PVC Foam Sheet - High Destination in Construction - Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

Polyvinyl chloride (PVC) is a tough, strong thermoplastic material which has an excellent combination of physical and electrical properties. The products are usually characterized as plasticized or rigid types. Polyvinyl chloride (and co-polymers) is the second most commonly used polyvinyl resins in one of the most versatile plastics.

2.Product Features

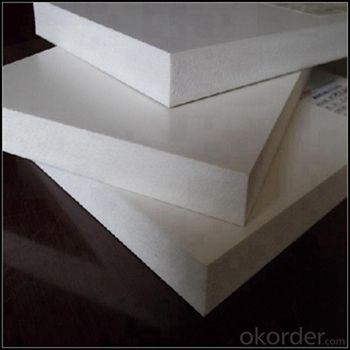

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

•Non-sticky

•Excellent printability with all common printing methods

•Available in a range of tints and transparent and opaque colours

•Range of surface finishes (Glossy/Matt)

3. Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

4.Product details

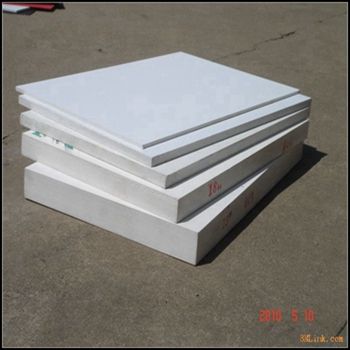

1 | Product | PVC Foam board/sheet/panel | |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on | |

3 | Thickness | 1~ 30mm | |

4 | Density | 0.4~ 0.8g /cm 3 | |

5 | Brand | CMAX | |

6 | Certificate | SGS | |

7 | Weldable | Yes | |

8 | Foam Process | Cellular | |

9 | Packing | Carton box or wooden pallet packing | |

10 | production capability | 10000 pcs per month | |

11 | Life Span | >50 years | |

12 | Flame retardance | self-extinguishing less than 5 seconds | |

5.Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability.

6.Advantages

1. we have our owned PVC foam sheet factory located , China's most popular pvc sheet production area, which make sure the production ability and products high quality.

2. our office located in Beijing , the capital of china , it makes us to keep in touch with buyers timely and very convenient for business talking in our office

3. our overall different department makes us the high standard of working efficiency. such as our solid financial department, sales department, documents department and logistic department .

7. Packing Pictures

- Q: Are plastic sheets resistant to scratching from pets or sharp objects?

- Plastic sheets are generally resistant to scratching from pets or sharp objects, but the degree of resistance can vary depending on the type and quality of the plastic. Some plastics, such as acrylic or polycarbonate, are known for their high scratch resistance and are commonly used in applications where durability is important. However, it's important to note that no plastic is completely scratch-proof, so it's still possible for determined pets or extremely sharp objects to cause some level of scratching or damage.

- Q: What are the different thickness tolerances for plastic sheets?

- The different thickness tolerances for plastic sheets can vary depending on the type of plastic and its intended use. However, in general, common thickness tolerances for plastic sheets range from ±0.003 inches to ±0.020 inches.

- Q: Are plastic sheets resistant to chemicals in swimming pools?

- Yes, plastic sheets are generally resistant to the chemicals found in swimming pools.

- Q: We are doing a classroom simulation and want to build a space shuttle out of PVC pipe and connectors, and black and white plastic sheeting. The students sit inside at the controls. I have seen mockups made from 2 liter pop bottles but this is not that. I saw one at the science teachers convention in San Diego in 2002 but cannot seem to find the directions on how to build my own.

- Your students could probably come up with some great ideas, no matter their age. They will learn more if they design the shuttle. Start them out in groups of 2 or 3 and have them brainstorm ideas (give them the rules for brainstorming). They then select the best ideas and make some simple sketches of how it can work. Them have them bring practice material from home to make a scale prototype. Use the best prototype to create your full size shuttle. Yes - I know this takes more time but they will be developing critical thinking and problem solving skills. Each additional project becomes easier for them as they build their skills. As the teacher you become the facilitator - guiding them through the project. Number1 rule for you is to NEVER NEVER answer their questions. Make them actually think. Ask them, what do you think, where could you look to find the answer, have you tried to ......

- Q: What are we up to?

- You are going to re-create an oil spill, as an experiment...

- Q: What are the different types of plastic sheets?

- There are several types of plastic sheets available in the market, including acrylic, polycarbonate, PVC, PETG, and HDPE sheets.

- Q: I am giving my kitchen cupboards a makeover don't want to paint them so I thought covering them was best any ideas appreciated.thanks in advance

- most Diy stores sell this type of sticky back plastic

- Q: Are plastic sheets easy to clean?

- Yes, plastic sheets are generally easy to clean. They can be wiped clean with a damp cloth or sponge, and some can even be washed with mild soap and water.

- Q: Can plastic sheets be used for swimming pool covers?

- Yes, plastic sheets can be used as swimming pool covers. They are lightweight, affordable, and can effectively prevent debris from entering the pool. However, it is important to ensure that the plastic sheet is durable and UV-resistant to withstand outdoor conditions and provide proper insulation for the pool.

- Q: I have already asked a couple questions about this, and just need to know 2 more things. I know plastic wrap will work, but this is plastic sheet, and is much better,stronger and will still let light in correct? And for a greenhouse, does there need to be a few holes in the walls and roof to let air through, or should it be basically sealed completely? Thanks for any help!

- My answet: Listen to Scott Kelso He is right on

Send your message to us

PVC Foam Sheet - High Destination in Construction - Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords