knife. Thus far I've looked in Hobby Lobby, JoAnn Fabrics, Walmart and Lowes with no luck. Thanks.

- A okorder / ... HTH, Diane B.

- Q: I have a concret fish pond. like to use plastic sheet as liner. I like to bond them togeter.

- Reasoning escapes me for the gravity will hold the water down which will hold the plastic down. If you are talking about the edges, go to the builders supply and get a tube of PL400(or 500, or 600, or 700) Whatever works on plastic. Read label.

- Q: Are plastic sheets resistant to graffiti?

- Yes, plastic sheets can be resistant to graffiti.

- Q: Toilet melamine partition board, plastic partition board how much is one square metre?

- Do toilet basically use melamine board, moistureproof base material. Seller says waterproof is fake.

- Q: Can plastic sheets be used for window film applications?

- Yes, plastic sheets can be used for window film applications. They are commonly used as a cost-effective alternative to traditional window films.

- Q: You know how dvd cases are made of somewhat flexible plastic? Where can you find sheets of those? (if you even can)

- www.okorder They have all kinds of good plastics. And, they're pretty affordable.

- Q: Can plastic sheets be used for skylight domes?

- Yes, plastic sheets can be used for skylight domes. Plastic materials, such as polycarbonate, acrylic, or fiberglass, are commonly used for skylight domes due to their durability, lightweight nature, and ability to transmit natural light. These plastic sheets are often designed to be impact-resistant, UV-resistant, and provide insulation properties, making them suitable for skylight applications.

Send your message to us

Plastic Sheets - PVC Foam Boards, Sheets, Panels Waterproof, Fireproof

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords